At its core, a modern dental porcelain furnace is a sophisticated, programmable oven. Its key features include a highly accurate programmable controller for managing firing cycles, a vacuum system to ensure material density, a uniform heating chamber for consistency, and a user-friendly digital interface. These components work in unison to transform ceramic materials into durable, biocompatible, and aesthetically pleasing dental restorations like crowns and veneers.

The array of technical features on a dental furnace can feel overwhelming. However, the decision process simplifies when you realize the ultimate goal is to find the furnace whose capabilities for precision, consistency, and efficiency best match the specific materials and workflow of your dental laboratory.

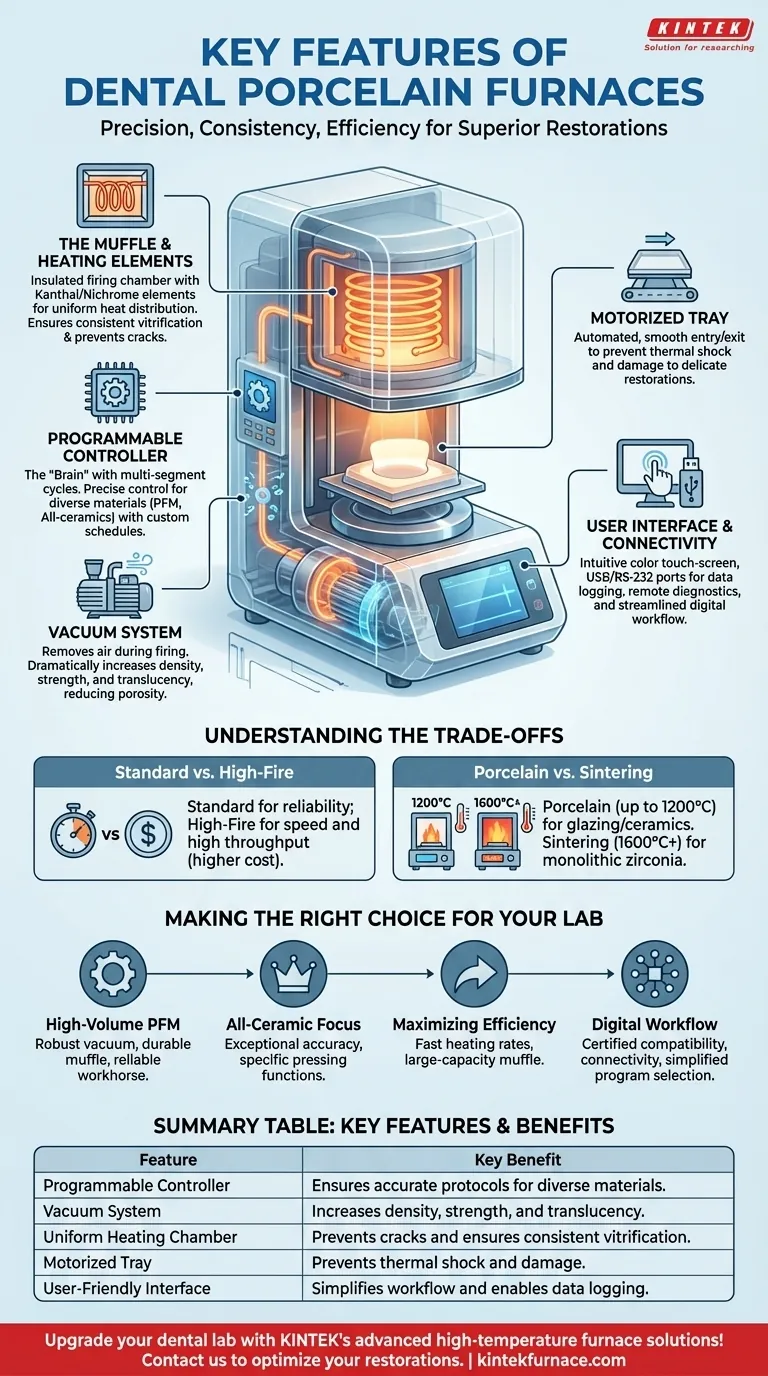

The Anatomy of a Modern Porcelain Furnace

Understanding a furnace's key components reveals how each one contributes directly to the quality of the final restoration. These are not just items on a spec sheet; they are the tools that give a technician control over the final product.

The Muffle and Heating Elements: The Heart of the Furnace

The muffle is the insulated firing chamber where the magic happens. It is lined with heating elements, typically made of Kanthal or Nichrome, designed to distribute heat as evenly as possible.

A uniform heating zone is arguably the most critical feature. It ensures that the entire restoration, regardless of its position on the tray, experiences the same temperature at the same time, which is essential for preventing cracks and achieving consistent vitrification.

The Programmable Controller: The Brain of the Operation

Modern furnaces are defined by their electronic, multi-segment programmable controllers. This allows a technician to create and store custom firing schedules with precise control over every stage.

This programmability is vital for handling the diverse range of modern dental materials, from porcelain-fused-to-metal (PFM) frameworks to advanced all-ceramics like lithium disilicate. Each material has a unique firing protocol, and the controller ensures these are followed perfectly every time.

The Vacuum System: Ensuring Strength and Clarity

A built-in vacuum pump is a standard feature on nearly all porcelain furnaces. During the firing cycle, the vacuum removes air from the muffle, which pulls microscopic air bubbles out of the porcelain as it fuses.

This process dramatically increases the density, strength, and translucency of the final restoration. A furnace with a powerful and reliable vacuum (often rated up to ~980 mBar) produces ceramics that are less porous and more resistant to fracture.

The Motorized Tray: For Gentle Handling

The motorized firing tray automatically and smoothly moves the restoration into and out of the hot chamber. This may seem like a simple convenience, but it serves a critical technical purpose.

By controlling the speed of entry and exit, the motorized lift prevents thermal shock. This rapid temperature change is a common cause of cracks in delicate ceramic structures like veneers or complex bridge frameworks.

The User Interface and Connectivity: Simplifying the Workflow

A modern color touch-screen display has become the standard. It provides an intuitive way to select programs, monitor firing cycles, and adjust parameters without navigating complex menus.

Features like USB ports for data logging or RS-232/RS-485 communication ports allow for quality control, remote diagnostics, and easy transfer of firing programs, streamlining the lab's digital workflow.

Understanding the Trade-offs

Choosing a furnace involves more than simply finding the one with the most features. It requires a clear understanding of your lab's specific needs and the critical distinctions between furnace types.

Standard vs. High-Fire Models

Some furnaces are marketed as "high-fire" or having exceptionally fast heating rates. These are designed for high-throughput labs where reducing firing time by even a few minutes per cycle adds up to significant productivity gains.

However, this speed may come at a higher initial cost. For a smaller lab or one that doesn't operate at maximum capacity, a standard, reliable furnace may offer a better return on investment.

Porcelain vs. Sintering Furnaces: A Critical Distinction

This is a common point of confusion. Porcelain furnaces operate at lower temperatures (up to 1200°C) and are used for glazing, staining, and building up layers of conventional ceramics.

Sintering furnaces, on the other hand, are required for processing monolithic zirconia frameworks. These furnaces must reach much higher temperatures (up to 1600°C or more) to sinter the zirconia from its chalky pre-milled state into a dense, strong final form. While some combination units exist, they are typically distinct devices for different materials and processes.

The Myth of "One Size Fits All"

Virtually any modern furnace can handle a wide range of materials. However, some are specifically optimized for certain tasks. For example, a furnace designed primarily for pressing all-ceramic materials may have features for thermal and pressure control that are superior to a general-purpose unit. Be wary of any single solution claiming to be the absolute best for every application.

Making the Right Choice for Your Lab

Your decision should be guided by the primary type of work your lab produces.

- If your primary focus is high-volume PFM and conventional ceramics: A reliable, programmable electric furnace with a robust vacuum system and a durable muffle is your essential workhorse.

- If your primary focus is all-ceramic restorations (e.g., lithium disilicate): Prioritize a furnace with exceptional temperature accuracy, specific pressing functions, and pre-loaded programs for these materials.

- If your primary focus is maximizing efficiency and throughput: A model with fast heating rates and a large-capacity muffle could provide a significant return on investment.

- If your primary focus is integration with a digital workflow (e.g., CEREC/inLab): Look for furnaces with certified compatibility, network connectivity, and simplified program selection for chairside blocks.

Ultimately, the right furnace is an investment in repeatable quality and a more efficient workflow.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Programmable Controller | Manages firing cycles with precision | Ensures accurate protocols for diverse materials |

| Vacuum System | Removes air during firing | Increases density, strength, and translucency |

| Uniform Heating Chamber | Distributes heat evenly | Prevents cracks and ensures consistent vitrification |

| Motorized Tray | Automates entry/exit of restorations | Prevents thermal shock and damage |

| User-Friendly Interface | Color touch-screen with connectivity | Simplifies workflow and enables data logging |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, enhancing efficiency and quality for PFM, all-ceramics, and digital workflows. Contact us today to discuss how our furnaces can optimize your restorations and boost productivity!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab