Beyond a simple oven, a dental sintering furnace is the central pillar of your lab's restorative quality and operational efficiency. A carefully selected furnace delivers clinically superior restorations that fit precisely and withstand long-term use. This choice directly translates into enhanced lab productivity, reduced labor costs, and a stronger bottom line by optimizing material usage and shortening production cycles.

Your sintering furnace isn't just a piece of equipment; it's the core engine that determines the final strength, fit, and aesthetics of your ceramic restorations. The selection process is about matching the furnace's technical capabilities directly to your lab's specific production goals and material choices.

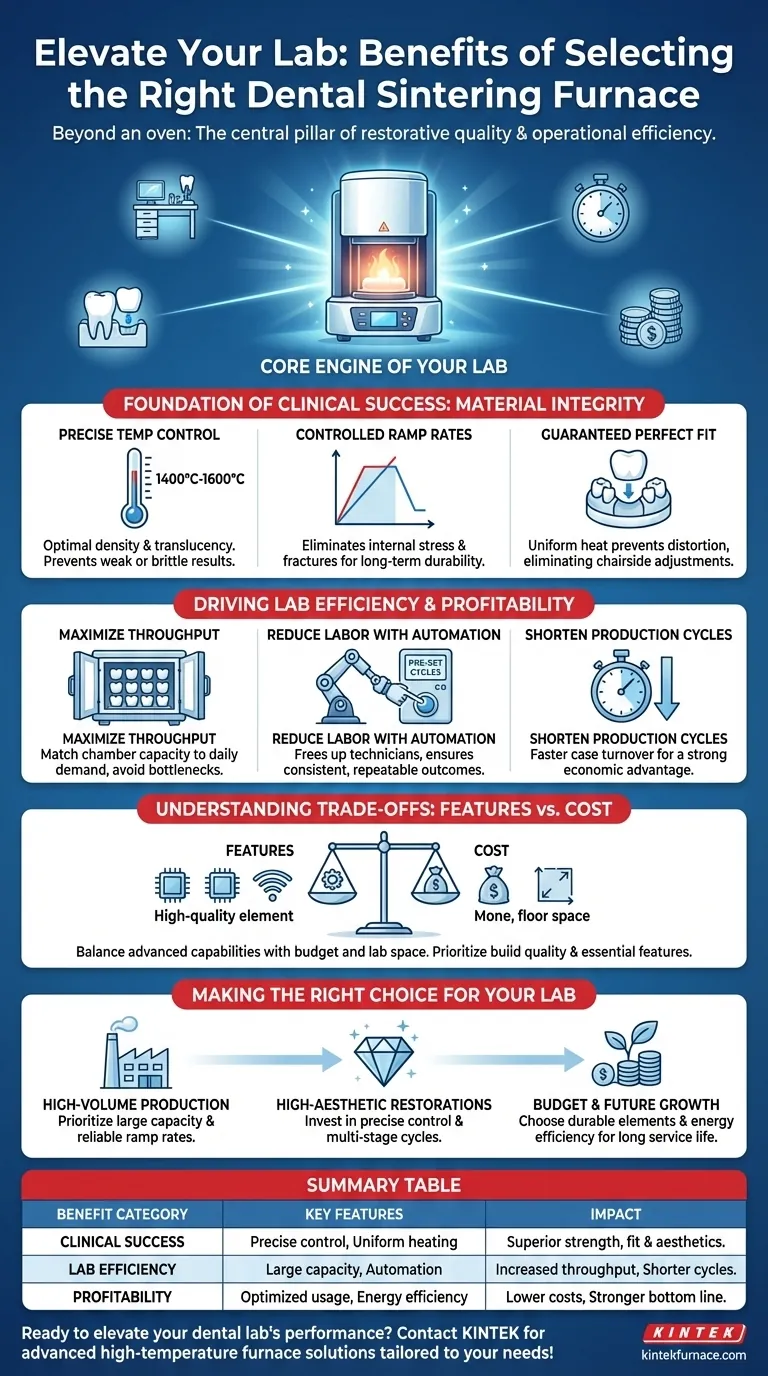

The Foundation of Clinical Success: Material Integrity

The primary benefit of a premium furnace is its ability to produce restorations that meet the highest clinical standards. This is achieved through precise control over the complex sintering process.

Achieving Precise Temperature Control

The final physical properties of materials like zirconia are determined by achieving and holding exact temperatures, often between 1400°C and 1600°C.

Inadequate temperature control leads to under-sintered restorations that are weak and opaque, or over-sintered ones that are distorted and brittle. Precise control ensures optimal density and translucency every time.

The Critical Role of Ramp Rates

Ramp rates, or the speed of heating and cooling, are just as important as the final temperature.

If a furnace heats or cools too quickly, it can introduce internal stresses and micro-fractures into the ceramic, compromising the restoration's long-term durability. Controlled ramp rates are crucial for high-quality, stable results.

Guaranteeing a Perfect Fit

The ultimate goal is a restoration that fits perfectly. A high-quality furnace guarantees this by providing uniform heat distribution and preventing material distortion.

This accuracy eliminates time-consuming chairside adjustments for the dentist and ensures patient satisfaction, building a reputation for reliability.

Driving Lab Efficiency and Profitability

A well-chosen furnace is a direct investment in your lab's operational performance and financial health. It streamlines workflows and maximizes output.

Maximizing Throughput with Chamber Capacity

The chamber size dictates how many units you can sinter in a single cycle.

Carefully evaluating your daily production needs against a furnace's capacity ensures you can meet demand without creating bottlenecks in your workflow.

Reducing Labor with Automation

Modern furnaces feature programmable, pre-set cycles for various materials.

This automation frees up skilled technicians from manually monitoring the firing process, reduces the risk of human error, and ensures consistent, repeatable outcomes for every case.

Shortening the Production Cycle

By combining efficient capacity with automated cycles, a good furnace significantly shortens the overall production timeline from design to finished product.

This time-saving capability allows your lab to increase case turnover and provides a strong economic advantage over labs with slower, more traditional methods.

Understanding the Trade-offs: Features vs. Cost

Selecting a furnace involves balancing advanced capabilities with budget. Understanding the key components helps you make an informed decision about where to invest.

Heating Elements and Build Quality

The heating elements are the heart of the furnace. High-purity silicon carbide (SiC) elements often provide longer service life and cleaner firing than standard alternatives.

Likewise, superior insulation, like dense ceramic fiberboard, improves temperature stability and energy efficiency, reducing operational costs over the furnace's lifetime.

Capacity vs. Lab Footprint

A larger furnace increases throughput but also comes with a higher initial cost and requires more physical space.

Labs must weigh the benefit of processing more units at once against the practical constraints of their budget and facility size.

Advanced Features and Connectivity

Features like Wi-Fi connectivity for remote monitoring or advanced diagnostic programs can enhance workflow management but may not be essential for every lab.

Prioritize features that solve your most pressing operational challenges first, such as precise temperature control and reliability.

Making the Right Choice for Your Lab

Your decision should be guided by your lab's primary goals.

- If your primary focus is high-volume production: Prioritize a furnace with a large chamber capacity and proven, reliable ramp rates to maximize daily throughput.

- If your primary focus is specialized, high-aesthetic restorations: Invest in a furnace with the most precise temperature control and highly programmable, multi-stage cycles.

- If your primary focus is balancing budget and future growth: Choose a model with excellent build quality and durable heating elements, ensuring a long service life and low running costs, even if it has a smaller capacity initially.

Choosing the right furnace is an investment in the quality, consistency, and profitability of every restoration your lab produces.

Summary Table:

| Benefit Category | Key Features | Impact |

|---|---|---|

| Clinical Success | Precise temperature control, uniform heating, controlled ramp rates | Superior strength, fit, and aesthetics of restorations |

| Lab Efficiency | Large chamber capacity, programmable cycles, automation | Increased throughput, reduced labor, shorter production cycles |

| Profitability | Optimized material usage, energy efficiency, reduced errors | Lower costs, higher case turnover, stronger bottom line |

Ready to elevate your dental lab's performance? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer a product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Contact us today via our contact form to discuss how our furnaces can enhance your restoration quality and operational efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations