To properly set up your muffle furnace, you must first adjust the temperature controller to the required working temperature and then initiate the heating process, often by pressing a "start" or "heating" button. You can confirm the furnace is operating correctly by checking for an ammeter reading (if available) and observing a gradual, steady increase on the temperature display.

Setting a muffle furnace controller is more than just inputting a final temperature. It is a deliberate process of programming your desired thermal cycle and verifying that the entire system is responding safely and accurately before you commit to your experiment.

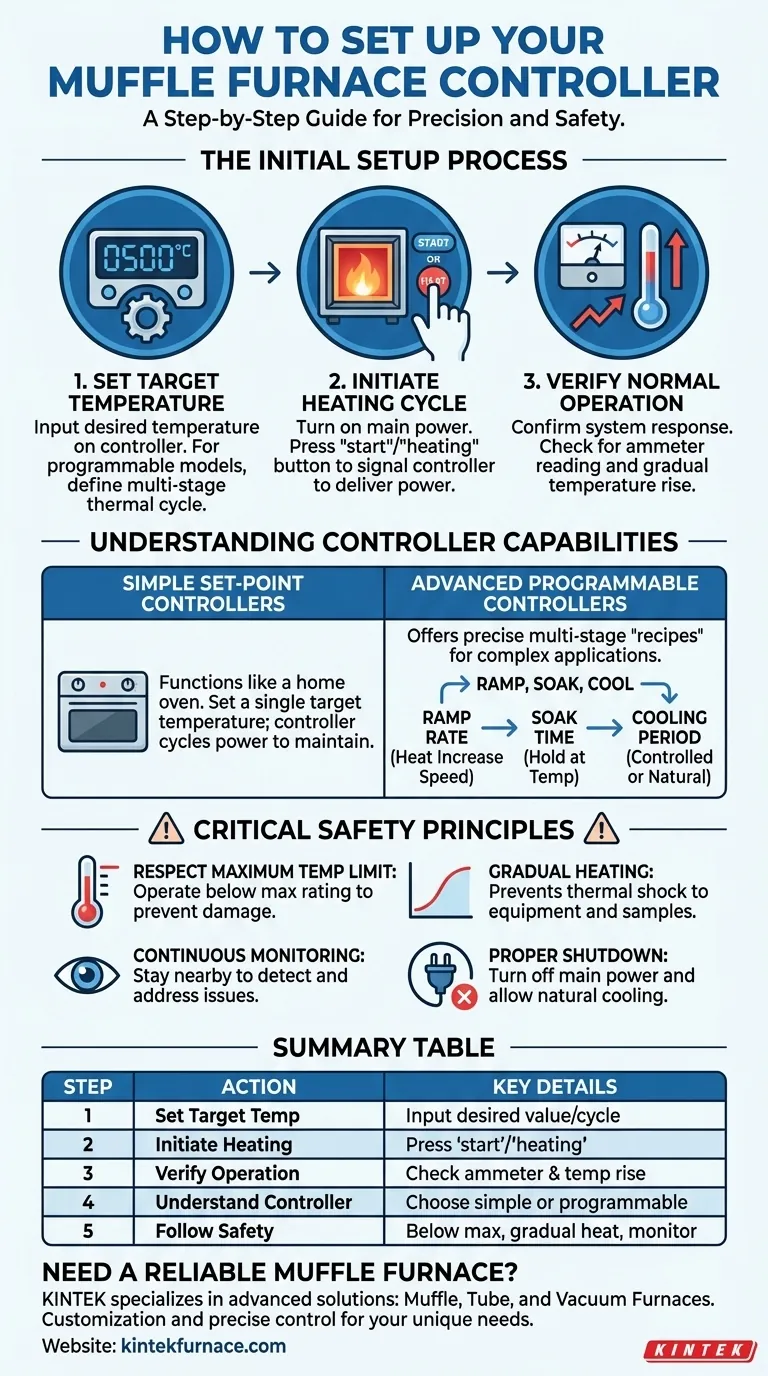

The Initial Setup and Verification Process

Proper setup is a two-part process: commanding the furnace and then confirming it has obeyed that command correctly.

Step 1: Set the Target Temperature

Before powering the heating elements, the first step is always to input your desired temperature into the temperature controller. This sets the target for the system.

On simpler models, this may be a single value. On advanced controllers, this could be the first step in a multi-stage program.

Step 2: Initiate the Heating Cycle

With your sample loaded and the door closed, turn on the main power switch. You will then need to press a "heating" or "start" button to begin the process.

This action signals the controller to begin delivering power to the heating elements.

Step 3: Verify Normal Operation

Do not walk away immediately. A critical step is to confirm the furnace is working as expected.

Look for two key indicators: the ammeter should show a reading, confirming power is flowing to the elements, and the temperature display should begin to rise steadily. This simple check prevents wasting time on a faulty unit or a missed step.

Understanding Your Controller's Capabilities

Not all temperature controllers are the same. The type of controller dictates how you program your heating cycle.

Simple Set-Point Controllers

The most basic controllers function like a home oven. You set a single target temperature, and the furnace heats up until it reaches that point.

The controller will then cycle the power on and off to maintain that temperature, a process known as "hunting."

Advanced Programmable Controllers

Modern furnaces are often equipped with programmable controllers that offer precise control over the entire thermal profile.

These allow you to define a multi-stage "recipe" for your process, ensuring accuracy and reproducibility for complex applications.

The Importance of Ramp, Soak, and Cool

Programmable controllers allow you to define specific heating cycles:

- Ramp Rate: How quickly the temperature increases (e.g., 10°C per minute).

- Soak Time: How long the furnace holds at a specific temperature.

- Cooling Period: A controlled or natural cooling phase.

This level of control is essential for materials that are sensitive to thermal shock or require precise heat treatment.

Critical Principles for Safe Operation

Misusing a muffle furnace can damage the equipment and create significant safety hazards. Following these principles is essential for protecting both your investment and your lab personnel.

Respect the Maximum Temperature Limit

Every furnace has a maximum rated temperature. Exceeding this limit, even for a short time, can cause permanent damage to the heating elements and refractory insulation.

Always operate slightly below the maximum temperature to ensure a longer service life for the furnace.

The Value of Gradual Heating

Unless your process requires rapid heating, a gradual increase in temperature is always safer for the equipment.

For some systems, this may involve manually increasing the voltage in stages. For programmable controllers, it means setting a conservative ramp rate. This prevents thermal shock to both the furnace components and your sample.

Continuous Monitoring is Non-Negotiable

Even with modern automatic controls, failure is always a possibility. A malfunctioning controller could lead to a thermal runaway event, burning out the furnace wires.

Always remain in the vicinity of an operating furnace to monitor its progress and intervene in case of an emergency.

The Shutdown Procedure

Proper shutdown protects the furnace. After the experiment, turn off the main power and allow the furnace to cool naturally.

Keep the door closed during cooldown to prevent ambient moisture from entering and corroding the furnace chamber.

Making the Right Choice for Your Process

Your setup procedure should be guided by your specific experimental goal.

- If your primary focus is a simple, single-temperature bake: Set your target temperature, initiate heating, and verify the system is responding before leaving it to soak.

- If your primary focus is a complex thermal treatment: Use a programmable controller to meticulously define each ramp rate and soak time required by your material.

- If your primary focus is equipment safety and longevity: Always operate below the maximum rated temperature, use gradual heating ramps, and monitor the furnace throughout its operation.

Ultimately, mastering your muffle furnace comes from treating it as a precision instrument, not just a simple oven.

Summary Table:

| Step | Action | Key Details |

|---|---|---|

| 1 | Set Target Temperature | Input desired temperature; may be single value or part of multi-stage program. |

| 2 | Initiate Heating Cycle | Press 'start' or 'heating' button after turning on main power. |

| 3 | Verify Normal Operation | Check ammeter reading and steady temperature rise to confirm system response. |

| 4 | Understand Controller Type | Use simple set-point for basic needs or programmable for ramp/soak/cool cycles. |

| 5 | Follow Safety Principles | Operate below max temperature, use gradual heating, and monitor continuously. |

Need a reliable muffle furnace for your lab? KINTEK specializes in advanced high-temperature solutions, including Muffle, Tube, and Vacuum Furnaces, with deep customization to meet your unique experimental needs. Our expertise ensures precise temperature control and enhanced safety for materials testing. Contact us today to discuss how we can optimize your thermal processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure