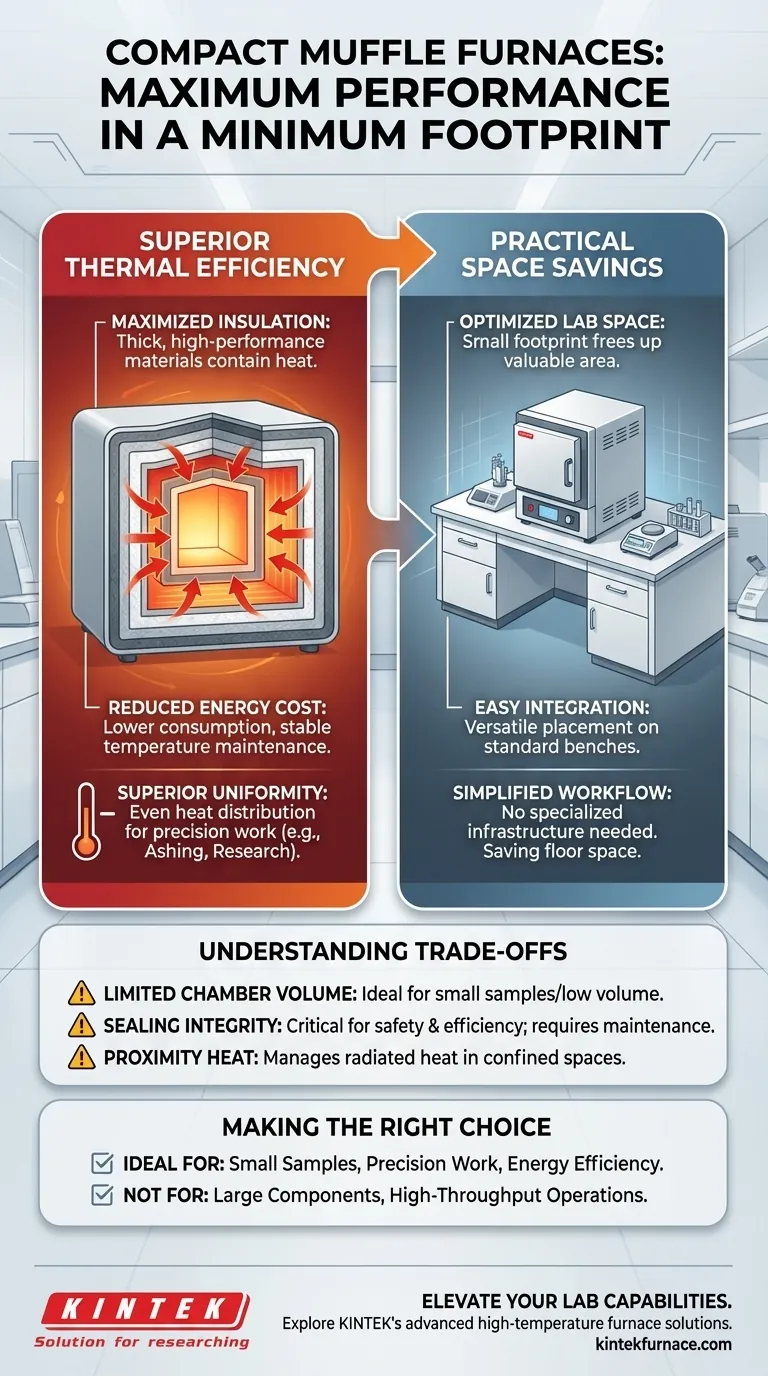

At its core, the compact design of a muffle furnace delivers two primary benefits: exceptional thermal efficiency and practical space savings. This design is not merely about making the equipment smaller; it is a deliberate engineering choice that allows the furnace to achieve and maintain extreme temperatures while minimizing energy consumption and fitting seamlessly into modern laboratory environments.

The compact nature of a muffle furnace is a direct consequence of its primary function. By using thick insulation to create a small, tightly sealed chamber, the design minimizes the surface area for heat to escape, directly enabling the stable, uniform, and high-temperature environments required for precision work.

