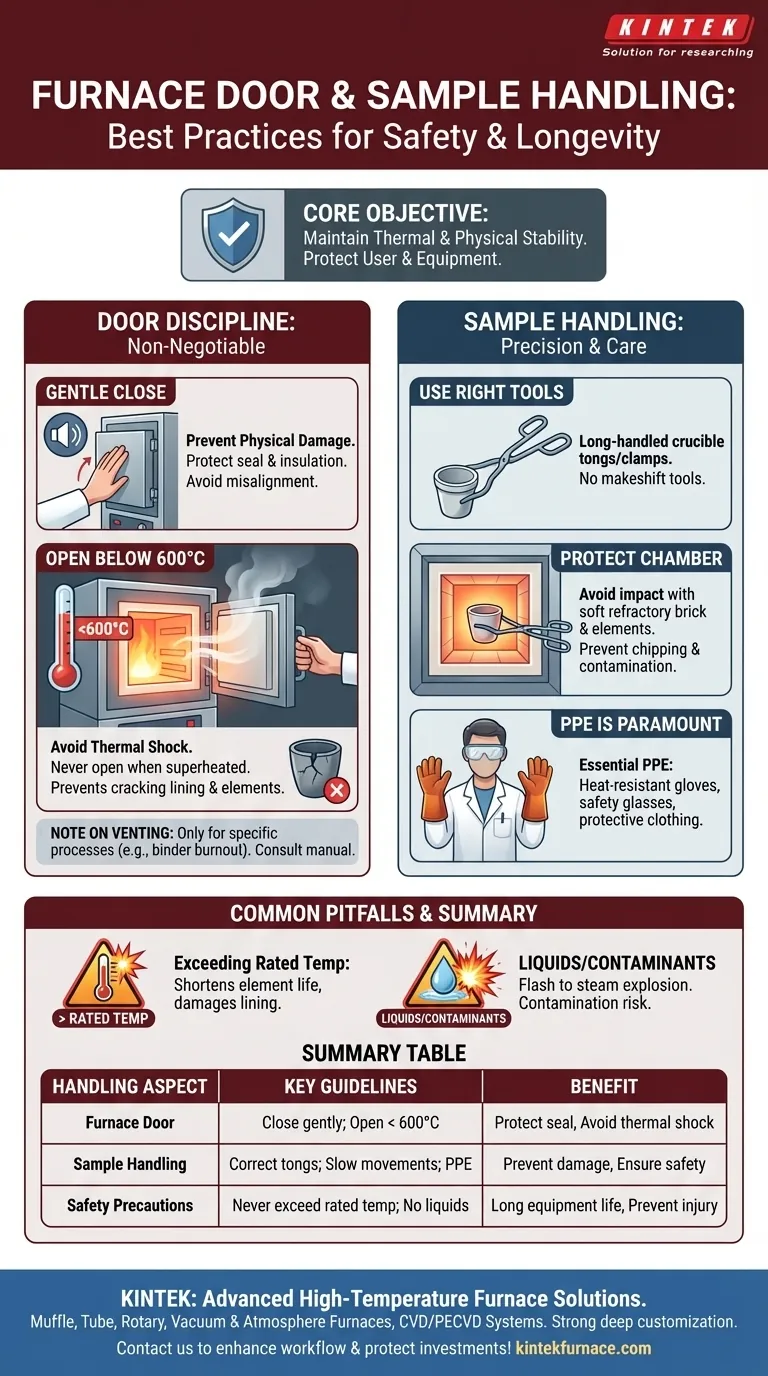

At all times, handle the furnace door and samples with deliberate, gentle care. Close the furnace door softly to protect its seal and structure, and only open it once the internal temperature has naturally cooled below 600°C. When moving samples, use the correct crucible tongs or clamps with slow, steady movements to prevent damaging the fragile furnace interior and ensure your own safety.

Your core objective when operating a high-temperature furnace is to maintain thermal and physical stability. Every action, from closing the door to retrieving a sample, must be performed in a way that protects both the user from extreme heat and the equipment from catastrophic damage.

Why Door Discipline is Non-Negotiable

The furnace door is a critical component for both safety and performance. Mishandling it is one of the fastest ways to cause expensive damage or create an unsafe operating condition.

Preventing Physical Damage

The furnace door and its surrounding seal are precisely engineered. Slamming the door can cause misalignment, damage the refractory insulation, and break the seal, leading to heat loss and inaccurate temperatures.

Always close the door gently until it latches securely.

Avoiding Thermal Shock

The most critical rule is to never open the furnace door when the temperature is above 600°C. A sudden rush of cool, ambient air into a superheated chamber creates immense thermal stress.

This can instantly crack the ceramic furnace lining, damage the heating elements, or even shatter your sample. Always allow the furnace to cool naturally below this threshold before opening.

A Note on Venting

Some instructions mention "opening the door slightly" during a cycle. This typically refers to a specific, controlled venting procedure for processes like binder burnout, where fumes must be allowed to escape.

This is an exception, not the general rule. For standard heating, the door should remain fully closed to maintain temperature stability and efficiency. Always consult your furnace's specific manual for venting protocols.

Handling Samples with Precision and Care

Moving samples into and out of a hot furnace is a high-risk activity. The goal is to perform the task safely and without damaging the furnace's delicate interior.

The Right Tools for the Job

Always use long-handled crucible tongs or clamps designed for high-temperature work. These tools keep your hands at a safe distance from the intense radiant heat.

Makeshift tools are not an option. They can fail, dropping the sample and potentially causing injury or damage.

Protecting the Furnace Chamber

The furnace's internal chamber is lined with soft, brittle refractory brick or ceramic fiber. This material is an excellent insulator but is easily damaged.

When placing or retrieving a sample, guide the tongs carefully to avoid hitting the chamber walls, floor, or heating elements. A careless impact can chip the lining, leading to contamination and costly repairs.

Your Personal Safety is Paramount

Before handling any samples near the furnace, you must be wearing the proper Personal Protective Equipment (PPE). This is not optional.

Essential PPE includes heat-resistant gloves, safety glasses or goggles, and protective lab clothing. This equipment is your only defense against severe burns from radiant heat or accidental contact.

Understanding the Trade-offs and Pitfalls

Shortcuts in furnace operation almost always lead to equipment failure or safety incidents. Understanding these common mistakes is key to developing good lab discipline.

Pitfall: Exceeding the Rated Temperature

Pushing the furnace beyond its maximum rated temperature to speed up a process is a false economy. It drastically shortens the life of the heating elements and can cause permanent damage to the furnace lining.

Pitfall: Introducing Liquids or Contaminants

Never pour any liquid directly into the furnace chamber. The liquid will flash into steam, creating a pressure explosion that can damage the furnace and cause serious injury. Molten metals should also only be handled in appropriate, contained crucibles.

Always keep the chamber clean to prevent cross-contamination between samples.

Making the Right Choice for Your Goal

Adhering to correct procedure ensures safety, protects your investment, and guarantees the integrity of your work.

- If your primary focus is equipment longevity: Always close the door gently and never operate the furnace above its maximum rated temperature.

- If your primary focus is personal safety: Never open the door above 600°C and always wear the full range of required PPE when handling samples.

- If your primary focus is sample integrity: Avoid thermal shock by waiting for the furnace to cool, and keep the chamber meticulously clean to prevent contamination.

Mastering these procedures transforms the furnace from a potential hazard into a reliable and powerful tool for your work.

Summary Table:

| Handling Aspect | Key Guidelines |

|---|---|

| Furnace Door | Close gently to protect seal; open only below 600°C to avoid thermal shock. |

| Sample Handling | Use correct tongs with slow movements; wear heat-resistant gloves and safety glasses. |

| Safety Precautions | Never exceed rated temperature; avoid liquids and contaminants in chamber. |

Ensure your lab operates safely and efficiently with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our products can enhance your workflow and protect your investments!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control