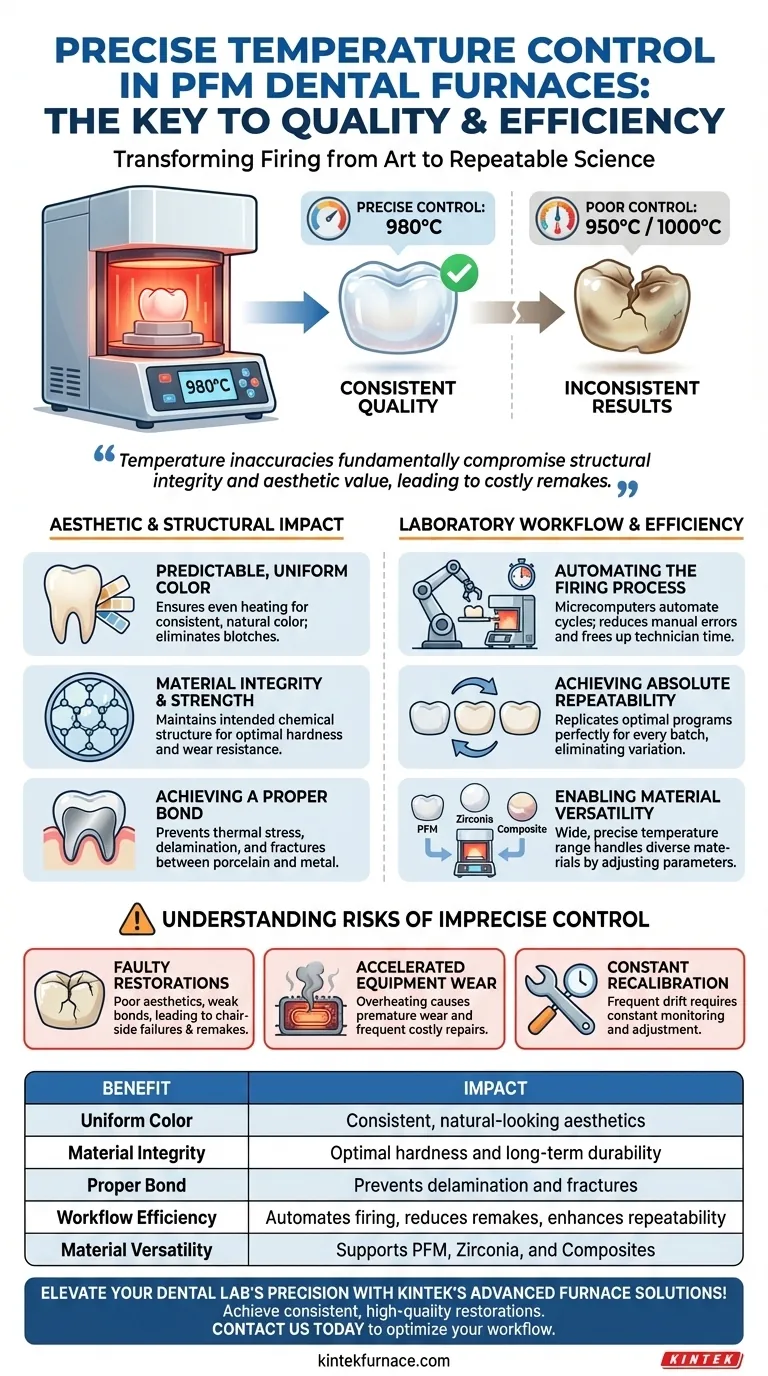

In porcelain-fused-to-metal (PFM) fabrication, precise temperature control is not a luxury feature—it is the core determinant of quality, consistency, and efficiency. A furnace with exact temperature management ensures that every restoration achieves its intended color, strength, and durability. This precision transforms the firing process from an unpredictable art into a repeatable science.

The core function of a dental furnace is not merely to heat porcelain, but to perfectly manage a complex chemical and physical transformation. Temperature inaccuracies don't just cause minor flaws; they fundamentally compromise the structural integrity and aesthetic value of the final dental restoration, leading to costly remakes and inconsistent results.

The Impact on Aesthetic and Structural Outcomes

The final quality of a PFM crown is forged in the furnace. Even minor temperature deviations can have an outsized impact on the final product that reaches the dentist and patient.

Ensuring Predictable, Uniform Color

The aesthetic success of a restoration hinges on its ability to perfectly match the patient's natural teeth. Precise temperature control ensures the porcelain powder is heated evenly throughout the sintering process.

This uniformity is critical for achieving a consistent, homogenous color without blotches or discolored areas, guaranteeing a predictable and natural-looking result every time.

Guaranteeing Material Integrity and Strength

Sintering is a delicate process that defines the final physical properties of the porcelain. Exact temperature regulation maintains the material's intended chemical and physical structure.

This results in an ideal sintering state, producing a restoration with stable hardness and optimal wear resistance, ensuring its long-term clinical success and durability.

Achieving a Proper Bond

Imprecise firing can compromise the crucial bond between the porcelain and the underlying metal framework. Proper temperature control prevents thermal stress that can lead to delamination or fractures.

This ensures the restoration functions as a single, durable unit, capable of withstanding the forces of mastication over many years.

The Effect on Laboratory Workflow and Efficiency

A modern dental furnace is a production tool. Its ability to accurately control temperature directly influences a dental lab's productivity, profitability, and reputation.

Automating the Firing Process

Advanced furnaces use microcomputer systems to automate the entire firing cycle, from the initial heating rate to the holding time and final cooling phase.

This automation frees up technician time, reduces the potential for manual oversight errors, and allows for a more streamlined and efficient workflow.

Achieving Absolute Repeatability

The most significant workflow benefit is process repeatability. Once an optimal firing program for a specific porcelain is established, a furnace with precise control can replicate it perfectly for every subsequent unit.

This consistency eliminates variation between batches, improves overall quality stability, and dramatically reduces the need for costly and time-consuming remakes.

Enabling Material Versatility

The dental industry is constantly evolving, with new materials being introduced. A furnace with a wide, precisely controlled temperature range is a future-proof investment.

It allows a lab to work with a diverse array of materials, from traditional porcelains to zirconia ceramics and composite resins, simply by adjusting the firing parameters to meet each material's unique requirements.

Understanding the Risks of Imprecise Control

The consequences of poor temperature control extend beyond a single failed crown. They can negatively impact the entire laboratory operation, from material costs to equipment lifespan.

The High Cost of Faulty Restorations

When a furnace fails to hold a stable and accurate temperature, the resulting restorations are often compromised.

This can manifest as poor aesthetics, insufficient strength, or a weak bond, leading directly to chairside failures, remakes, and a loss of trust from your dental clients.

Accelerated Equipment Wear

Inaccurate temperature management can damage the furnace itself. Overheating or fluctuating temperatures cause premature wear and soiling of critical components like heating wires and insulation.

This leads to more frequent and costly repairs, as well as equipment downtime that halts production.

The Need for Constant Recalibration

While all furnaces require periodic calibration, those with poor internal controls will drift from their set points more frequently. This requires constant monitoring and adjustment to prevent faulty firings.

A high-quality furnace maintains its calibration for longer, providing more reliable and trustworthy performance day after day.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its capabilities to your laboratory's primary objectives.

- If your primary focus is high-end aesthetic restorations: Prioritize a furnace with documented temperature uniformity and highly customizable, user-definable firing programs.

- If your primary focus is high-volume production: Look for robust automation, a large library of pre-set programs, and fast heating and cooling cycles to maximize throughput.

- If your primary focus is material versatility: Ensure the furnace offers a wide, stable temperature range and the flexibility to handle PFM, all-ceramics, and other advanced materials.

Ultimately, investing in precise temperature control is an investment in predictable outcomes and the reputation of your laboratory.

Summary Table:

| Benefit | Impact |

|---|---|

| Uniform Color | Ensures consistent, natural-looking aesthetics without blotches |

| Material Integrity | Provides optimal hardness and wear resistance for long-term durability |

| Proper Bond | Prevents delamination and fractures for a strong metal-porcelain bond |

| Workflow Efficiency | Automates firing, reduces remakes, and enhances repeatability |

| Material Versatility | Supports diverse materials like PFM, zirconia, and composites |

Elevate your dental lab's precision and productivity with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs. Achieve consistent, high-quality restorations with reliable temperature control—contact us today to discuss how we can optimize your workflow and deliver superior results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab