Fundamentally, a box-type annealing atmosphere furnace is a specialized thermal processing instrument designed for applications where both precise temperature control and the chemical environment are critical. It finds widespread use in the heat treatment of advanced metal alloys, the manufacturing of electronics and ceramics, and the development of new materials like composites and nanomaterials.

The true value of this furnace isn't just heating a material; it's about precisely controlling the chemical environment during heating. This capability is essential for preventing unwanted reactions like oxidation and for achieving specific material properties that are impossible to attain in a standard air furnace.

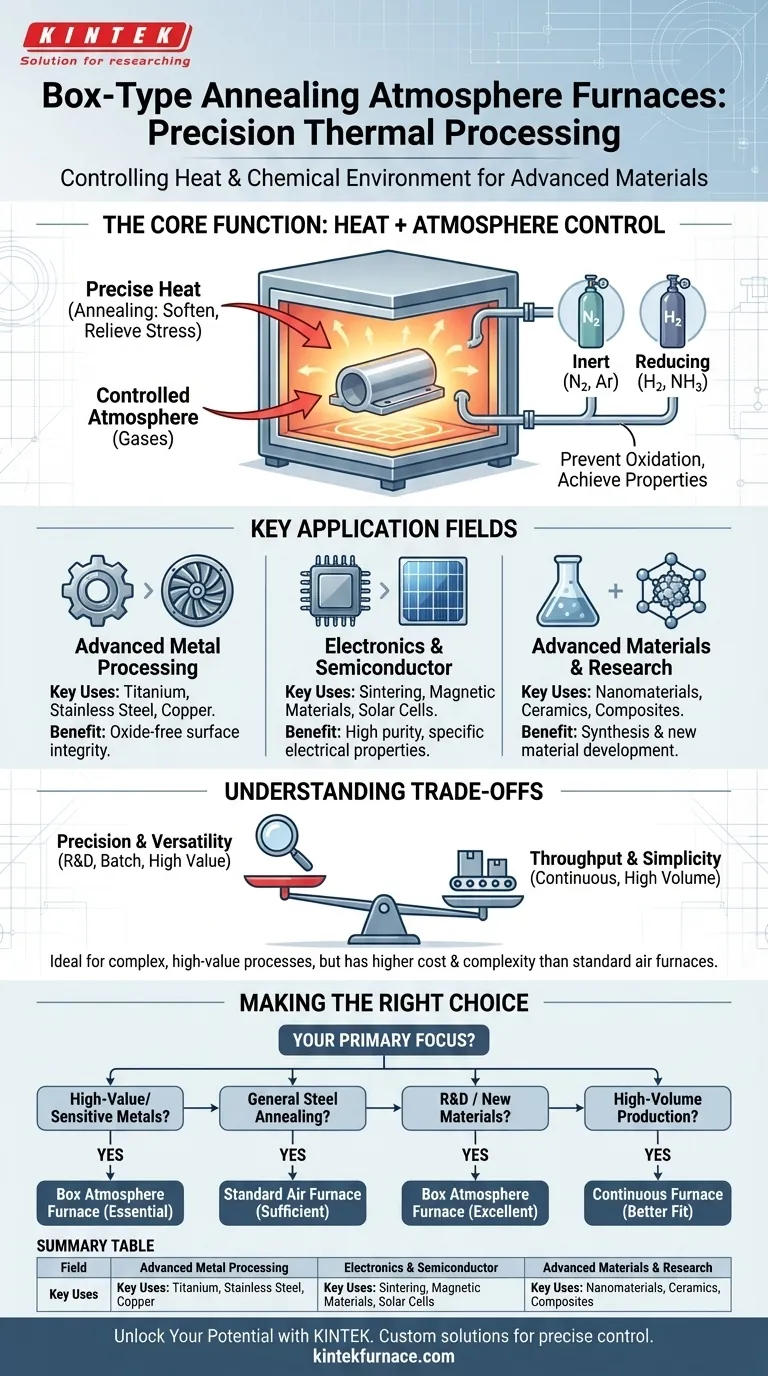

The Core Function: Combining Heat and Atmosphere

A box-type annealing atmosphere furnace is defined by two distinct but interconnected functions. Understanding both is key to knowing when to use it.

The Purpose of Annealing

Annealing is a heat treatment process where a material is heated to a specific temperature, held there for a period, and then cooled at a controlled rate.

The primary goals of annealing are to soften materials, increase their ductility, and relieve internal stresses, which makes them easier to work with or improves their final mechanical properties.

The Critical Role of a Controlled Atmosphere

Many advanced materials, especially at high temperatures, will react with the oxygen and moisture in the air. This can lead to undesirable oxidation, scaling, or decarburization, which degrades the material's surface and performance.

An atmosphere furnace replaces the ambient air with a specific gas or gas mixture. Gases like nitrogen (N₂) and argon (Ar) are inert and used to prevent reactions. Gases like hydrogen (H₂) or decomposed ammonia (NH₃) create a reducing environment to actively remove oxides.

The "Box-Type" Advantage

The "box-type" designation refers to the furnace's physical design: a single chamber for batch processing. This makes it highly versatile for research and development, small-to-medium production runs, and processes involving parts of various shapes and sizes.

Key Application Fields in Detail

The furnace's unique capabilities make it essential in several high-technology fields.

Advanced Metal Processing

This is the most common application area. The furnace is used for annealing or brazing oxygen-sensitive metals where surface integrity is paramount.

Examples include titanium alloys, which are highly reactive with oxygen at elevated temperatures, and stainless steels, where maintaining a bright, oxide-free finish is necessary. It is also used for copper and other non-ferrous alloys.

Electronics and Semiconductor Manufacturing

The production of electronic components often requires sintering powders or annealing parts in an extremely pure environment to achieve the desired electrical and physical properties.

This furnace is used for sintering semiconductor components, preparing magnetic materials, and processing materials for solar cells and other electronic devices where contamination would lead to failure.

Advanced Materials and Research

In laboratories and research settings, this furnace is an indispensable tool for developing and testing new materials.

Its precise control over temperature and atmosphere allows for the synthesis of nanomaterials, the firing of advanced ceramics, the sintering of powdered metals, and the creation of novel composite materials.

Understanding the Trade-offs

While powerful, this furnace is not the universal solution for all heat treatment needs.

Precision vs. Throughput

The batch-based nature of a box furnace is ideal for high-value components, process development, and R&D. However, it is not designed for the high-volume, continuous throughput seen in large-scale manufacturing, where a tunnel or belt furnace would be more appropriate.

Cost and Complexity

Introducing atmosphere control systems, high-integrity seals, and safety protocols (especially for flammable gases like hydrogen) significantly increases the furnace's cost and operational complexity compared to a standard air furnace.

Material and Atmosphere Compatibility

The furnace's construction, typically from high-temperature alloy steel or stainless steel, is robust. However, extremely corrosive process gases or materials may require specialized and even more expensive furnace linings and components.

Making the Right Choice for Your Process

Selecting the correct furnace depends entirely on your material, your process, and your production goals.

- If your primary focus is high-value, oxygen-sensitive metals: A box-type atmosphere furnace is essential to prevent oxidation and ensure desired material properties.

- If your primary focus is general-purpose steel annealing: A simpler and more cost-effective air-atmosphere box furnace may be sufficient if a thin oxide layer is acceptable.

- If your primary focus is research and new material development: The versatility in temperature and atmosphere control makes this furnace an excellent and often necessary investment.

- If your primary focus is high-volume, standardized production: You should evaluate a continuous furnace system (like a belt or roller hearth) designed for your specific process.

By understanding the interplay of heat, atmosphere, and material, you can confidently select the right thermal processing tool for your specific objective.

Summary Table:

| Application Field | Key Uses |

|---|---|

| Advanced Metal Processing | Annealing titanium alloys, stainless steels, copper alloys |

| Electronics and Semiconductor Manufacturing | Sintering semiconductors, magnetic materials, solar cells |

| Advanced Materials and Research | Synthesizing nanomaterials, firing ceramics, creating composites |

Unlock the full potential of your thermal processing with KINTEK! Our box-type annealing atmosphere furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are engineered to deliver precise temperature and atmosphere control for superior results in metals, electronics, and materials research. With our strong deep customization capability, we tailor solutions to meet your unique experimental needs. Contact us today to discuss how we can enhance your lab's efficiency and innovation!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the significance of a controlled atmosphere in a retort furnace? Ensure Purity and Precision in Thermal Processing

- What is the role of the atmosphere control system in a program-controlled atmosphere furnace? Master Precision and Protection

- Why is a fixed-bed reactor system with high-precision temperature control necessary for biochar? Achieve +/-3°C Accuracy

- What is the effect of post-deposition annealing (PDA) on fluoride thin films? Optimize 2D Transistor Performance

- In which fields is the inert atmosphere principle commonly applied? Discover Key Uses in Heat Treatment, Food, and More

- How do high-temperature furnaces facilitate the functionalization of materials? Optimize Biodiesel Catalyst Synthesis

- Why is an inert atmosphere important in heat treatment processes? Prevent Oxidation and Ensure Material Integrity

- How is helium utilized in atmosphere furnaces? Unlock Purity and Rapid Cooling for Superior Results