To sinter zirconia crowns, you must heat the pre-milled, chalky restoration in a specialized furnace to a precise temperature, typically between 1350°C and 1550°C. This controlled heating process, known as sintering, causes the material to densify and crystallize, transforming it from a fragile state into a hard, durable, and aesthetic final product. The entire cycle involves a gradual heating ramp, a "soak" or dwell period at the target temperature, and a carefully controlled cooling phase.

Sintering is not merely a heating process; it is a fundamental material transformation. Success depends on precisely controlling temperature and time to achieve the desired density, strength, and translucency without introducing internal stresses or defects.

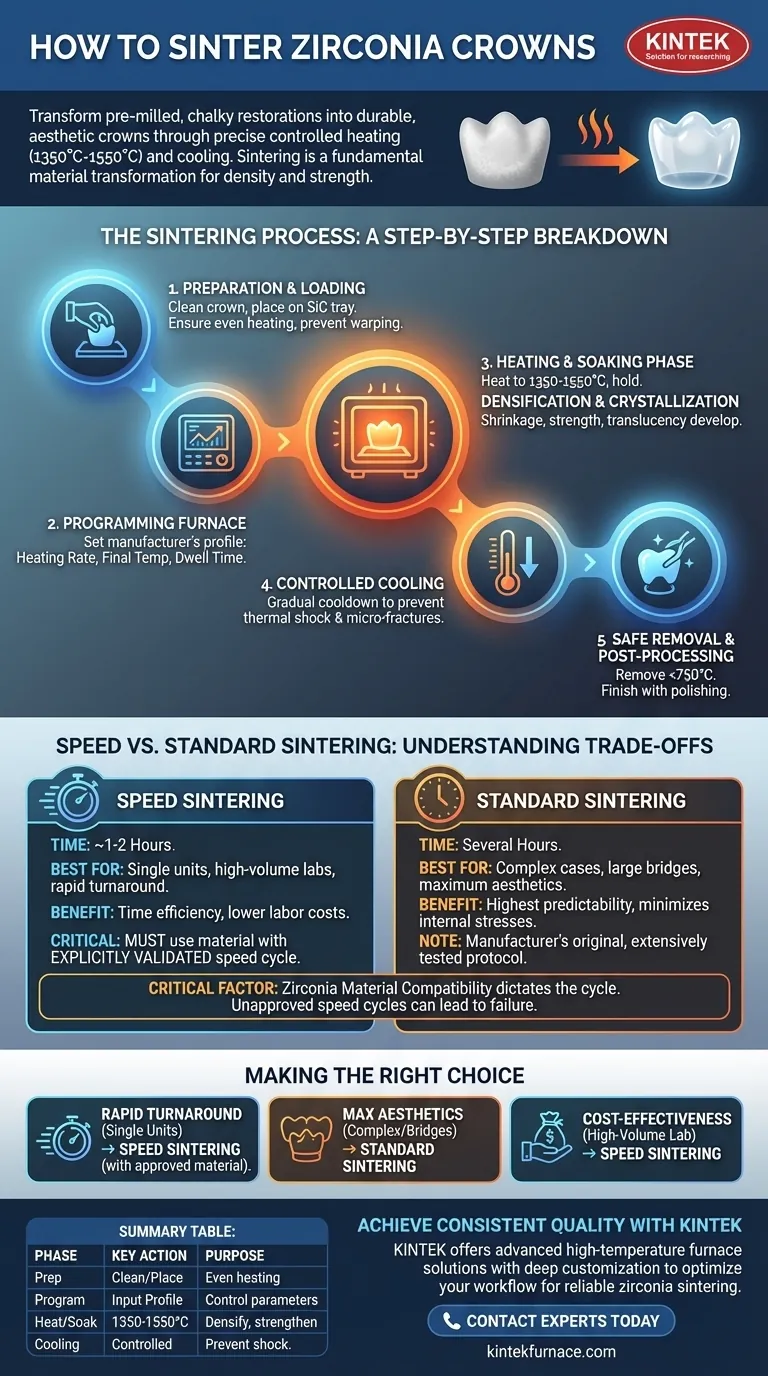

The Sintering Process: A Step-by-Step Breakdown

The journey from a soft, milled blank to a final restoration follows a highly controlled and critical path. Each step is essential for the final clinical success of the crown.

Preparation and Loading

Before the cycle begins, the milled zirconia restoration must be carefully prepared. This involves removing it from the blank, cleaning off any dust, and placing it on a suitable sintering tray, often made of silicon carbide (SiC).

Proper placement ensures even heat distribution and prevents the restoration from warping during the process.

Programming the Furnace

This is the most critical control step. You must program a specific temperature profile based on the zirconia manufacturer's instructions.

Key parameters include the heating rate (how fast the temperature rises), the final sintering temperature, and the dwell time (how long it is held at that peak temperature).

The Heating and Soaking Phase

As the furnace heats up, the zirconia particles begin to fuse. During the "soak" or "dwell" at the peak temperature (e.g., 1550°C), the material undergoes significant densification and crystallization.

This is the phase where the restoration shrinks to its final dimensions and develops its full strength and characteristic translucency.

The Controlled Cooling Phase

Cooling is just as important as heating. The furnace must cool down at a controlled rate to prevent thermal shock, which can cause micro-fractures and compromise the integrity of the restoration.

Rapid, uncontrolled cooling is a primary cause of failures.

Safe Removal and Post-Processing

The restoration should only be removed once the furnace has cooled to a safe temperature, typically below 750°C. Removing it while too hot can induce cracks.

After removal, the crown can be finished with polishing or light machining to achieve the final desired fit and surface texture.

Understanding the Trade-offs: Speed vs. Standard Sintering

Modern dental technology offers a choice between traditional, longer sintering cycles and newer, much faster "speed" cycles. Understanding the differences is key to optimizing your workflow.

The Case for Speed Sintering

Speed sintering cycles can reduce the entire process from many hours to as little as one or two. This offers significant time efficiency, allowing for same-day restorations and reducing labor costs.

Independent research suggests that for specific, compatible zirconia materials, these accelerated cycles can produce restorations with equal or even superior strength compared to traditional methods.

The Inherent Value of Standard Sintering

Standard, longer sintering cycles are the manufacturer's original, extensively tested protocol. They provide the highest degree of predictability, especially for large-span bridges or cases demanding the highest level of aesthetics.

The slower heating and cooling rates minimize internal stresses, which is considered the safest approach for complex or high-value restorations.

The Critical Factor: Zirconia Material Compatibility

The choice between speed and standard sintering is not arbitrary. It is dictated entirely by the specific zirconia material you are using.

Only use a speed cycle if the zirconia manufacturer has explicitly validated it for that material. Using an unapproved cycle can lead to poor aesthetics, reduced strength, and premature clinical failure.

Making the Right Choice for Your Goal

Your decision on which sintering cycle to use should be driven by the clinical demand, the material properties, and your operational priorities.

- If your primary focus is rapid turnaround for single units: Speed sintering is an excellent choice, provided you use a specifically approved zirconia material.

- If your primary focus is maximum aesthetics for complex anterior cases or bridges: A standard, slower sintering cycle is the most reliable and predictable method to ensure optimal results.

- If your primary focus is cost-effectiveness in a high-volume lab: Speed sintering significantly reduces furnace time and labor costs, offering a major competitive advantage.

Ultimately, mastering the sintering process is about matching the right cycle to the specific material and clinical demand to consistently produce strong, reliable restorations.

Summary Table:

| Sintering Phase | Key Action | Purpose |

|---|---|---|

| Preparation | Clean and place crown on SiC tray | Ensure even heating, prevent warping |

| Programming | Input manufacturer's temperature profile | Control heating rate, final temp, dwell time |

| Heating & Soak | Heat to 1350-1550°C and hold | Densify material, achieve strength & translucency |

| Cooling | Controlled cooldown at specified rate | Prevent thermal shock and micro-fractures |

| Cycle Type | Speed Sintering | Standard Sintering |

| Time | ~1-2 hours | Several hours |

| Best For | Single units, high-volume labs, speed | Complex cases (bridges, anteriors), maximum predictability |

Achieve Consistent, High-Quality Zirconia Sintering with KINTEK

Sintering is the most critical step in fabricating a durable, aesthetic zirconia crown. The right furnace is essential for precise temperature control and reliable results, whether you prioritize speed for single-unit cases or maximum predictability for complex bridges.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides dental laboratories with advanced high-temperature furnace solutions. Our product line, including specialized Dental Sintering Furnaces, is complemented by our strong deep customization capability to precisely meet your unique workflow and material requirements.

Let us help you optimize your sintering process. Contact our experts today to discuss your lab's needs and find the perfect furnace solution.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency