In short, vacuum heat treatment for brass offers a superior alternative to traditional methods by producing a clean, bright surface finish and highly uniform metallurgical properties. This is achieved by removing oxygen from the environment during heating, which prevents oxidative discoloration and material loss, thereby eliminating the need for subsequent acid cleaning processes.

The true advantage of vacuum heat treatment is not just an improved final product, but a fundamentally more efficient and controllable manufacturing process. It shifts the focus from correcting defects like scaling and discoloration to preventing them from occurring in the first place.

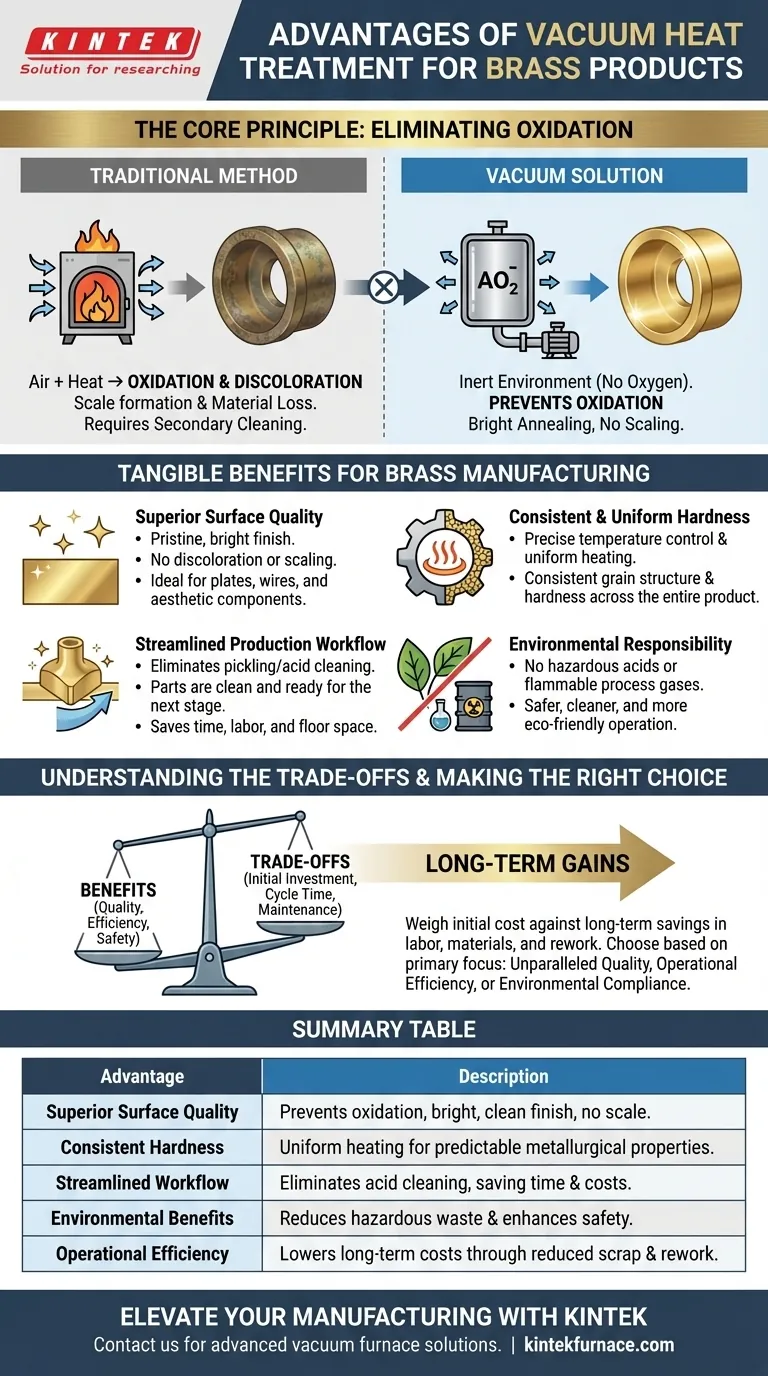

The Core Principle: Eliminating Oxidation

To understand the benefits, you must first understand the problem vacuum furnaces solve: the reaction between hot metal and the air.

How Traditional Treatment Causes Issues

In a standard atmosphere furnace, the combination of high heat and oxygen in the air causes a chemical reaction on the surface of the brass.

This process, known as oxidation, creates a layer of scale and discoloration. It also leads to a small amount of material loss from the surface of the product.

The Vacuum Solution: A Pure Environment

A vacuum furnace works by pumping nearly all of the air out of the sealed chamber before the heating process begins.

By removing the oxygen, you remove a key ingredient for the oxidation reaction. The brass parts are heated in an inert environment, preventing any surface degradation.

The Result: Bright Annealing

This process is often called bright annealing because the brass parts emerge from the furnace with the same bright, clean surface they had going in. There is no discoloration, scaling, or contamination.

Tangible Benefits for Brass Manufacturing

Preventing oxidation creates a cascade of advantages that impact quality, efficiency, and environmental compliance.

Superior Surface Quality

The most immediate benefit is a pristine surface finish. Because no oxidation occurs, there is no need to budget for material loss or worry about inconsistent coloration.

This is especially critical for brass plates, wires, and other components where surface appearance and integrity are paramount.

Consistent and Uniform Hardness

Vacuum furnaces allow for exceptionally precise temperature control and uniform heating. The absence of air currents ensures that every part of the component, from the outer surface to the inner core, reaches the same temperature at the same rate.

This uniformity results in a more consistent grain structure and, therefore, more predictable and uniform hardness across the entire product.

Streamlined Production Workflow

With traditional methods, oxidized parts must be cleaned using a scale-removal pickling process, which involves dipping them in acid baths.

Vacuum treatment completely eliminates this secondary step. Parts come out of the furnace clean and ready for the next stage of manufacturing, saving significant time, labor, and factory floor space.

Environmental Responsibility

Pickling acids are hazardous, requiring careful handling and costly disposal procedures that create environmental challenges.

By making pickling unnecessary, vacuum heat treatment helps create a safer, cleaner, and more environmentally friendly operation. It also removes the need for flammable process gases like hydrogen that are sometimes used in atmospheric furnaces.

Understanding the Trade-offs

While highly advantageous, vacuum heat treatment is not a universal solution without its own considerations. It is essential to weigh the benefits against the operational realities.

Initial Equipment Investment

Vacuum furnaces represent a significant capital investment compared to some simpler atmospheric furnace models. The long-term cost savings in labor, materials, and rework must be weighed against this upfront expense.

Process Cycle Time

Vacuum heat treatment is a batch process. Pumping down the chamber to create the vacuum adds time to the beginning of each cycle. For certain extremely high-volume, continuous production lines, this may be a limiting factor compared to continuous belt furnaces.

Maintenance Complexity

The high-tech components of a vacuum furnace, including the pumps and seals, require a specific and diligent maintenance schedule to ensure optimal performance and longevity.

Making the Right Choice for Your Goal

Ultimately, the decision to use vacuum heat treatment depends on your primary objective for your brass products.

- If your primary focus is unparalleled quality and performance: Vacuum treatment is the definitive choice for achieving a flawless surface finish and the most uniform hardness possible.

- If your primary focus is operational efficiency and cost reduction: The elimination of secondary cleaning processes and reduced material scrap delivers significant long-term savings that can justify the initial investment.

- If your primary focus is environmental compliance and safety: Vacuum treatment provides a clear advantage by removing hazardous pickling acids and flammable gases from your workflow.

By preventing defects at their source, vacuum heat treatment empowers you to produce higher-quality brass components more efficiently and responsibly.

Summary Table:

| Advantage | Description |

|---|---|

| Superior Surface Quality | Prevents oxidation, resulting in a bright, clean finish without discoloration or scaling. |

| Consistent Hardness | Provides uniform heating for predictable hardness and metallurgical properties. |

| Streamlined Workflow | Eliminates acid cleaning steps, saving time, labor, and costs. |

| Environmental Benefits | Reduces hazardous waste and flammable gas use, enhancing safety and compliance. |

| Operational Efficiency | Lowers long-term costs by reducing material loss and rework, despite higher initial investment. |

Ready to elevate your brass manufacturing with advanced vacuum heat treatment? KINTEK specializes in high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, designed for precise temperature control and deep customization to meet your unique needs. Our expertise in R&D and in-house manufacturing ensures reliable performance for diverse laboratory applications. Contact us today to discuss how we can enhance your product quality and operational efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control