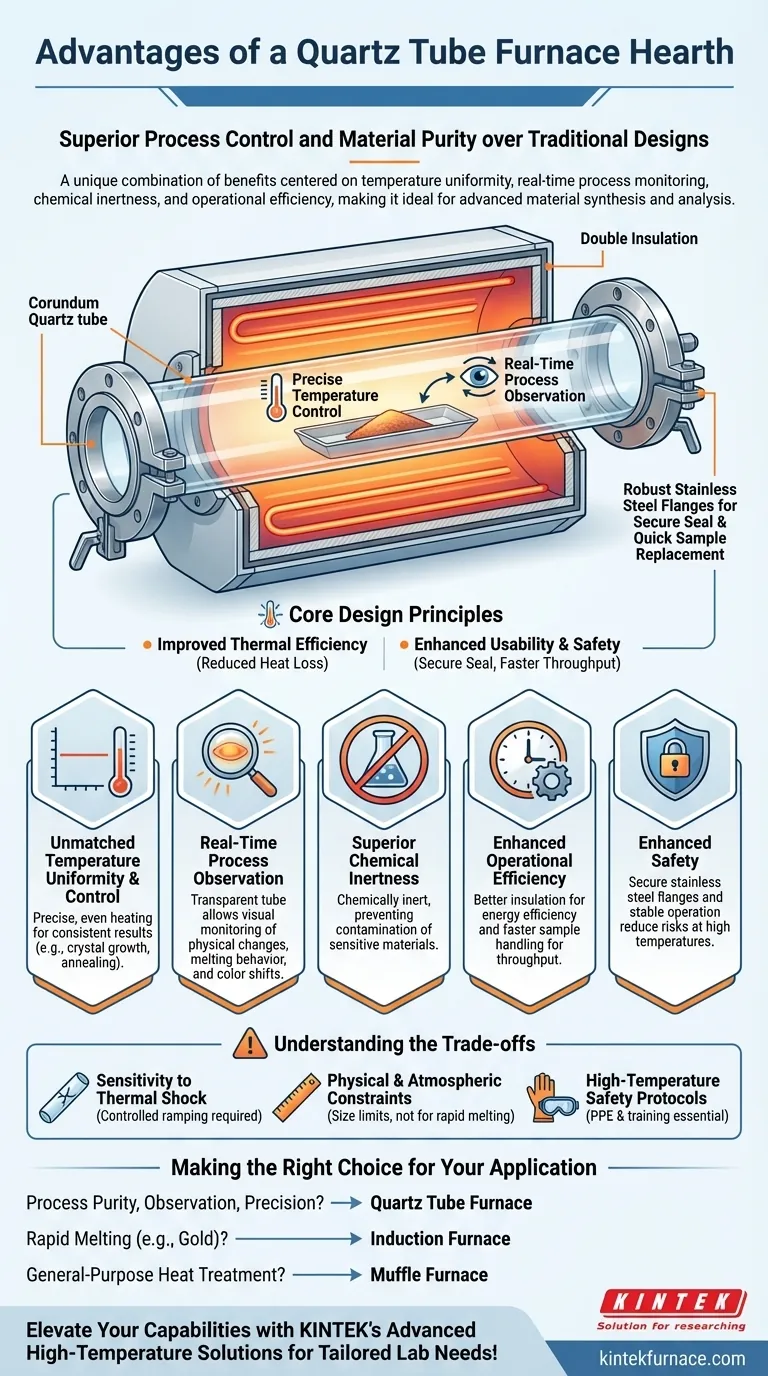

In essence, a quartz tube furnace hearth offers a unique combination of advantages over traditional designs, primarily centered on superior process control and material purity. Its key benefits include exceptional temperature uniformity, the ability to visually monitor processes in real-time, chemical inertness for sensitive materials, and enhanced operational efficiency through better insulation and faster sample handling.

The true value of a quartz tube furnace lies not just in its ability to reach high temperatures, but in its capacity to create a highly controlled, pure, and observable environment. This makes it an indispensable tool for advanced material synthesis and analysis where process integrity is paramount.

The Core Design Principles

A modern quartz tube furnace hearth moves beyond older designs by pairing a corundum quartz tube with stainless steel pipe flanges. This construction is a significant upgrade from previous quartz glass tube and piston compositions.

Improved Thermal Efficiency

The design often incorporates double insulation on the outer wall. This simple feature dramatically reduces heat loss during high-temperature operations like sintering, leading to greater energy efficiency and more stable internal temperatures.

Enhanced Usability and Safety

Using robust stainless steel flanges allows for a more secure seal and quicker sample replacement compared to more fragile or complex systems. This improves laboratory throughput and overall operational safety.

Key Advantages in Material Processing

The specific benefits of a quartz tube furnace make it ideal for demanding laboratory and industrial applications where precision is non-negotiable.

Unmatched Temperature Uniformity and Control

These furnaces are engineered for precise temperature control and highly uniform heating across the entire sample length. This is critical for processes like crystal growth or annealing, where even minor temperature variations can compromise the final product.

Real-Time Process Observation

The most distinct advantage is the transparency of the quartz tube. This allows operators to visually monitor the sample in real-time, observing physical changes, color shifts, or melting behavior as it happens. This direct feedback is invaluable for process development and quality control.

Superior Chemical Inertness

Quartz is chemically inert, meaning it will not react with the vast majority of substances even at extreme temperatures. This makes it the ideal chamber material for handling highly reactive chemicals, preventing contamination of the sample.

Understanding the Trade-offs

While powerful, the quartz tube furnace is a specialized tool with specific limitations that must be respected for safe and effective operation.

Sensitivity to Thermal Shock

Quartz, despite its high-temperature stability, can be susceptible to cracking if heated or cooled too rapidly. Controlled temperature ramping is essential to prevent thermal shock and extend the life of the tube.

Physical and Atmospheric Constraints

The tubular design naturally limits the size and shape of the samples that can be processed. Furthermore, while excellent for creating controlled gas or vacuum atmospheres, they are not typically designed for the rapid, high-volume melting seen in other furnace types like induction furnaces.

High-Temperature Safety Protocols

Operating any equipment that exceeds 1000°C demands strict safety measures. Proper training, personal protective equipment (PPE), and adherence to operational protocols are absolutely necessary to mitigate risks associated with extreme heat.

Making the Right Choice for Your Application

Selecting the correct furnace requires a clear understanding of your primary process goal.

- If your primary focus is process purity, observation, and precision: The quartz tube furnace is the superior choice for synthesizing or treating sensitive materials in a controlled atmosphere.

- If your primary focus is rapidly melting metals like gold: An induction furnace is far more efficient, offering faster melt times and inherent stirring action for a homogenous result.

- If your primary focus is general-purpose heat treatment of non-reactive materials: A simpler, more robust muffle furnace might be a more cost-effective solution.

Ultimately, choosing the right furnace is about matching the tool's unique strengths to your specific scientific or industrial challenge.

Summary Table:

| Advantage | Description |

|---|---|

| Temperature Uniformity | Ensures precise and even heating for consistent results in processes like crystal growth. |

| Real-Time Observation | Allows visual monitoring of samples through the transparent quartz tube for immediate feedback. |

| Chemical Inertness | Prevents contamination by not reacting with sensitive materials, ideal for pure environments. |

| Operational Efficiency | Features better insulation and faster sample handling, improving energy use and throughput. |

| Enhanced Safety | Robust stainless steel flanges provide secure seals and reduce risks during high-temperature operations. |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior process control, purity, and efficiency. Ready to optimize your material synthesis and analysis? Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab