In short, a digital muffle furnace is a critical tool in any industry that requires precise, high-temperature heating for material testing, transformation, or sample preparation. Its applications are found across pharmaceuticals, materials science, environmental analysis, and manufacturing for a variety of quality control and research purposes.

The core value of a digital muffle furnace isn't just its ability to reach high temperatures, but its capacity to do so within a highly controlled, isolated chamber. This prevents contamination and ensures uniform heating, which is essential for obtaining accurate and repeatable results.

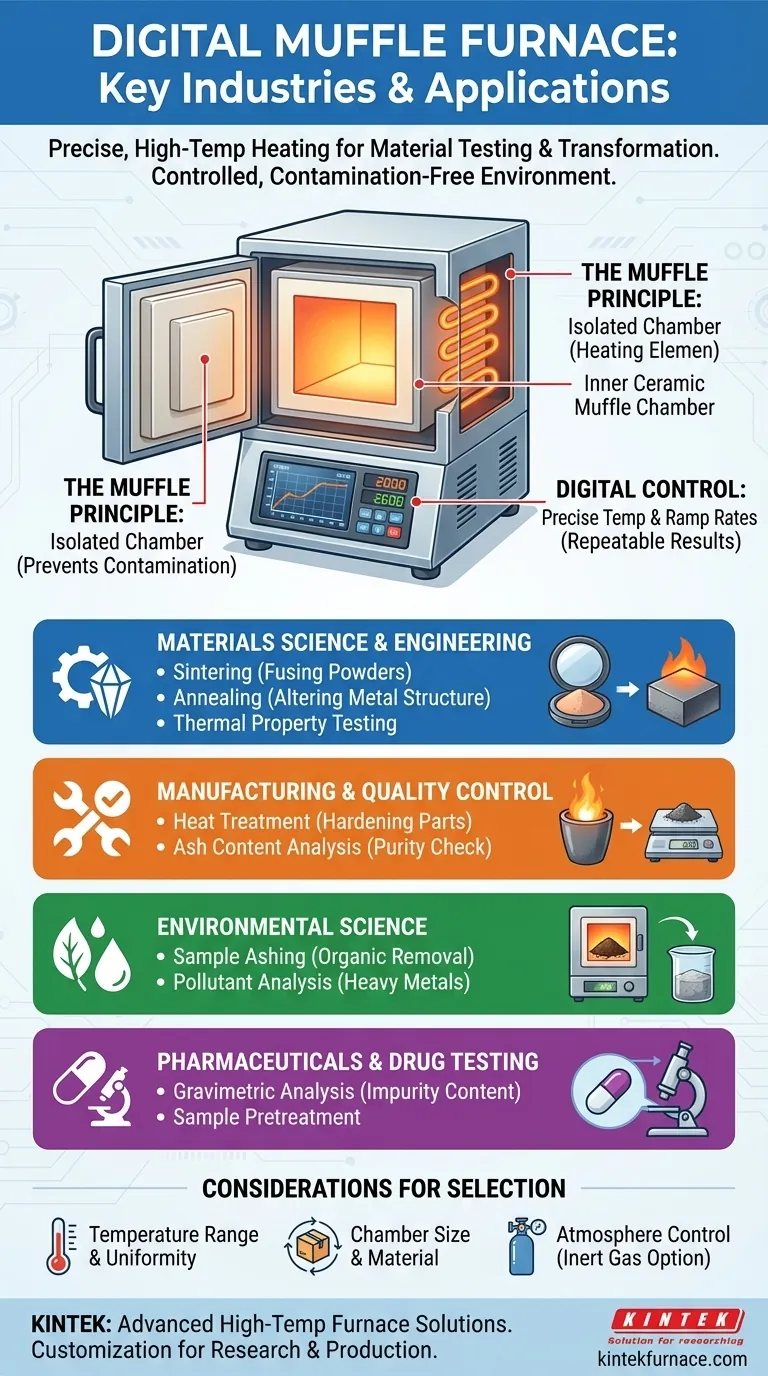

The Core Function: Why a Muffle Furnace is Essential

A muffle furnace is fundamentally a high-temperature oven with a critical design feature: the heating elements are physically separated from the internal chamber.

The "Muffle" Principle

The term muffle refers to the insulated inner chamber that contains the sample. This chamber heats up through convection and radiation from the external heating elements, rather than direct exposure.

This design achieves two primary goals. First, it protects the sample from any potential contamination from the heating elements. Second, it shields the heating elements from any fumes or materials released by the sample, extending the furnace's lifespan.

The Role of Digital Control

Modern digital controllers are what make these furnaces so versatile and reliable. They allow operators to program and maintain precise temperatures, set heating and cooling rates, and run automated cycles. This level of control is non-negotiable for scientific research and stringent quality control processes.

Key Industrial Applications in Detail

The combination of isolated, uniform, and controllable high-temperature heating makes the muffle furnace indispensable across several key sectors.

Materials Science and Engineering

This field relies on muffle furnaces for both creating and testing new materials. Common uses include sintering (fusing powdered materials together with heat), annealing (altering a metal's microstructure to make it more workable), and determining the thermal properties of ceramics, metals, and composites.

Manufacturing and Quality Control

In manufacturing, furnaces are used for the heat treatment of small parts to harden or temper them. More commonly, they are used in quality control labs to perform ash content analysis.

By burning a sample of a product (like plastic, rubber, or food) at a controlled temperature, analysts can measure the remaining non-combustible inorganic material (ash). This is a critical indicator of material purity and composition.

Environmental Science

Environmental labs use muffle furnaces extensively for sample preparation. To analyze soil, sludge, or water for heavy metals or other inorganic pollutants, the organic components of the sample must first be removed.

Placing the sample in a muffle furnace cleanly burns off the organic matter through a process called ashing. This leaves behind only the inorganic residue, which can then be dissolved and analyzed with much greater accuracy.

Pharmaceuticals and Drug Testing

The pharmaceutical industry operates under extremely strict quality standards. Muffle furnaces are used for gravimetric analysis, where a drug or component is burned to determine its inorganic impurity content. This helps verify the purity and consistency of a product. It is also used in the pretreatment of samples before they undergo more complex analytical procedures.

Understanding the Trade-offs and Considerations

While highly useful, not all muffle furnaces are the same. The right choice depends entirely on the intended application.

Temperature Range and Uniformity

The required temperature is the first consideration. Basic quality control ashing might only require 500-600°C, while some materials science applications can demand temperatures exceeding 1200°C. Equally important is temperature uniformity—how consistent the temperature is throughout the entire chamber.

Chamber Size and Material

The furnace chamber must be large enough to accommodate your samples. The chamber's material is also a factor; most are made of durable ceramic fiber, but specialized applications might require quartz or other materials to prevent any chemical reaction with the sample at high temperatures.

Atmosphere Control

Standard muffle furnaces operate with an air atmosphere. However, heating certain metals or materials in the presence of oxygen will cause them to oxidize, ruining the sample. For these applications, a more advanced furnace with atmosphere control is necessary, allowing operators to pump in an inert gas like nitrogen or argon to create a non-reactive environment.

Making the Right Choice for Your Goal

Selecting the right equipment requires matching its capabilities to your primary objective.

- If your primary focus is analytical testing and sample preparation: Prioritize a furnace with exceptional temperature accuracy and uniformity for repeatable ashing results.

- If your primary focus is materials development or heat treatment: You need a furnace with a high maximum temperature, potentially fast heating/cooling rates, and the option for atmosphere control.

- If your primary focus is routine quality control: A robust, easy-to-operate furnace with a chamber size suited to your typical batch of samples is the most cost-effective choice.

Ultimately, the digital muffle furnace is a cornerstone tool for any process that demands the precise thermal transformation of a material in a clean environment.

Summary Table:

| Industry | Primary Applications | Key Benefits |

|---|---|---|

| Materials Science & Engineering | Sintering, annealing, thermal property testing | Uniform heating, contamination-free environment |

| Manufacturing & Quality Control | Heat treatment, ash content analysis | Precise temperature control, repeatable results |

| Environmental Science | Sample ashing for pollutant analysis | Clean organic removal, accurate inorganic residue |

| Pharmaceuticals & Drug Testing | Gravimetric analysis, sample pretreatment | High purity standards, reliable impurity detection |

Ready to enhance your lab's precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—whether for materials science, pharmaceuticals, environmental analysis, or quality control. Contact us today to discuss how our tailored solutions can drive your research and production forward!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits