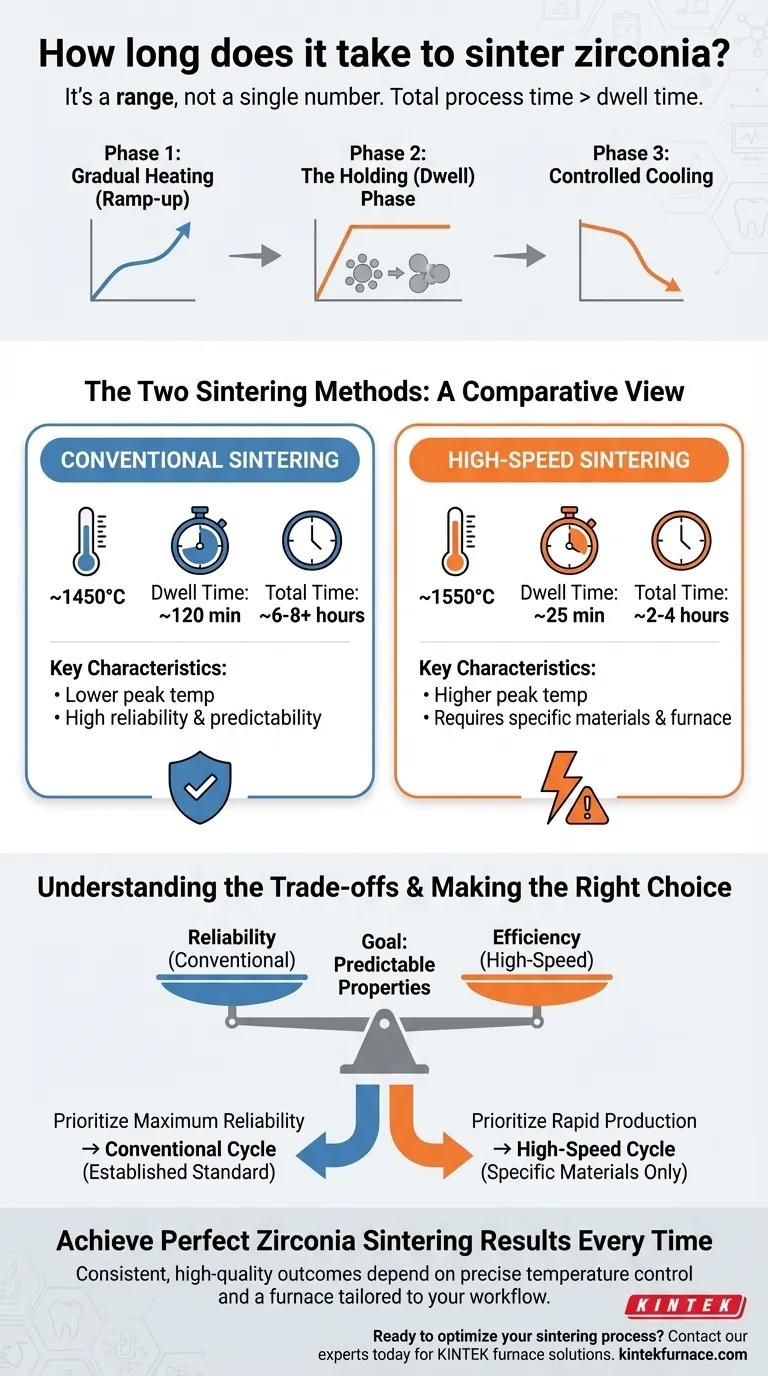

The duration of a full zirconia sintering cycle is not a single number, but a range typically spanning several hours. While the critical "holding" or "dwell" time at peak temperature can be as short as 25 minutes for high-speed methods or as long as 120 minutes for conventional cycles, the total process time including heating and cooling is significantly longer.

The total time required to sinter zirconia is dictated by the specific sintering protocol—conventional or high-speed—which in turn depends on the type of zirconia and the desired physical properties of the final restoration.

The Anatomy of a Sintering Cycle

Sintering is more than just baking; it is a precisely controlled thermal process that transforms the chalky, pre-sintered zirconia into a dense, strong, and translucent ceramic. The total time is a sum of its distinct phases.

Phase 1: Gradual Heating

The furnace does not immediately jump to its target temperature. It must heat up gradually to prevent thermal shock, which could cause cracks in the restoration. This ramp-up phase is a significant portion of the total cycle time.

Phase 2: The Holding (Dwell) Phase

This is the most critical phase, where the furnace maintains a peak temperature, typically between 1350°C and 1550°C. During this "soaking" period, the zirconia particles fuse together, the material densifies, and it gains its final strength and translucency. The length of this phase is the primary difference between sintering methods.

Phase 3: Controlled Cooling

Just as with heating, cooling must be slow and controlled. Rapid cooling can introduce internal stresses and compromise the structural integrity of the zirconia. This cooling phase also adds considerable time to the overall process.

Key Factors Determining Sintering Time

The wide variation in sintering times comes down to a choice between two primary methodologies, each designed for different clinical and laboratory needs.

Conventional Sintering

This is the traditional, well-established method. It typically involves a lower peak temperature (around 1450°C) and a longer holding time of approximately 120 minutes (2 hours). The entire cycle, including heating and cooling, often takes several hours to complete.

High-Speed Sintering

To meet demands for faster turnaround, high-speed sintering protocols were developed. These cycles use a higher peak temperature (around 1550°C) to achieve densification with a much shorter holding time, often as little as 25 minutes. This requires specific zirconia materials and furnaces designed to handle the rapid thermal changes.

Understanding the Trade-offs

Choosing a sintering cycle is not just about saving time; it's about achieving a specific, predictable outcome. Speed and quality are often in a delicate balance.

The Goal: Predictable Properties

The purpose of any sintering cycle is to achieve the exact physical properties—strength, durability, and aesthetics—that the manufacturer intended. Deviating from the recommended protocol puts these properties at risk.

Conventional Method: Reliability

The longer, slower conventional cycle is known for its high reliability and predictability. It is the benchmark against which newer, faster methods are measured, ensuring complete and uniform densification.

High-Speed Method: Efficiency with Caveats

High-speed sintering offers a dramatic increase in efficiency. However, it is not a universal solution. It must be performed using zirconia materials specifically formulated for rapid firing and in a furnace validated for the high-speed cycle. Using the wrong material or furnace can result in a compromised restoration.

Making the Right Choice for Your Goal

The correct cycle is the one that is validated for the specific zirconia material you are using. Always prioritize the manufacturer's instructions.

- If your primary focus is maximum reliability and proven outcomes: Adhere to the conventional, longer sintering cycle, as it is the established standard for achieving optimal material properties.

- If your primary focus is rapid production and chair-side service: Utilize a high-speed sintering cycle, but only with zirconia materials and furnace programs that are explicitly designed and approved for this process.

Ultimately, consistent and high-quality results are achieved by precisely following the validated instructions for your specific material and equipment.

Summary Table:

| Sintering Method | Typical Dwell Time | Total Cycle Time (Approx.) | Key Characteristics |

|---|---|---|---|

| Conventional | ~120 minutes | 6-8+ hours | Lower peak temperature (~1450°C); high reliability and predictability. |

| High-Speed | ~25 minutes | 2-4 hours | Higher peak temperature (~1550°C); requires specific zirconia and furnace. |

Achieve Perfect Zirconia Sintering Results Every Time

Consistent, high-quality outcomes depend on precise temperature control and a furnace tailored to your specific materials and workflow. KINTEK understands the critical balance between speed and reliability in the dental lab.

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capability to precisely meet your unique sintering requirements—whether you prioritize the proven reliability of conventional cycles or the efficiency of high-speed protocols.

Ready to optimize your sintering process? Contact our experts today to discuss how a KINTEK furnace can deliver the precision, consistency, and performance your lab demands.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time