The Principle of High Thermal Efficiency

A muffle furnace's small size is intrinsically linked to its performance. The design prioritizes the containment of heat above all else, and a compact form is the most effective way to achieve this.

Maximizing Insulation, Minimizing Footprint

The design philosophy is simple: surround a small internal chamber with thick, high-performance insulation. This minimizes the overall external footprint while maximizing the furnace's ability to prevent heat from escaping.

This dense insulation is why a furnace with a small internal capacity can feel so substantial. The bulk is not empty space; it is a critical component for thermal containment.

Reducing Heat Loss and Energy Costs

A smaller external surface area directly translates to less area for heat dissipation. This means the furnace's heating elements do not have to work as hard or as often to maintain a set temperature.

The result is significantly lower energy consumption, especially during long heat-treating cycles, making the furnace more cost-effective to operate. The meticulous sealing of the furnace door—often with multi-layer ceramic and silicone seals—is critical to preventing heat leaks and maintaining this efficiency.

Achieving Superior Temperature Uniformity

When heat is effectively contained, it distributes more evenly throughout the chamber. A compact, well-insulated muffle furnace provides superior temperature uniformity, which is non-negotiable for sensitive applications.

Processes like ashing samples, materials research, and specific heat treatments depend on every part of the sample experiencing the exact same temperature. The compact design is fundamental to delivering this precision.

Practical Advantages in the Workspace

Beyond thermal performance, the physical dimensions of a compact muffle furnace offer clear logistical benefits, especially in environments where space is a premium.

Optimizing Valuable Lab Space

Laboratories and research facilities are often crowded with essential equipment. A muffle furnace's small footprint allows it to be placed on a standard workbench, freeing up valuable floor space for other apparatus.

Enhancing Versatility and Placement

The compact and self-contained nature of these furnaces makes them easy to install and integrate into an existing workflow. They do not typically require specialized infrastructure, adding to their versatility.

Understanding the Trade-offs

While highly beneficial, the compact design brings inherent limitations that you must consider. Objectivity requires acknowledging what the design is not optimized for.

Limited Chamber Volume

The most obvious trade-off is internal capacity. A compact furnace is, by definition, designed for small samples or low-volume batch processing. It is unsuitable for treating large components or running high-throughput operations.

The Importance of Sealing Integrity

The design's efficiency is heavily dependent on the integrity of its seals. The multi-point locks and advanced hinge mechanisms are there for a reason. If these components wear out or fail, the furnace's thermal performance and safety will be compromised. Regular inspection and maintenance are essential.

Proximity Heat Management

Even with excellent insulation, a device operating at over 1000°C will radiate heat into its immediate surroundings. In a very small or poorly ventilated space, this ambient heat gain can become a factor for nearby equipment or personnel.

Making the Right Choice for Your Application

Ultimately, the choice depends entirely on your specific goals. Understanding the engineering behind the compact design allows you to align the tool with the task.

- If your primary focus is processing small samples with high thermal precision: The compact design is ideal, as it ensures the energy efficiency and temperature uniformity critical for repeatable results.

- If your primary focus is high-throughput or treating large components: A compact muffle furnace will likely be a bottleneck, and a larger industrial furnace or a different heating technology should be considered.

By recognizing that its compact size is a feature engineered for performance, you can confidently determine if a muffle furnace is the right solution for your work.

Summary Table:

| Benefit | Key Features |

|---|---|

| Thermal Efficiency | Thick insulation, reduced heat loss, superior temperature uniformity |

| Space Savings | Small footprint, easy installation, versatile placement |

| Energy Cost Reduction | Lower consumption, stable temperature maintenance |

| Application Suitability | Ideal for small samples, precision work; limited for high-throughput |

Ready to elevate your laboratory's capabilities with a compact muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to precisely meet your unique experimental needs. Contact us today to discuss how our compact designs can enhance your efficiency and save space!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength