Operating a muffle furnace safely and effectively is a matter of following a precise, methodical procedure. The core process involves placing your sample in the chamber, programming the desired temperature and time, allowing the furnace to heat and "soak" at that temperature, and then executing a controlled cooldown before safely removing the sample.

A muffle furnace is a powerful instrument for high-temperature applications, but its power demands respect. The key to successful and safe operation is not speed, but a disciplined process that prioritizes preparation, careful handling, and a controlled cooldown.

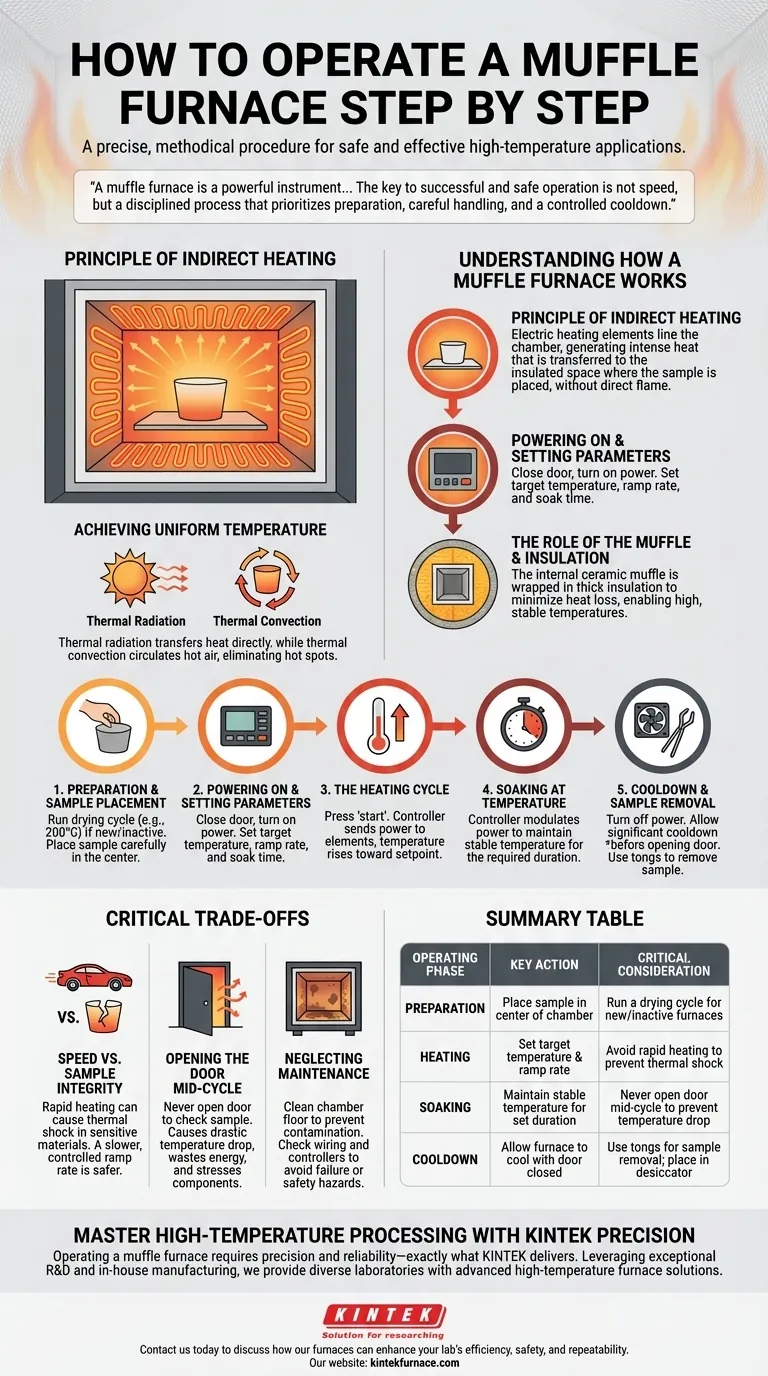

Understanding How a Muffle Furnace Works

To operate the furnace correctly, you must first understand its design. It does not heat your sample directly with a flame.

The Principle of Indirect Heating

A muffle furnace uses electric heating elements, such as nichrome or silicon carbide wires, that line the internal chamber walls. When activated, these elements generate intense heat, which is transferred into the insulated space where the sample is placed.

Achieving Uniform Temperature

The furnace uses two mechanisms to ensure even heating. Thermal radiation transfers heat directly from the hot elements to your sample, while thermal convection circulates the hot air within the chamber. This dual-action process eliminates hot spots and ensures the entire sample reaches a uniform temperature.

The Role of the Muffle and Insulation

The internal chamber, or muffle, is typically made of a high-temperature ceramic. This muffle is wrapped in thick layers of insulation, which minimizes heat loss. This design is what allows the furnace to reach and maintain very high, stable temperatures efficiently.

The Step-by-Step Operating Procedure

Follow these steps for a safe and repeatable outcome. Never deviate from this core process.

Step 1: Preparation and Sample Placement

Before any heating, prepare the furnace. If the furnace is new or has been inactive for a long time, run a drying cycle at a low temperature (e.g., 200°C) for a few hours to remove any absorbed moisture. Once ready, open the furnace door and carefully place your crucible or sample in the center of the chamber.

Step 2: Powering On and Setting Parameters

Close the furnace door securely. Turn on the main power switch. Using the temperature controller, set your target temperature and, if applicable, the desired heating ramp rate and soak time according to your experimental needs.

Step 3: The Heating Cycle

Press the "heat" or "start" button to begin the cycle. The controller will now send power to the heating elements, and the temperature inside the chamber will begin to rise toward your setpoint.

Step 4: Soaking at Temperature

Once the target temperature is reached, the controller will automatically modulate power to the elements. This maintains the temperature with high stability for the duration of your required "soak" time.

Step 5: Cooldown and Sample Removal

After the experiment is complete, turn off the heating elements and the main power switch. Do not open the door immediately. Allow the furnace to cool down significantly. Opening the door while it is hot can cause thermal shock to both the sample and the furnace lining. Once cooled to a safe temperature, use long tongs to carefully remove the hot crucible and place it in a desiccator or on a heat-proof surface to cool to room temperature.

Understanding the Critical Trade-offs

Efficient operation requires understanding the consequences of your choices.

Speed vs. Sample Integrity

While it may be tempting to set a fast ramp rate, this can be destructive. Rapid heating can cause thermal shock in sensitive materials like ceramics or glass, leading to cracks or failure. A slower, more controlled ramp rate is almost always safer.

Opening the Door Mid-Cycle

Never open the furnace door to "check on" a sample unless absolutely necessary. Doing so causes a drastic temperature drop, wastes significant energy, and introduces thermal stress that can shorten the life of the heating elements and furnace insulation.

Neglecting Maintenance

Over time, oxides and residues can build up on the chamber floor. Failing to clean this periodically can lead to contamination of future samples and inhibit efficient heat transfer. Likewise, ignoring wiring or controller checks can lead to equipment failure or a safety hazard.

Making the Right Choice for Your Process

Your specific goal will dictate your focus during operation.

- If your primary focus is ashing or burning off organics: Prioritize a slow initial ramp rate and ensure proper ventilation to handle any fumes or off-gassing from the sample.

- If your primary focus is heat-treating metals: Emphasize the accuracy of the setpoint and the exact duration of the soak time, as these are critical for achieving the desired material properties.

- If your primary focus is materials research: Always run a pre-use drying cycle on the furnace to remove moisture, as this ensures your experimental conditions are as controlled and repeatable as possible.

Mastering the muffle furnace comes from treating it as a precision instrument, where a methodical and patient approach always yields the best results.

Summary Table:

| Operating Phase | Key Action | Critical Consideration |

|---|---|---|

| Preparation | Place sample in center of chamber | Run a drying cycle for new/inactive furnaces |

| Heating | Set target temperature & ramp rate | Avoid rapid heating to prevent thermal shock |

| Soaking | Maintain stable temperature for set duration | Never open door mid-cycle to prevent temperature drop |

| Cooldown | Allow furnace to cool with door closed | Use tongs for sample removal; place in desiccator |

Master High-Temperature Processing with KINTEK Precision

Operating a muffle furnace requires precision and reliability—exactly what KINTEK delivers. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Contact us today (#ContactForm) to discuss how our furnaces can enhance your lab's efficiency, safety, and repeatability.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation