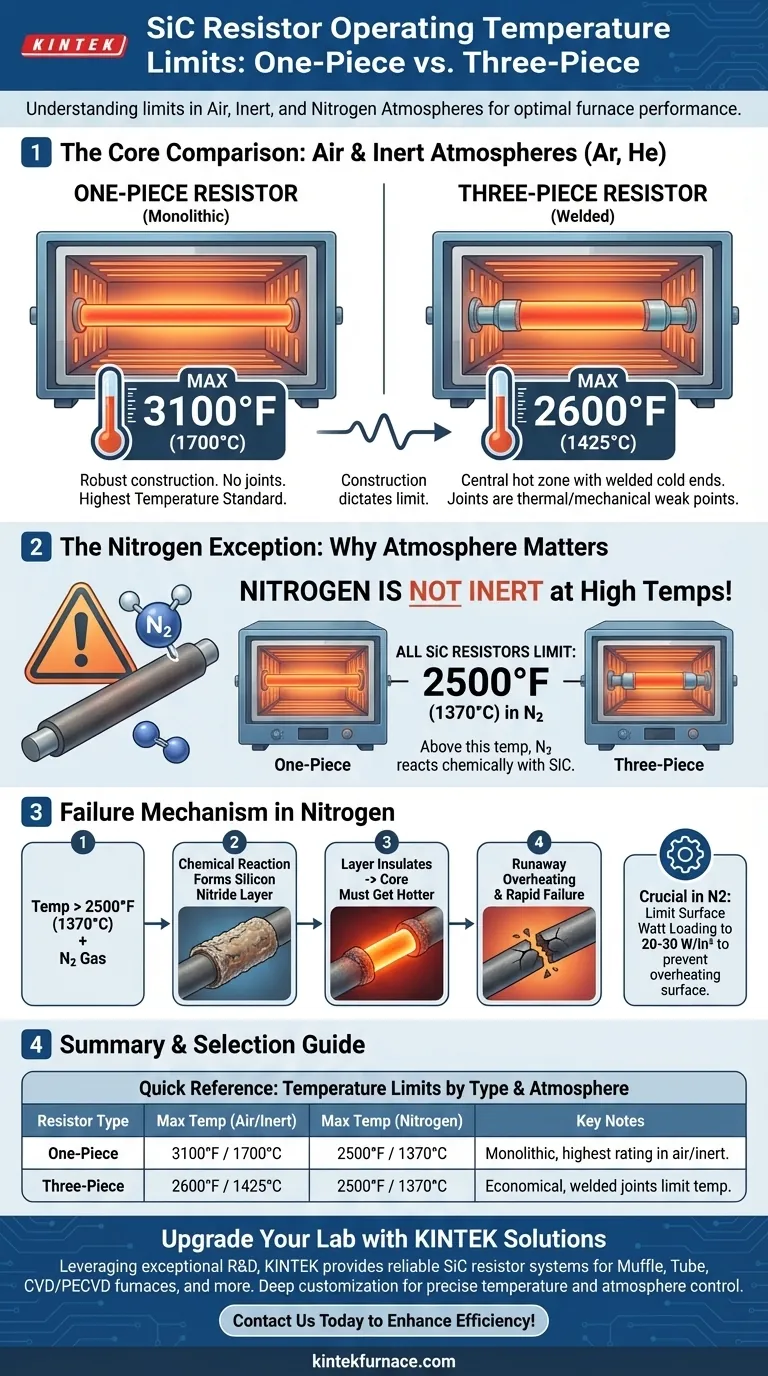

In an air or inert atmosphere, one-piece silicon carbide (SiC) resistors can be operated at furnace control temperatures up to 3100°F (1700°C), while three-piece designs are limited to 2600°F (1425°C). These limits are not arbitrary; they are dictated by the resistor's physical construction and its chemical interaction with the surrounding environment.

The maximum operating temperature of a SiC heating element is determined by two factors: its physical construction ('one-piece' vs. 'three-piece') and the chemical reactivity of the furnace atmosphere. Exceeding these limits or using an incompatible gas can lead to rapid degradation and failure.

Understanding Temperature Limits by Resistor Type

The fundamental difference in temperature rating comes down to the manufacturing and design of the resistor itself.

One-Piece Resistors: The High-Temperature Standard

A 'one-piece' resistor is a monolithic element, meaning it is formed from a single, continuous piece of silicon carbide. This robust construction eliminates joints or welds, which are typical points of mechanical and thermal failure.

This design allows for the highest possible operating temperature. In a suitable atmosphere, these resistors can reliably reach furnace temperatures of 3100°F (1700°C).

Three-Piece Resistors: The General-Purpose Workhorse

A 'three-piece' resistor consists of a central hot zone welded to two colder terminal ends. While highly effective, the welded joints between these sections introduce a thermal and mechanical weak point compared to a monolithic design.

These joints are the primary reason for the lower temperature rating. Consequently, three-piece elements are limited to a maximum furnace temperature of 2600°F (1425°C).

The Critical Role of Furnace Atmosphere

The temperature a SiC resistor can withstand is directly tied to the gas surrounding it. A seemingly inert gas can become highly reactive at extreme temperatures, damaging the element.

Air and Inert Gases (Argon, Helium)

The maximum temperature ratings for both one-piece and three-piece resistors are specified for operation in either air or a true inert atmosphere like argon or helium. These environments are the least reactive with silicon carbide at high temperatures.

The Nitrogen Exception

Nitrogen is often used as a cost-effective alternative to argon, but it is not truly inert at the operating temperatures of SiC elements. In a nitrogen atmosphere, all SiC resistors are limited to a much lower temperature of 2500°F (1370°C).

Surface Watt Loading in Nitrogen

When using nitrogen, you must also limit the surface watt loading of the resistor to a maximum of 20 to 30 watts per square inch. This prevents the surface of the element from getting significantly hotter than the surrounding furnace atmosphere.

Understanding the Trade-offs and Failure Modes

Selecting the right element requires understanding why these limits exist and what happens when they are exceeded.

The Risk of Chemical Reaction

The primary failure mode in a nitrogen atmosphere is a chemical reaction. At temperatures above 2500°F (1370°C), the nitrogen reacts with the silicon carbide surface.

This reaction forms a thin layer of silicon nitride.

Thermal Insulation and Failure

This silicon nitride layer acts as a thermal insulator. To maintain its required power output, the resistor must get hotter internally to push heat through this new insulating layer.

This leads to a runaway effect where the element's core temperature rises uncontrollably, causing rapid degradation and premature failure.

Construction vs. Performance

The trade-off between resistor types is clear. One-piece designs offer superior temperature performance due to their monolithic construction. Three-piece designs, while limited to lower temperatures, are often a sufficient and more economical choice for many standard furnace applications.

Making the Right Choice for Your Application

Your process requirements will dictate the correct choice of resistor and operating parameters.

- If your primary focus is maximum temperature in air or argon: The one-piece SiC resistor is your only option, rated for up to 3100°F (1700°C).

- If your process runs below 2600°F in air or argon: A three-piece resistor is a viable and often more cost-effective choice.

- If you must operate in a nitrogen atmosphere: You are strictly limited to 2500°F (1370°C) and must carefully manage surface watt loading to prevent chemical degradation.

Understanding these environmental and construction limits is the key to ensuring both the safety and longevity of your high-temperature system.

Summary Table:

| Resistor Type | Max Temp in Air/Inert (°F) | Max Temp in Air/Inert (°C) | Max Temp in Nitrogen (°F) | Max Temp in Nitrogen (°C) | Key Notes |

|---|---|---|---|---|---|

| One-Piece | 3100°F | 1700°C | 2500°F | 1370°C | Monolithic design, no joints, highest temp rating |

| Three-Piece | 2600°F | 1425°C | 2500°F | 1370°C | Welded joints, economical for lower temps |

Upgrade your lab's high-temperature capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable SiC resistor systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, from temperature control to atmosphere compatibility. Don't let resistor limits hold you back—contact us today to discuss how our solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs