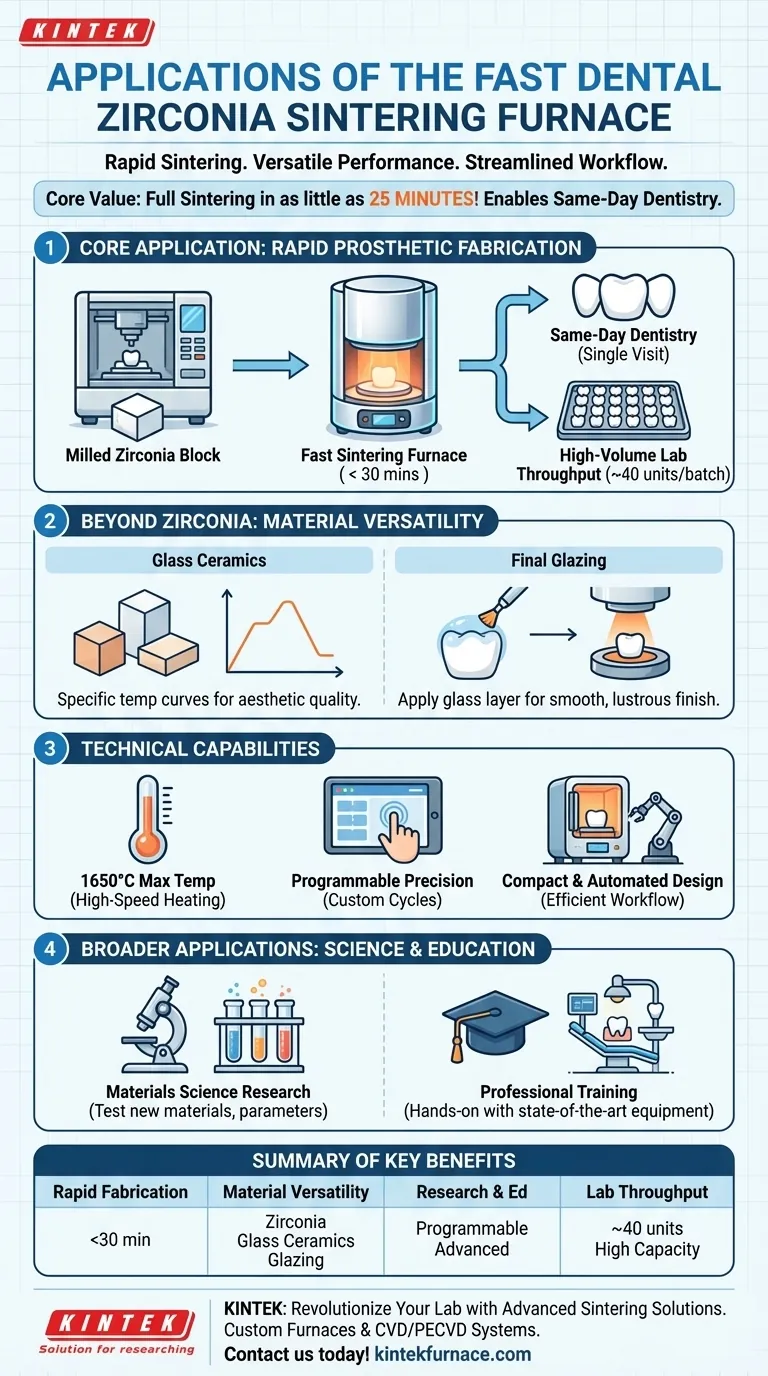

While its name highlights one function, the Fast Dental Zirconia Sintering Furnace is a versatile tool whose applications extend beyond a single material. Its primary use is the rapid sintering of zirconia for dental restorations like crowns and bridges, but it is also applied to other materials like glass ceramics and used widely in research and educational settings for materials science.

The core value of this furnace lies in its ability to dramatically reduce production time for dental prosthetics. By completing a full sintering cycle in as little as 25 minutes, it transforms the dental lab workflow and makes single-visit, "same-day" dentistry a practical reality.

The Core Application: Rapid Prosthetic Fabrication

The most significant application is in the clinical or laboratory setting for creating permanent dental restorations with unprecedented speed. This speed is the furnace's defining feature.

Creating Crowns and Bridges

The furnace is essential for transforming pre-sintered zirconia blocks—milled into the shape of a crown or bridge—into their final, high-strength state. A process that traditionally took hours can now be completed in under 30 minutes.

Enabling "Same-Day" Dentistry

This rapid cycle time is the key technology that enables single-visit restorations. A patient can be scanned, the crown designed and milled, and then sintered in the fast furnace all within one appointment, eliminating the need for temporary crowns and follow-up visits.

Improving Lab Throughput

For dental laboratories, speed translates directly to efficiency. The furnace's ability to process a batch of approximately 40 units in its compact chamber allows for a significant increase in daily production capacity.

Beyond Zirconia: Material Versatility

While optimized for zirconia, these furnaces are not single-purpose devices. Their precise temperature control makes them suitable for processing other critical dental materials.

Sintering Glass Ceramics

The furnace can be programmed to handle the specific temperature curves required for sintering various types of glass ceramics, which are valued for their high aesthetic qualities.

Final Glazing

It is also used for the final step of glazing. This process applies a thin layer of glass to the surface of a restoration, which is then fired to create a smooth, lustrous, and natural-looking finish.

Understanding the Technical Capabilities

The furnace's applications are a direct result of its underlying technology. These features are what deliver its speed, consistency, and versatility.

High-Speed, High-Temperature Heating

The furnace can reach a maximum temperature of 1650°C, powered by high-quality silicon-molybdenum alloy heating elements. This allows it to ramp up to the required sintering temperature for zirconia very quickly.

Programmable Precision

Modern furnaces feature touch screen controls and programmable curve settings. This allows technicians to create and save custom heating and cooling cycles, ensuring consistent and optimal results for different materials and restoration types.

Compact and Automated Design

A small muffle chamber, often around 1 liter, heats up rapidly and efficiently. Features like automated tray handling further streamline the workflow, minimizing manual intervention and ensuring a consistent process.

Broader Applications in Science and Education

Beyond the dental clinic, the fast sintering furnace is a valuable tool in academic and research environments.

Materials Science Research

Research institutions use these furnaces to test the properties of new dental materials, experiment with different sintering parameters, and develop novel ceramics for healthcare applications.

Professional Training

In colleges and universities, these furnaces provide dental technology students with hands-on experience using the same state-of-the-art equipment they will encounter in modern dental labs and clinics.

Making the Right Choice for Your Goal

To determine if this furnace fits your needs, consider your primary objective.

- If your primary focus is rapid, in-house restorations: The fast furnace is the ideal technology for enabling a "same-day dentistry" model in a clinical setting.

- If your primary focus is high-volume lab production: The combination of speed and batch capacity offers a significant boost to workflow efficiency and output.

- If your primary focus is material research: The programmable controls and high-temperature capabilities provide the necessary precision for experimental work.

Ultimately, the fast sintering furnace is a key enabler of modern, efficient, and patient-centric dental care.

Summary Table:

| Application | Key Benefits |

|---|---|

| Rapid Prosthetic Fabrication | Enables same-day dentistry, reduces production time to under 30 minutes |

| Material Versatility | Sinters zirconia, glass ceramics, and handles glazing for diverse dental materials |

| Research and Education | Supports materials science experiments and professional training with programmable controls |

| Lab Throughput Improvement | Processes batches of up to 40 units, increasing daily production capacity |

Ready to revolutionize your dental lab or research with advanced sintering solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique needs in rapid prosthetic fabrication, material testing, and more. Contact us today to boost efficiency and innovation!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity