In short, split tube furnaces are used across research and industry for any thermal process that requires precise temperature control combined with easy access to the sample. Their core applications include materials synthesis like chemical vapor deposition (CVD), advanced materials testing, catalyst research, and the heat treatment of pre-assembled components that cannot be easily inserted into a standard furnace tube.

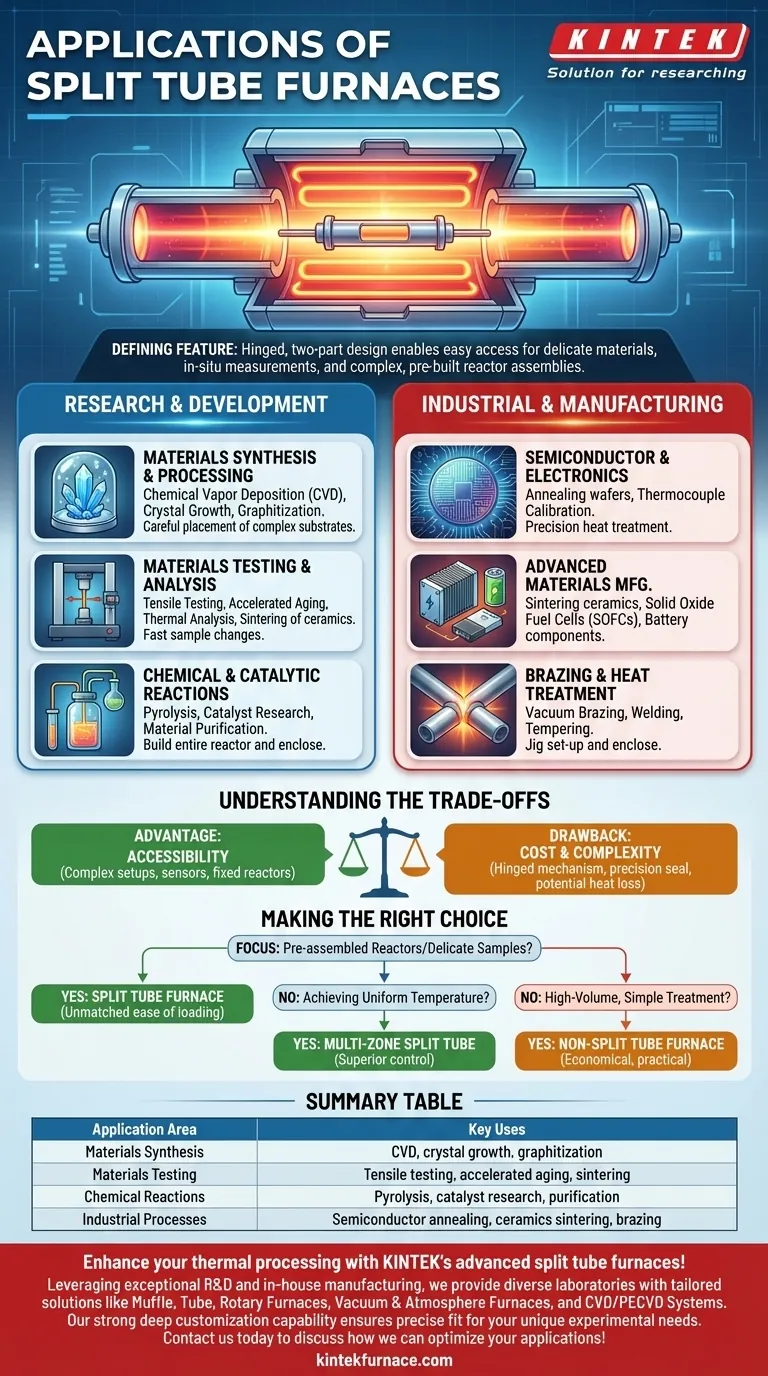

The defining feature of a split tube furnace is not just its ability to generate high, uniform heat, but its hinged, two-part design. This allows the furnace to open and close around a sample, making it the ideal choice for processes involving delicate materials, in-situ measurements, or complex, pre-built reactor assemblies.

Core Applications in Research & Development

The versatility of the split tube furnace makes it a cornerstone of modern materials science and chemistry laboratories. Its design solves several key experimental challenges.

Materials Synthesis and Processing

Split tube furnaces are critical for creating new materials. Their precise temperature and atmosphere control are essential for processes where atomic-level structure is paramount.

Applications include Chemical Vapor Deposition (CVD) for creating thin films, crystal growth, and the graphitization of carbon materials. The ability to open the furnace allows researchers to carefully place complex substrates or seed crystals exactly where needed within the uniform heat zone.

Materials Testing and Analysis

Understanding how materials behave at high temperatures is fundamental to engineering. A split tube furnace facilitates this by allowing test equipment to be integrated directly with the sample.

This is common in tensile testing, where a material is heated and pulled apart simultaneously. It's also used for accelerated aging studies, thermal analysis, and sintering studies on ceramic powders, where sample changes must be fast and easy.

Chemical and Catalytic Reactions

Many chemical reactions require carefully controlled thermal energy. Split tube furnaces provide the ideal environment for studying these processes on a lab scale.

Key uses include pyrolysis (thermal decomposition in an inert atmosphere), catalyst research, and material purification through processes like sublimation. Researchers can build an entire reactor with gas lines and probes, place it in the furnace, and then close the chamber to begin the experiment.

Industrial and Manufacturing Processes

Beyond the lab, split tube furnaces are employed in specialized manufacturing where precision and reliability are non-negotiable.

Semiconductor and Electronics Production

The manufacturing of electronic components often relies on heat treatment. Split tube furnaces are used for annealing semiconductor wafers to repair crystal damage and for the precise calibration of thermocouples used in other industrial equipment.

Advanced Materials Manufacturing

The production of next-generation materials often mimics lab-scale processes. This includes the sintering of ceramics to create dense, hard parts, and the development of solid oxide fuel cells (SOFCs) and advanced battery components.

Brazing and Heat Treatment

The split design is highly advantageous for joining or treating awkwardly shaped metal parts. Components can be set up in a jig, and the furnace is simply closed around them for vacuum brazing, welding, or tempering under a controlled atmosphere, preventing oxidation.

Understanding the Trade-offs

While powerful, a split tube furnace is not always the necessary choice. Understanding its specific advantages and disadvantages is key to making a sound investment.

The Core Advantage: Accessibility

The primary reason to choose a split tube furnace is sample accessibility. If your process involves materials that are difficult to slide down a long tube, have attached sensors or probes, or are part of a fixed reactor setup, the split design is a necessity.

The Drawback: Cost and Complexity

The hinged mechanism and precision engineering required for a good seal make split tube furnaces inherently more complex and expensive than their solid, non-split counterparts. The seam can also be a minor point of heat loss, though this is minimal in high-quality designs.

When a Simpler Furnace Suffices

For high-throughput applications involving simple samples, like calcining powders or drying granular materials that can be easily loaded into a crucible and pushed into the furnace, a standard, non-split tube furnace is often a more economical and robust solution.

Making the Right Choice for Your Application

Your final decision should be guided by the unique demands of your process.

- If your primary focus is processing pre-assembled reactors or delicate samples: The split tube furnace is the unequivocal choice for its unmatched ease of loading.

- If your primary focus is achieving the most uniform temperature profile possible: A multi-zone split tube furnace offers superior control for sensitive processes like crystal growth or CVD.

- If your primary focus is high-volume, simple heat treatment of powders or small parts: A more economical, non-split tube furnace may be the more practical and cost-effective tool.

Ultimately, selecting the right furnace comes down to matching the equipment's design features to your specific operational needs.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Materials Synthesis | CVD, crystal growth, graphitization |

| Materials Testing | Tensile testing, accelerated aging, sintering |

| Chemical Reactions | Pyrolysis, catalyst research, purification |

| Industrial Processes | Semiconductor annealing, ceramics sintering, brazing |

Enhance your thermal processing with KINTEK's advanced split tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs. Contact us today to discuss how we can optimize your applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents