At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) offers a unique combination of versatility and precision at low temperatures. Unlike conventional methods that rely on intense heat, PECVD uses an energized plasma to drive the chemical reactions needed to create a coating. This fundamental difference unlocks benefits such as the ability to coat heat-sensitive materials, achieve higher quality films with fewer defects, and significantly increase the speed of the coating process.

The true value of PECVD is its ability to decouple reaction energy from thermal energy. This allows for the deposition of high-performance, durable films onto materials and complex components that would be damaged or destroyed by traditional high-temperature methods.

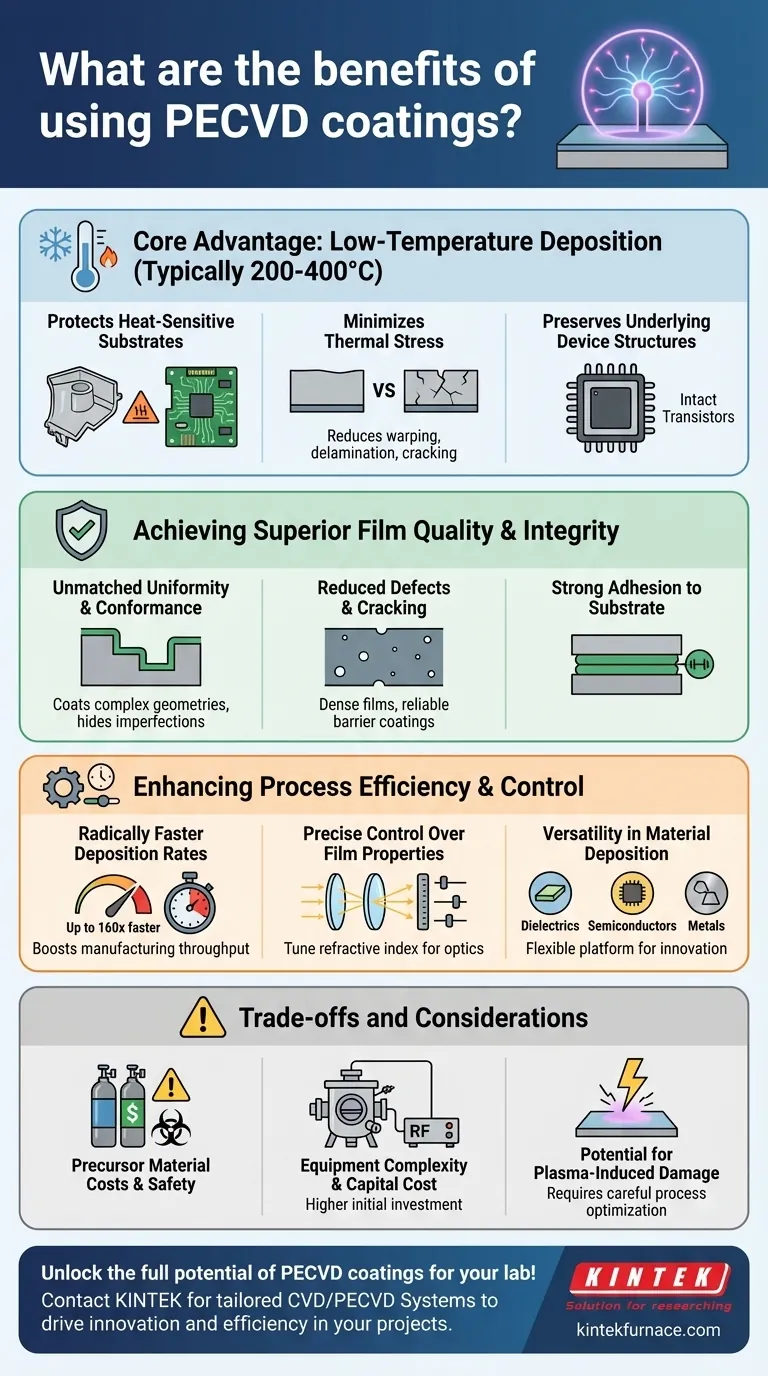

The Core Advantage: Low-Temperature Deposition

The most significant benefit of PECVD is its ability to operate at much lower temperatures (typically 200-400°C) than conventional Chemical Vapor Deposition (CVD), which often requires 600-900°C or higher.

Protecting Heat-Sensitive Substrates

Because it doesn't rely on high heat, PECVD can apply robust coatings to materials like plastics, polymers, and assembled electronic components that would otherwise melt, deform, or degrade.

Minimizing Thermal Stress

High temperatures cause materials to expand and contract, introducing stress that can lead to warping, delamination, or cracking of the substrate or the film itself. The low-temperature nature of PECVD dramatically reduces this risk.

Preserving Underlying Device Structures

In semiconductor manufacturing, delicate transistors and integrated circuits can be damaged by excessive heat. PECVD allows for the deposition of critical dielectric and passivation layers without compromising the integrity and performance of the underlying device.

Achieving Superior Film Quality and Integrity

The plasma-driven process gives engineers exceptional control over the final film, resulting in coatings that are not only protective but also highly uniform and durable.

Unmatched Uniformity and Conformance

PECVD is known for creating films of highly uniform thickness, even over parts with complex geometries and intricate surfaces. This "conformal" coating ensures complete coverage and can even hide minor surface imperfections.

Reduced Defects and Cracking

The resulting films are dense and have fewer pinholes and a significantly reduced likelihood of cracking compared to other methods. This structural integrity is critical for creating reliable barrier coatings.

Strong Adhesion to the Substrate

The energetic plasma environment helps promote excellent adhesion between the coating and the substrate. This ensures the film remains bonded and functional throughout the product's lifespan.

Enhancing Process Efficiency and Control

Beyond quality, PECVD provides significant advantages in manufacturing speed and the ability to custom-engineer film properties for specific applications.

Radically Faster Deposition Rates

By using plasma to accelerate chemical reactions, PECVD can achieve deposition rates that are orders of magnitude faster than conventional CVD. For example, silicon nitride can be deposited up to 160 times faster, directly boosting manufacturing throughput.

Precise Control Over Film Properties

Engineers can meticulously tune film properties by adjusting plasma parameters like gas composition, pressure, and power. This is crucial in optics, where the refractive index of a coating can be precisely controlled to create anti-reflective layers for everything from sunglasses to scientific instruments.

Versatility in Material Deposition

The process is incredibly versatile, capable of depositing a wide range of materials. This includes dielectrics, semiconductors, and even some metals, making it a flexible platform for material innovation.

Understanding the Trade-offs and Considerations

While powerful, PECVD is not a universal solution. An objective evaluation requires acknowledging its specific operational demands.

Precursor Material Costs and Safety

PECVD processes often rely on specialized precursor gases. These materials can be more expensive and may have specific handling and safety requirements compared to precursors used in simpler deposition techniques.

Equipment Complexity and Capital Cost

A PECVD system is a sophisticated piece of equipment involving a vacuum chamber, gas delivery systems, and a radio-frequency (RF) power source to generate the plasma. This complexity results in a higher initial capital investment compared to atmospheric pressure or thermal processes.

Potential for Plasma-Induced Damage

Although the process is low-temperature, the high-energy plasma itself can cause damage to extremely sensitive substrates if not properly managed. Optimizing the process to balance deposition rate with potential surface damage is a key aspect of process engineering.

Making the Right Choice for Your Application

Selecting the right coating technology depends entirely on your primary engineering goal.

- If your primary focus is coating temperature-sensitive materials (like plastics or electronics): PECVD is often the superior or only viable choice due to its low-temperature process.

- If your primary focus is high-throughput manufacturing: The rapid deposition rates of PECVD can offer a significant productivity advantage over conventional CVD.

- If your primary focus is creating highly specialized films (like optical coatings): PECVD provides the fine-tuned control over plasma parameters needed to precisely engineer material properties.

- If your primary focus is maximizing corrosion and chemical resistance: The dense, uniform, and well-adhered films from PECVD provide an exceptional barrier against environmental damage.

Understanding these core benefits allows you to leverage PECVD not just as a coating, but as a strategic tool for material and product innovation.

Summary Table:

| Benefit | Key Features |

|---|---|

| Low-Temperature Deposition | Protects heat-sensitive substrates, minimizes thermal stress, preserves device structures |

| Superior Film Quality | Uniform and conformal coatings, reduced defects, strong adhesion |

| Enhanced Efficiency | Faster deposition rates, precise control over film properties, versatile material deposition |

| Application Suitability | Ideal for electronics, optics, and barrier coatings with high precision |

Unlock the full potential of PECVD coatings for your lab! At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs, whether you're working with heat-sensitive materials or require high-throughput processes. Contact us today to discuss how our tailored PECVD solutions can drive innovation and efficiency in your projects.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment