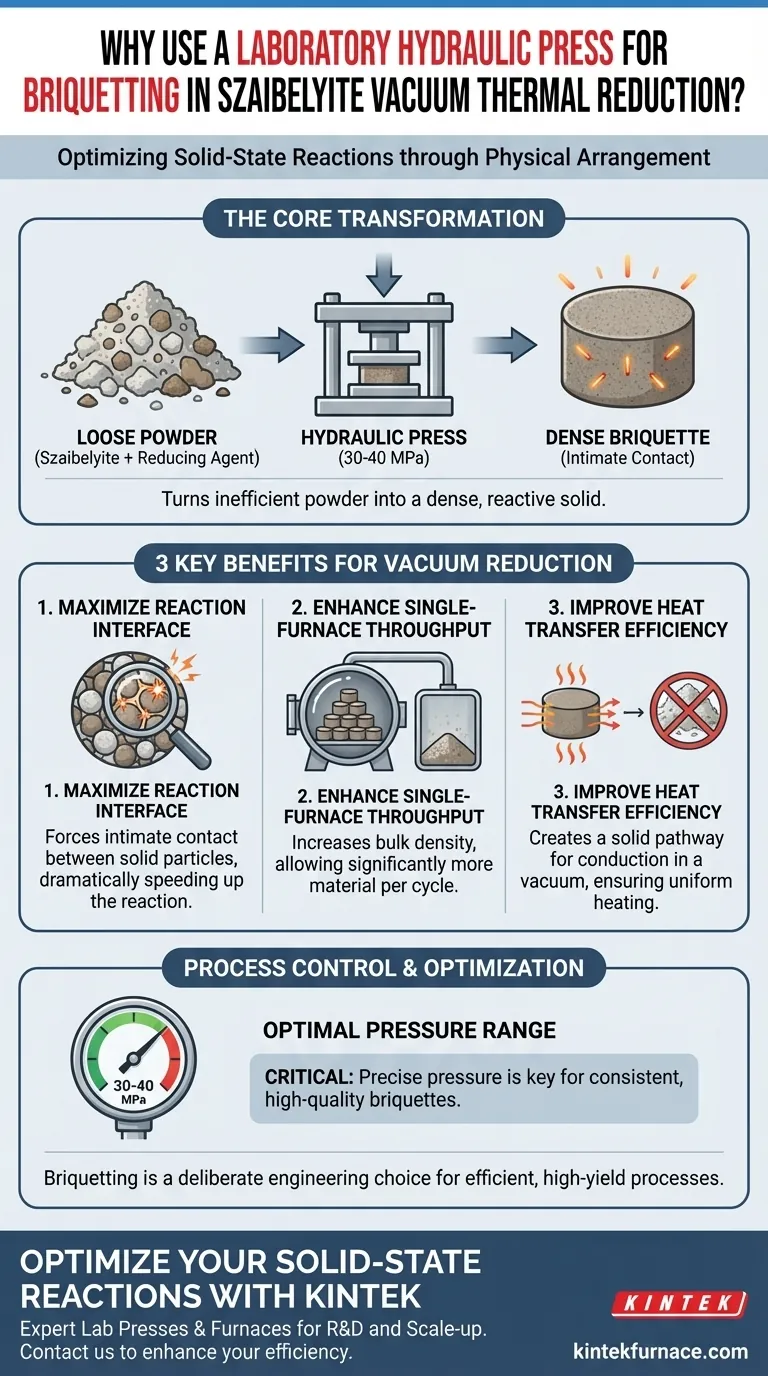

In short, a laboratory hydraulic press is used to compact the mixed powders into dense briquettes, a critical step that directly enhances the reaction's speed, efficiency, and overall throughput. This process physically forces the reacting particles into close contact, increases the amount of material that can be processed at once, and improves how heat moves through the mixture in the vacuum furnace.

The core principle is this: in a solid-state vacuum reaction, success depends on optimizing the physical arrangement of the reactants. Briquetting with a hydraulic press is the mechanical tool used to create this optimal physical state, transforming a loose, inefficient powder into a dense, highly reactive solid.

The Critical Role of Briquetting in Vacuum Reduction

In the vacuum thermal reduction of szaibelyite to produce magnesium, the reaction occurs between solid particles. Unlike reactions in liquids or gases where molecules can move freely, solid-state reactions are entirely dependent on the surface area where the particles touch. A hydraulic press fundamentally re-engineers this physical environment.

Maximizing the Reaction Interface

The primary function of the press is to ensure intimate contact between the szaibelyite ore and the reducing agent, such as silicon powder.

By applying significant pressure (e.g., 30-40 MPa), the press eliminates voids and forces these solid particles against each other. This dramatically maximizes the reaction interface, or the total surface area where the chemical reduction can actually occur.

Without this forced contact, the reaction would be incredibly slow and incomplete, as only a small fraction of the reactant particles would be touching.

Enhancing Single-Furnace Throughput

A secondary, but economically vital, function is to increase the bulk density of the material. Loose powder contains a large amount of empty space.

Compacting the powder into a dense briquette allows a much greater mass of material to be loaded into the furnace for a single cycle. This directly enhances the single-furnace throughput, making the entire process more productive and cost-effective.

Improving Heat Transfer Efficiency

A vacuum is an excellent insulator, meaning heat does not travel easily. Heat transfer through convection (the movement of hot gas) is eliminated.

Therefore, the process relies on conduction—heat moving directly from particle to particle. A dense, compacted briquette provides a much better pathway for heat conduction than a loose powder with many air gaps.

This improved heat transfer ensures the entire material mass reaches the required reaction temperature uniformly, leading to a more efficient and complete reduction of the magnesium.

Understanding the Process Constraints

While essential, the briquetting step is not without its critical parameters. The goal is to achieve an optimal density without introducing other problems.

The Importance of Correct Pressure

The pressure applied by the hydraulic press must be carefully controlled. The specified range of 30-40 MPa is a result of process optimization.

If the pressure is too low, the briquettes will lack sufficient density. This results in poor particle contact, inefficient heat transfer, and lower throughput.

If the pressure is too high, it may not provide additional benefits and could potentially damage the equipment or create briquettes that are too non-porous for the magnesium vapor to escape effectively.

The Challenge of Uniformity

Achieving perfect uniformity in every briquette is a practical challenge. Any variation in density or composition from one briquette to another can lead to non-uniform heating and reaction rates within the furnace.

This can result in lower overall yield and less predictable outcomes, highlighting the importance of a well-maintained press and a consistent mixing procedure.

Making the Right Choice for Your Goal

Controlling the physical form of your reactants is as crucial as controlling the chemical conditions. How you approach briquetting depends on your primary objective.

- If your primary focus is maximizing reaction speed and yield: Ensure the press achieves the target pressure to guarantee intimate contact between the szaibelyite and the reducing agent.

- If your primary focus is improving economic viability: Concentrate on how briquetting increases bulk density, as this directly translates to higher furnace throughput and lower operational costs per unit of magnesium produced.

- If your primary focus is ensuring process consistency: Prioritize uniform briquette density, as this is key to achieving the even heat transfer required for a predictable and complete reaction in a vacuum environment.

Ultimately, using a hydraulic press is a deliberate engineering choice to overcome the inherent physical limitations of a solid-state reaction in a vacuum.

Summary Table:

| Briquetting Function | Key Benefit for Vacuum Reduction |

|---|---|

| Maximizes Reaction Interface | Forces szaibelyite and reducing agent particles into intimate contact, dramatically speeding up the solid-state reaction. |

| Increases Bulk Density | Allows more material to be processed per furnace cycle, improving throughput and cost-effectiveness. |

| Improves Heat Transfer | Creates a solid pathway for heat conduction in the vacuum, ensuring uniform temperature and a complete reaction. |

| Optimizes Process Control | Applying the correct pressure (e.g., 30-40 MPa) is critical for creating consistent, high-quality briquettes. |

Ready to Optimize Your Solid-State Reactions?

Briquetting is a critical step for achieving efficient and high-yield vacuum thermal processes. The right laboratory equipment is essential for success.

KINTEK's expertise can help you:

- Accelerate R&D with reliable lab presses that ensure perfect briquette density and consistency.

- Scale Your Process with robust furnaces and presses designed for high-throughput production.

- Solve Material Challenges by customizing equipment to your specific material mix and reaction goals.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs.

Contact us today to discuss how our solutions can enhance your vacuum reduction efficiency and throughput.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control