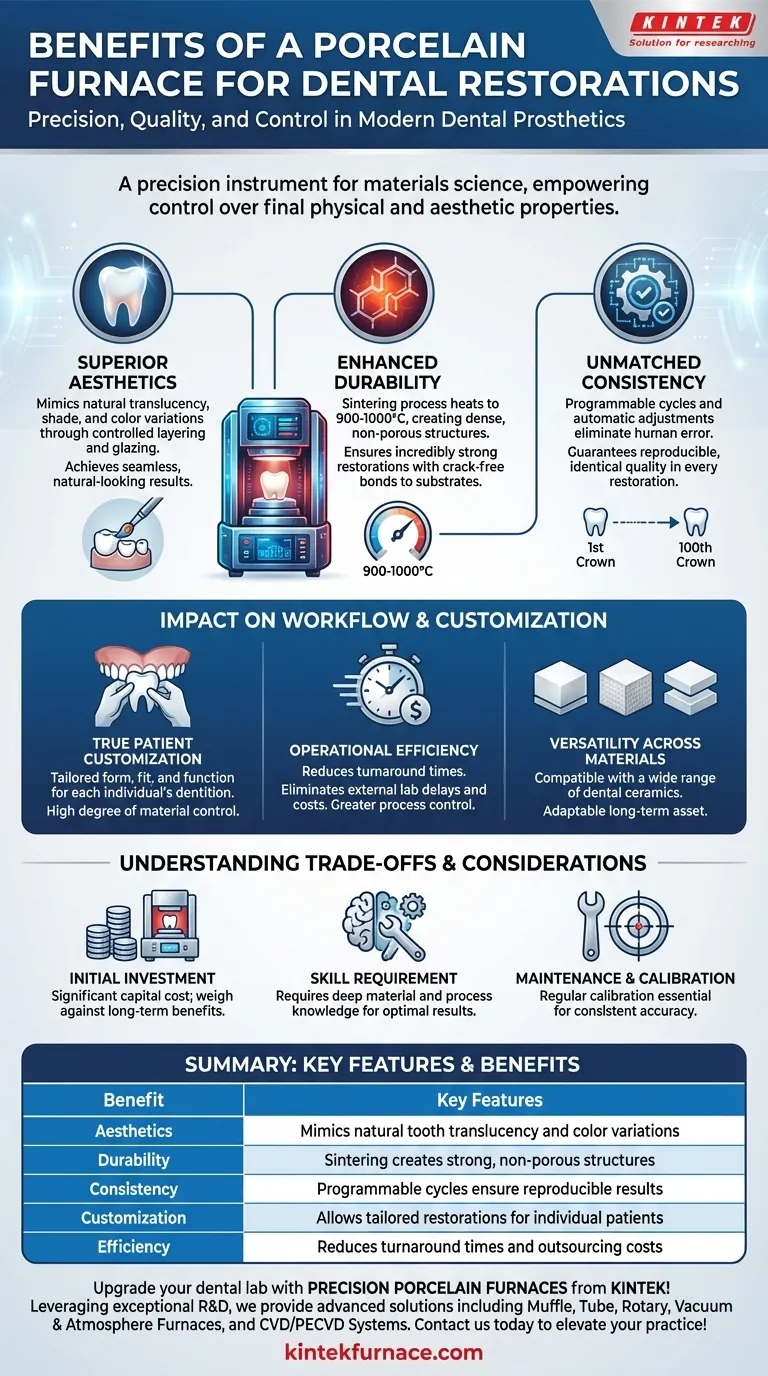

In modern dental prosthetics, precision is the cornerstone of quality. The primary benefits of using a porcelain furnace are the ability to create restorations with superior aesthetics, enhanced durability, and unmatched consistency. A furnace achieves this by giving the technician exact control over the high-temperature firing process, which is critical for transforming ceramic materials into lifelike and resilient dental work.

A porcelain furnace is not merely a heating device; it is a precision instrument for materials science. It empowers the dental professional to control the final physical and aesthetic properties of a restoration, ensuring the outcome is both predictable and of the highest quality.

The Core Mechanisms of a Porcelain Furnace

A furnace's value comes from its ability to precisely manage the ceramic firing process. This control is what translates into tangible benefits for the patient, technician, and dentist.

Achieving Lifelike Aesthetics

The most visible benefit of a furnace is its ability to produce highly aesthetic restorations. The controlled heating cycles allow for the meticulous layering and glazing of porcelain.

This process enables the technician to perfectly mimic the translucency, shade, and subtle color variations of a patient's natural teeth, leading to a seamless and natural-looking result.

Ensuring Long-Term Durability

A furnace creates durability through a process called sintering. It heats the un-fused porcelain particles to temperatures between 900-1000°C, causing them to bond and coalesce into a dense, non-porous structure.

This creates a final restoration that is incredibly strong and capable of withstanding the significant forces of the oral environment. It also ensures a powerful, crack-free bond when fusing porcelain to metal or zirconia substrates.

Guaranteeing Reproducible Consistency

Modern furnaces use pre-set, programmable firing cycles and automatic temperature adjustments. This digital precision eliminates the guesswork and human error common in manual methods.

By removing process variables, the furnace ensures that every restoration is fired under the exact same conditions. This guarantees reproducible results, meaning the 100th crown will be identical in quality to the first.

The Impact on Workflow and Customization

Beyond material quality, a furnace fundamentally improves the operational capabilities of a dental lab or practice.

Enabling True Patient Customization

Because the furnace provides such fine control over the material, it allows for a high degree of customization. Technicians can shape the ceramic while it is malleable to match the unique contours of a patient's dentition.

This goes beyond simple color matching to create a restoration that is tailored in form, fit, and function for each individual, dramatically increasing patient satisfaction.

Driving Operational Efficiency

For dental practices, an in-house furnace can eliminate the time delays and costs associated with outsourcing to an external laboratory. This significantly shortens turnaround times for crowns, veneers, and bridges.

This leads to improved productivity, a higher quality of service, and greater control over the entire restoration process from start to finish.

Versatility Across Materials

Modern porcelain furnaces are not limited to one type of ceramic. They are engineered to be versatile, capable of processing a wide range of dental ceramics available on the market. This makes the furnace a long-term asset that can adapt as new materials are developed.

Understanding the Trade-offs

While powerful, a porcelain furnace is a professional tool with specific operational realities that must be considered.

The Initial Investment

A high-quality, reliable porcelain furnace represents a significant capital investment. The cost must be weighed against the expected volume of work and the financial benefits of in-house production.

The Skill Requirement

A furnace is only as effective as the technician operating it. Achieving exceptional results requires a deep understanding of dental materials, firing temperatures, and specific program cycles. The tool itself does not replace expert knowledge.

Maintenance and Calibration

To maintain the precision that makes it so valuable, a furnace requires regular maintenance and calibration. An uncalibrated furnace will produce inconsistent results, negating its primary benefit and potentially compromising the quality of the restorations.

Making the Right Choice for Your Goal

The decision to integrate a porcelain furnace should be based on your primary objectives.

- If your primary focus is patient satisfaction: A furnace is essential for delivering the highly aesthetic, custom-fitted, and durable restorations that patients demand.

- If your primary focus is lab efficiency: Bringing this capability in-house reduces turnaround times, cuts external lab costs, and gives you direct control over final quality.

- If your primary focus is clinical consistency: The programmable precision of a furnace ensures every restoration meets the exact same high standard, reducing remakes and chair-side adjustments.

Ultimately, investing in and mastering a porcelain furnace empowers you to control the final outcome, transforming your practice or lab into a center for restorative excellence.

Summary Table:

| Benefit | Key Features |

|---|---|

| Aesthetics | Mimics natural tooth translucency and color variations |

| Durability | Sintering creates strong, non-porous structures |

| Consistency | Programmable cycles ensure reproducible results |

| Customization | Allows tailored restorations for individual patients |

| Efficiency | Reduces turnaround times and outsourcing costs |

Upgrade your dental lab with precision porcelain furnaces from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored for dental professionals. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and restoration needs. Enhance your workflow with superior aesthetics, durability, and consistency—contact us today to learn how we can elevate your practice!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations