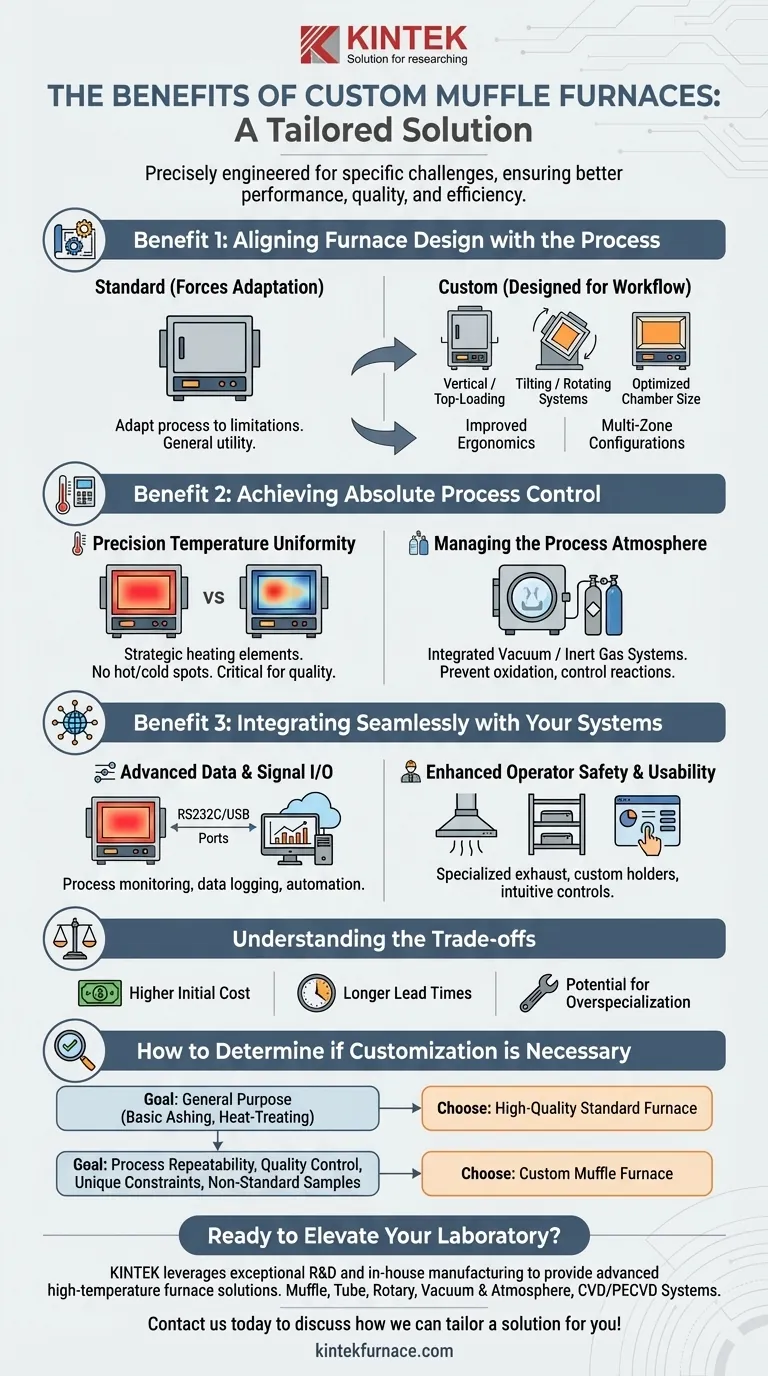

The primary benefit of a custom muffle furnace is its ability to be precisely engineered to meet your exact process requirements. Unlike standard, off-the-shelf models, a custom furnace is built to solve a specific challenge, ensuring better performance, higher product quality, and greater efficiency for unique or demanding applications in materials research and production.

While standard furnaces offer general utility, customization transforms the furnace from a simple piece of equipment into a tailored solution. This approach is not about adding features for their own sake; it's about aligning the furnace's core design, atmosphere, and controls with a specific scientific or manufacturing goal.

Benefit 1: Aligning Furnace Design with the Process

A standard furnace forces you to adapt your process to its limitations. A custom furnace is designed around your specific workflow, sample characteristics, and physical space.

Optimizing Orientation and Access

Many standard furnaces are front-loading horizontal boxes. Customization allows for designs that better suit your process, such as vertical models for top-loading, or even tilting and rotating systems for applications requiring uniform exposure or material mixing at high temperatures.

This physical alignment can significantly improve ergonomics, reduce handling errors, and enable processes that would be impossible in a standard chamber.

Matching Sample Size and Throughput

Customization allows the internal chamber dimensions to be built to your exact specifications. This ensures you are not paying to heat empty space, improving energy efficiency.

Furthermore, for production environments, multi-zone configurations can be designed to create specific temperature profiles along the length of the furnace, optimizing throughput and process consistency for continuous or batch work.

Benefit 2: Achieving Absolute Process Control

The most critical benefits of customization often lie in achieving a level of process control that standard models cannot provide. This is essential for sensitive materials and applications where repeatability is non-negotiable.

Precision Temperature Uniformity

While modern furnaces offer good temperature control, custom units can take this to a higher level. By strategically placing high-quality heating elements and using advanced control systems, a custom furnace can provide superior temperature uniformity across the entire workpiece.

This eliminates hot or cold spots, ensuring that every part of your sample receives the exact same thermal treatment, which is critical for materials science and quality control.

Managing the Process Atmosphere

Many advanced processes require a controlled atmosphere to prevent oxidation or introduce specific chemical reactions. Custom furnaces can be equipped with integrated vacuum packages or inert gas systems (like Nitrogen or Argon) complete with flow meters and controllers.

This allows you to completely isolate the material from combustion contaminants or reactive gases like oxygen, a fundamental requirement for applications in electronics, metallurgy, and advanced materials research.

Benefit 3: Integrating Seamlessly with Your Systems

A modern laboratory or production facility relies on data and automation. Customization enables the furnace to become an integrated part of this ecosystem rather than a standalone island.

Advanced Data and Signal I/O

Custom furnaces can be built with a suite of output terminals for process monitoring. This includes temperature and alarm outputs, as well as RS232C or other communication ports for logging data directly to a central system.

This level of integration is essential for process validation, quality assurance documentation, and automated control loops.

Enhanced Operator Safety and Usability

Beyond performance, customization can address specific safety and usability needs. This includes specialized exhaust systems to safely vent fumes, custom sample holders or racks, and intuitive control interfaces tailored to your team's workflow.

Understanding the Trade-offs

Objectivity requires acknowledging that a custom solution is not always the right choice. You must consider the clear trade-offs before committing.

Higher Initial Cost

A furnace designed and built for a single purpose will inherently have a higher upfront cost than a mass-produced, standard model. This investment must be justified by a clear return in quality, efficiency, or research capability.

Longer Lead Times

The process of consultation, design, fabrication, and testing for a custom unit takes significantly more time than ordering a stock item. Project timelines must account for this extended lead time.

Potential for Overspecialization

A furnace perfectly tailored for one process may be less suitable for another. If your research or production needs are expected to change frequently, a more flexible, general-purpose furnace might be a more strategic long-term investment.

How to Determine if Customization is Necessary

Use your primary goal to guide your decision between a standard and custom muffle furnace.

- If your primary focus is general-purpose lab work like basic ashing or simple heat-treating: A high-quality standard furnace is almost always the most cost-effective and practical choice.

- If your primary focus is process repeatability and quality control for a specific product: Customization of temperature controls, atmosphere management, and data logging is a critical investment.

- If you have unique physical constraints or deal with non-standard sample sizes: A furnace with custom dimensions, orientation, or material handling systems will deliver significant efficiency and safety gains.

Choosing the right furnace is an investment in the accuracy and efficiency of your future work.

Summary Table:

| Benefit | Key Features |

|---|---|

| Aligning Furnace Design with Process | Custom orientation, optimized chamber size, multi-zone configurations |

| Achieving Absolute Process Control | Superior temperature uniformity, controlled atmosphere systems |

| Integrating Seamlessly with Systems | Advanced data I/O, enhanced safety features |

| Trade-offs | Higher initial cost, longer lead times, potential for overspecialization |

Ready to elevate your laboratory's capabilities with a custom muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering enhanced performance, efficiency, and quality for materials research and production. Don't settle for standard equipment—contact us today to discuss how we can tailor a solution for you!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals