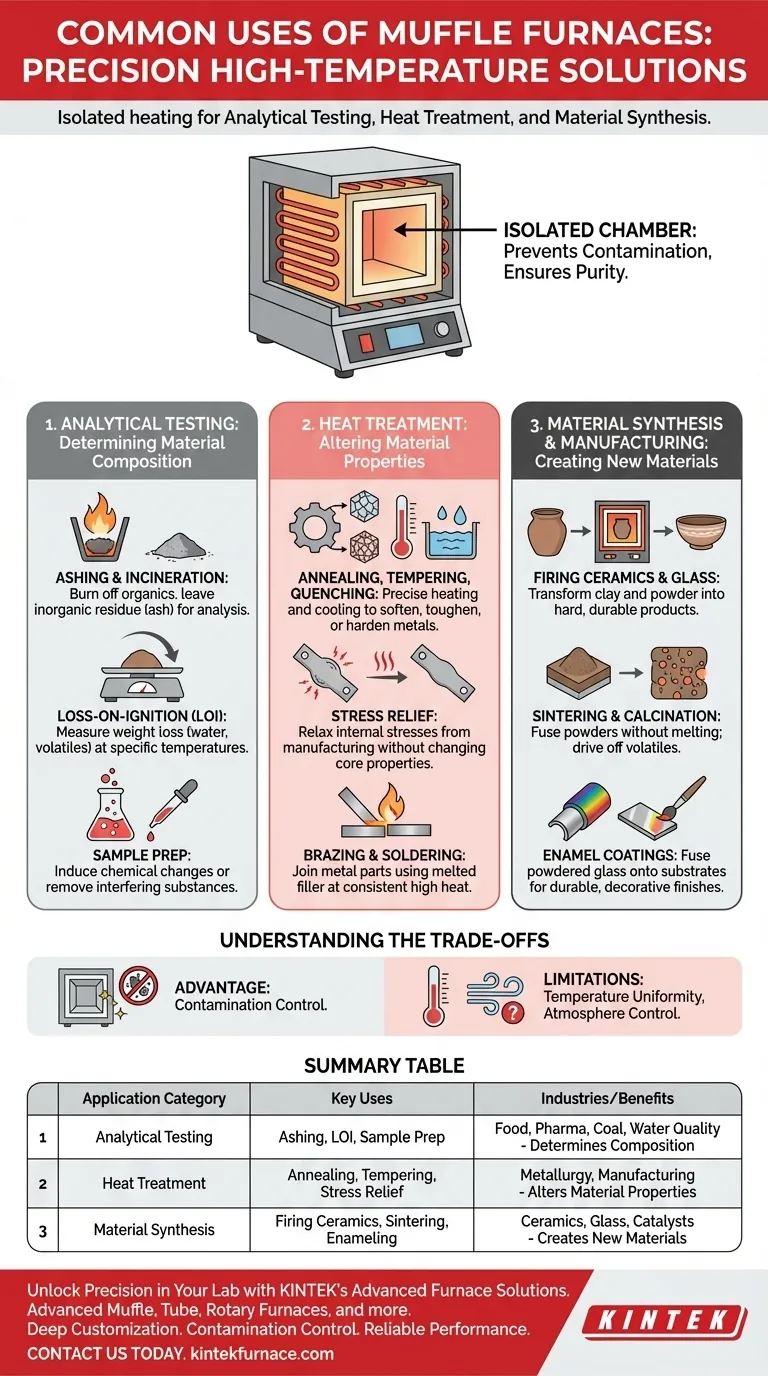

In essence, muffle furnaces are high-temperature ovens used for a wide range of analytical, treatment, and manufacturing processes. Their most common applications fall into three main categories: determining the composition of a material through burning (ashing), altering the physical properties of metals through heat treatment, and creating new materials like ceramics and glass.

A muffle furnace's core function is to provide an extremely hot, controlled environment that is isolated from the heating elements. This separation, known as the "muffle," prevents contamination of the sample, making it indispensable for processes requiring high purity and precision.

Analytical Testing: Determining Material Composition

The most prevalent use of muffle furnaces is in analytical laboratories for determining the inorganic and non-volatile components of a sample.

Ashing and Incineration

Ashing is a process where a sample is heated to a high temperature to burn off all organic matter. This leaves behind an inorganic, non-combustible residue, or ash.

This technique is fundamental for quality control and chemical analysis in industries ranging from food science and pharmaceuticals to coal and water quality testing. The weight of the remaining ash helps determine the sample's composition.

Loss-on-Ignition (LOI)

Closely related to ashing, loss-on-ignition measures the total weight lost from a sample when it is heated to a specific temperature. This value typically represents the content of water, carbon, and other volatile substances.

General Sample Preparation

Muffle furnaces are also used to prepare samples for further, more detailed analysis. For example, a sample might be heated to induce a specific chemical change or to remove interfering substances before it is analyzed with other instruments.

Heat Treatment: Altering Material Properties

Muffle furnaces are a cornerstone of metallurgy and materials science, used to precisely alter the microstructure and physical properties of metals and alloys.

Annealing, Tempering, and Quenching

Annealing involves heating a metal and then cooling it slowly to make it softer and more ductile, relieving internal stresses.

Tempering is used to increase the toughness of hardened steels, while quenching involves rapid cooling to lock in specific structural properties. These processes are critical for manufacturing tools, machine parts, and structural components.

Stress Relief

Components can accumulate internal stress during manufacturing processes like welding or machining. Heating them in a muffle furnace to a temperature below their critical transformation point allows these stresses to relax without changing the material's core properties.

Brazing and Soldering

These processes join metal parts together using a filler metal that is melted at high temperature. A muffle furnace provides the consistent, uniform heat required for strong and reliable joints.

Material Synthesis and Manufacturing

Beyond analysis and treatment, muffle furnaces are instrumental in the creation of new materials and products.

Firing Ceramics and Glass

The precise temperature control of a muffle furnace is essential for firing ceramics, a process that transforms soft clay into a hard, durable final product. It is also used in glass manufacturing and fusing.

Sintering and Calcination

Sintering is a process that uses heat to fuse powdered materials together into a solid mass without melting them completely. It is used to create everything from ceramic parts to metallic components.

Calcination involves heating a material to drive off volatile substances and induce a phase transition or chemical decomposition, a key step in producing cement and certain catalysts.

Creating Enamel Coatings

Enameling involves fusing a layer of powdered glass onto a substrate, usually metal, to create a hard, durable, and decorative coating. The muffle furnace provides the high heat needed to melt the glass powder and bond it to the surface.

Understanding the Trade-offs

While incredibly versatile, a muffle furnace is not always the best tool for every high-temperature job. Understanding its core design is key to knowing when to use it.

The Key Advantage: Contamination Control

The defining feature of a muffle furnace is the ceramic chamber (the muffle) that isolates the sample from the heating elements. This prevents any particles from the heating coils from contaminating the sample, which is critical for analytical work and high-purity applications.

Limitation: Temperature Uniformity

While generally good, the temperature inside a muffle furnace may not be perfectly uniform. For applications requiring extreme temperature precision across a large volume, a specialized convection or vacuum furnace might be more appropriate.

Limitation: Atmosphere Control

A standard muffle furnace operates with a normal air atmosphere. While some models allow for the introduction of inert gases, processes requiring a specific reactive atmosphere or a hard vacuum typically demand a purpose-built furnace.

Making the Right Choice for Your Goal

To determine if a muffle furnace fits your needs, consider your primary objective.

- If your primary focus is quantitative analysis: A muffle furnace is the standard tool for ashing, incineration, and loss-on-ignition to determine material composition for quality control.

- If your primary focus is metallurgy or materials science: The furnace is essential for performing fundamental heat treatments like annealing, tempering, and stress relief on metal samples.

- If your primary focus is fabrication or manufacturing: Use a muffle furnace for high-temperature synthesis processes like firing ceramics, creating enamel coatings, or sintering powdered materials.

Ultimately, a muffle furnace is the definitive tool when you need to apply clean, high heat to analyze, alter, or create materials with precision.

Summary Table:

| Application Category | Key Uses | Industries/Benefits |

|---|---|---|

| Analytical Testing | Ashing, Loss-on-Ignition, Sample Prep | Food, Pharma, Coal, Water Quality - Determines composition |

| Heat Treatment | Annealing, Tempering, Stress Relief | Metallurgy, Manufacturing - Alters material properties |

| Material Synthesis | Firing Ceramics, Sintering, Enameling | Ceramics, Glass, Catalysts - Creates new materials |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet unique experimental requirements. Whether you're in analytical testing, heat treatment, or material synthesis, our furnaces deliver contamination control and reliable performance to enhance your processes.

Contact us today to discuss how we can tailor a solution for your specific needs and boost your lab's efficiency – Get in touch now!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?