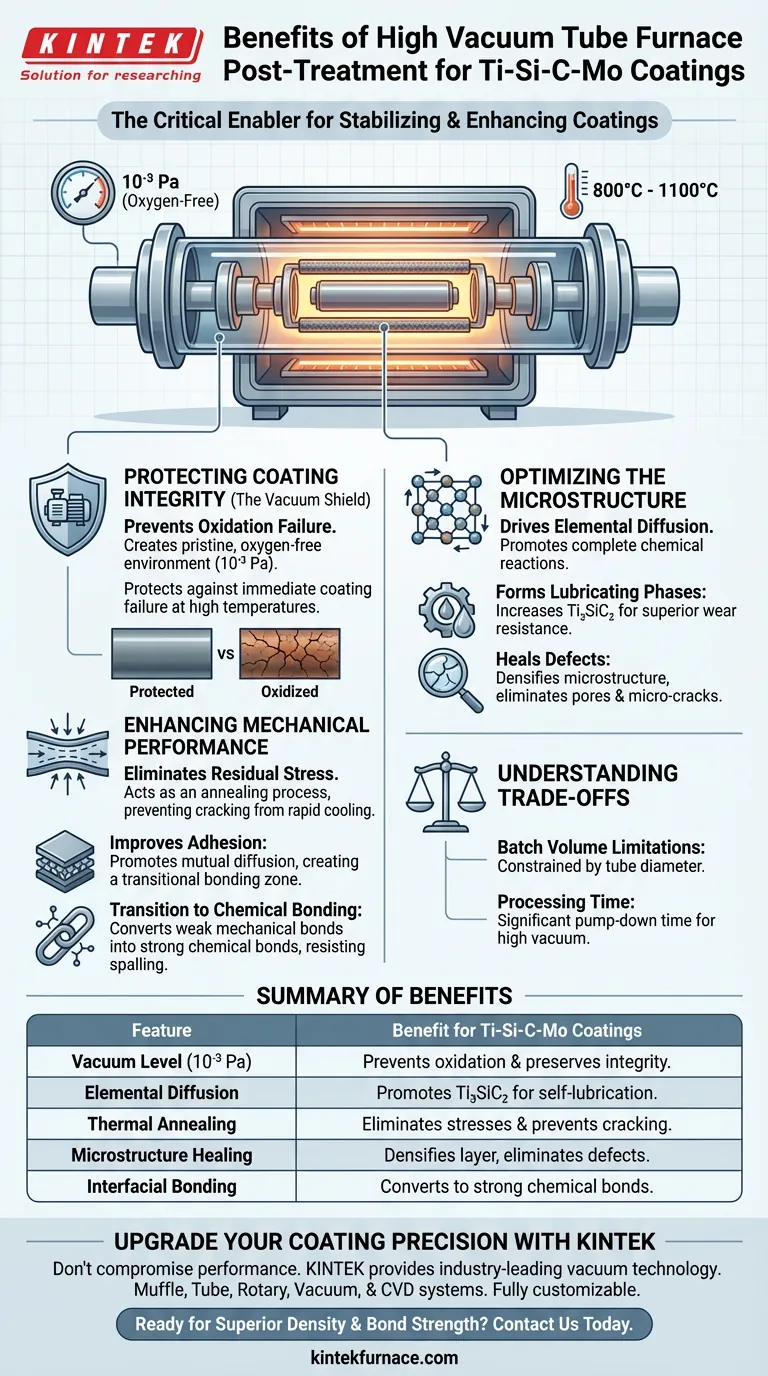

A high vacuum tube furnace is the critical enabler for stabilizing and enhancing Ti-Si-C-Mo coatings. It creates an oxygen-free environment with a vacuum level of approximately $10^{-3}$ Pa, allowing for processing between 800°C and 1100°C without the risk of oxidation failure. This equipment is essential for driving elemental diffusion, healing micro-defects, and synthesizing the specific lubricating phases required for high-performance applications.

By combining precise thermal control with a deep vacuum, you transform a sprayed coating from a mechanically bonded, stressed layer into a dense, chemically bonded system with superior self-lubricating properties.

Protecting Coating Integrity

The Vacuum Shield

The primary benefit is the creation of a pristine, oxygen-free environment ($10^{-3}$ Pa). Ti-Si-C-Mo coatings are highly susceptible to oxidation at elevated temperatures.

Preventing Failure

Without this vacuum protection, the high temperatures required for treatment would cause the coating components to oxidize. This leads to immediate coating failure rather than enhancement.

Optimizing the Microstructure

Driving Elemental Diffusion

The furnace provides a constant temperature field that promotes the movement of atoms within the material. This allows components that did not fully react during the initial spraying process to complete their chemical reactions.

Formation of Lubricating Phases

This diffusion process is specifically tuned to increase the content of $Ti_3SiC_2$. This phase is critical because it acts as a solid lubricant, significantly improving the wear properties of the final coating.

Healing Defects

The high-temperature dwell time allows the microstructure to densify. This process actively heals micro-cracks and eliminates pores, resulting in a more solid and continuous barrier.

Enhancing Mechanical Performance

Eliminating Residual Stress

Sprayed coatings often harbor significant internal tension due to rapid cooling during application. The vacuum heat treatment acts as an annealing process, effectively eliminating residual stresses that could otherwise lead to cracking.

Improving Adhesion

Beyond the coating itself, the treatment affects the interface between the coating and the substrate. The heat promotes mutual diffusion, creating a transitional bonding zone.

Transition to Chemical Bonding

This diffusion converts the connection from a weak mechanical bond into a strong chemical bond. This significantly increases the coating's resistance to spalling (flaking off) under operational stress.

Understanding the Trade-offs

Batch Volume Limitations

Tube furnaces are generally constrained by the diameter of the tube. This limits the size and quantity of components you can treat simultaneously compared to larger box furnaces.

Processing Time

Achieving a high vacuum of $10^{-3}$ Pa requires significant pump-down time before heating can begin. This adds to the overall cycle time compared to atmospheric or inert gas processes.

Making the Right Choice for Your Goal

- If your primary focus is Wear Resistance: Ensure your cycle time is sufficient to maximize the formation of the $Ti_3SiC_2$ lubricating phase.

- If your primary focus is Durability/Adhesion: Prioritize temperatures that favor deep elemental diffusion to convert mechanical bonds into chemical bonds.

The high vacuum tube furnace is not just a heater; it is a reactor that fundamentally alters the chemistry and physics of your coating to ensure longevity.

Summary Table:

| Feature | Benefit for Ti-Si-C-Mo Coatings |

|---|---|

| Vacuum Level ($10^{-3}$ Pa) | Prevents oxidation failure and preserves material integrity. |

| Elemental Diffusion | Promotes $Ti_3SiC_2$ formation for superior self-lubrication. |

| Thermal Annealing | Eliminates residual stresses and prevents cracking. |

| Microstructure Healing | Densifies the layer by eliminating pores and micro-defects. |

| Interfacial Bonding | Converts mechanical bonds into strong chemical bonds. |

Upgrade Your Coating Precision with KINTEK

Don't let oxidation or residual stress compromise your material performance. KINTEK provides industry-leading vacuum technology designed to transform sprayed layers into high-performance systems. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique lab requirements.

Ready to achieve superior coating density and bond strength? Contact us today to discuss how our high-temperature furnace solutions can solve your specific engineering challenges.

Visual Guide

References

- Jining He, Jiawei Fan. High-Temperature Heat Treatment of Plasma Sprayed Ti–Si–C–Mo Coatings. DOI: 10.3390/coatings14010109

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing