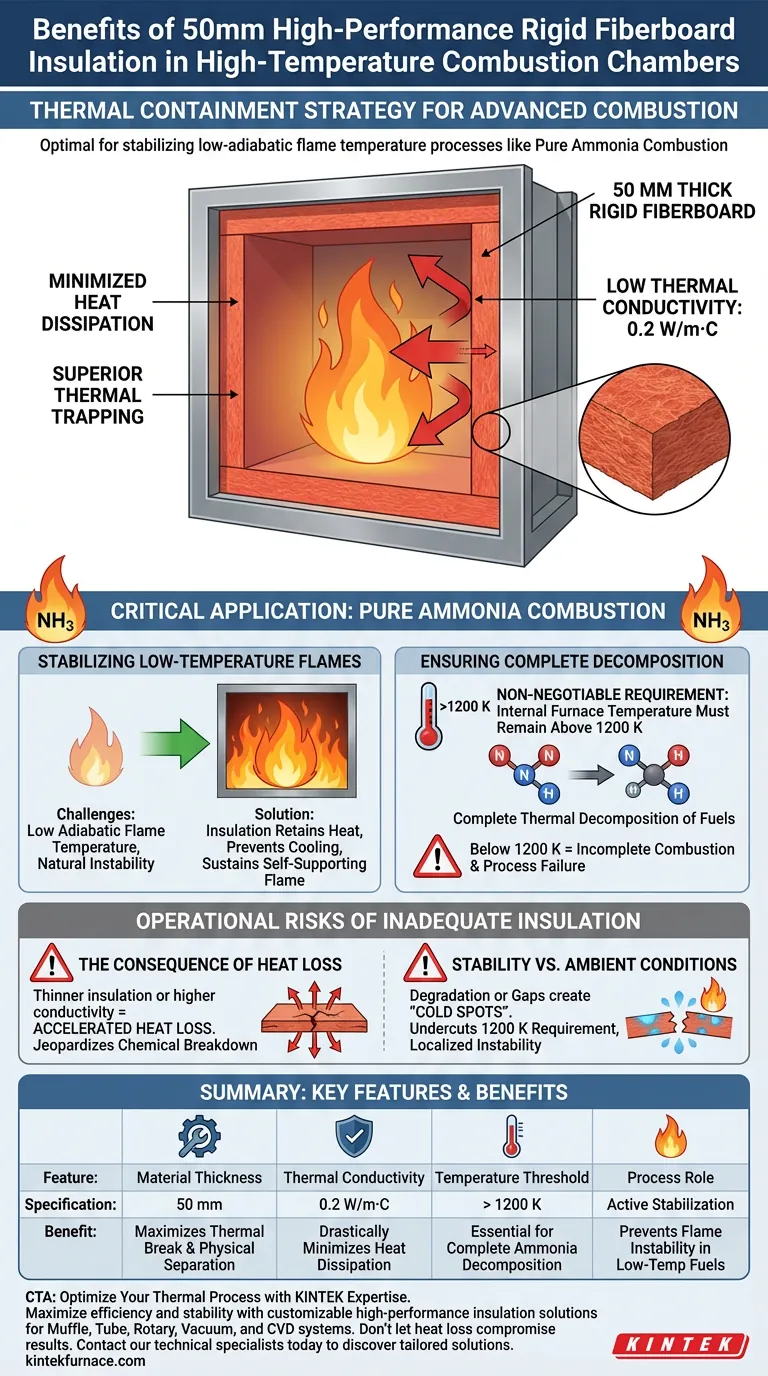

The utilization of 50 mm thick high-performance rigid fiberboard serves as a vital thermal containment strategy in advanced combustion chambers. Its primary benefit is providing an exceptionally low thermal conductivity of 0.2 W/m·C, which drastically minimizes heat dissipation into the surrounding environment. By effectively trapping thermal energy, this insulation lining stabilizes combustion processes that are naturally prone to instability due to low adiabatic flame temperatures.

The core value of this insulation configuration is its ability to sustain internal furnace temperatures above the critical 1200 K threshold. This is a non-negotiable requirement for the complete thermal decomposition of fuels with low flame temperatures, such as pure ammonia.

The Mechanics of Thermal Stability

Minimizing Thermal Conductivity

The defining characteristic of this fiberboard is its thermal conductivity of 0.2 W/m·C.

In high-temperature engineering, this low value acts as a formidable barrier against heat transfer. It prevents the rapid equalization of temperature between the furnace interior and the external environment.

The Role of Thickness

While the material properties are fundamental, the 50 mm thickness is equally critical to the system's performance.

This specific thickness ensures sufficient physical separation to maximize the material's insulating potential. It creates a robust thermal break that significantly reduces the rate of heat loss during operation.

Critical Application: Pure Ammonia Combustion

Stabilizing Low-Temperature Flames

Certain fuels, such as pure ammonia, are characterized by low adiabatic flame temperatures.

Unlike standard hydrocarbons, these fuels struggle to sustain a self-supporting flame without assistance. The insulation compensates for this by retaining the heat generated, preventing the combustion environment from cooling effectively.

Ensuring Complete Decomposition

To achieve complete thermal decomposition of ammonia molecules, the environment must maintain a specific thermal floor.

The 50 mm fiberboard lining ensures the internal furnace temperature remains strictly above 1200 K. Without this thermal retention, the temperature would drop below this threshold, leading to incomplete combustion and potential process failure.

Understanding the Operational Risks

The Consequence of Heat Loss

The primary pitfall in these systems is under-estimating the sensitivity of the fuel to temperature drops.

If the insulation is thinner than 50 mm or possesses higher conductivity, heat loss will accelerate. In the context of ammonia combustion, this does not simply lower efficiency; it jeopardizes the chemical breakdown of the fuel entirely.

Stability vs. Ambient Conditions

Reliance on high-performance insulation means the system is heavily dependent on the integrity of the lining.

Any degradation in the fiberboard or gaps in the installation will create "cold spots." These breaches effectively undercut the 1200 K requirement, leading to localized instability within the combustion chamber.

Making the Right Choice for Your Project

High-performance rigid fiberboard is not merely a passive liner; it is an active component in process stabilization.

- If your primary focus is Pure Ammonia Combustion: You must ensure the lining maintains temperatures >1200 K to guarantee complete molecular decomposition.

- If your primary focus is Energy Efficiency: Prioritize the 50 mm thickness to minimize heat loss to the environment and maximize thermal retention.

By selecting the correct insulation specifications, you transform thermal management from a safety feature into a process enabler.

Summary Table:

| Feature | Specification/Impact | Benefit |

|---|---|---|

| Material Thickness | 50 mm | Maximizes thermal break and physical separation |

| Thermal Conductivity | 0.2 W/m·C | Drastically minimizes heat dissipation |

| Temperature Threshold | > 1200 K | Essential for complete ammonia decomposition |

| Process Role | Active Stabilization | Prevents flame instability in low-temp fuels |

Optimize Your Thermal Process with KINTEK Expertise

Maximize your laboratory's efficiency and process stability with high-performance insulation solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other high-temperature lab furnaces—all fully customizable to meet your unique thermal decomposition and combustion needs.

Don't let heat loss compromise your results. Contact our technical specialists today to discover how our tailored high-temperature systems can ensure the precision and stability your research demands.

Visual Guide

References

- Lizhen Qin, Dong-Hoon Shin. Swirling Flameless Combustion of Pure Ammonia Fuel. DOI: 10.3390/en18123104

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the characteristics of aluminum for heating applications? Unlock Efficient Heat Transfer Solutions

- How is a silicon carbide heating element manufactured? Discover the High-Temperature Process for Durable Heaters

- What are the characteristics of molybdenum disilicide heating elements? Unlock High-Temp Performance

- What are the advantages of Nickel-Chrome (NiCr) alloys for heating elements? Discover High-Temp Durability & Efficiency

- What are the operating temperature limits for 'one piece' and 'three piece' SiC resistors in air or inert atmospheres? Ensure Longevity and Performance

- How can the SiO2 protective layer on MoSi2 heating elements be regenerated if it bursts off? Restore Element Performance with Expert Tips

- What is the function of ceramic washers in SWCNT-BNNT synthesis? Elevate Your Nanomaterial Precision

- What are the advantages of ceramic materials like alumina and silicon nitride in heating elements? Achieve Superior Heat Treatment Efficiency