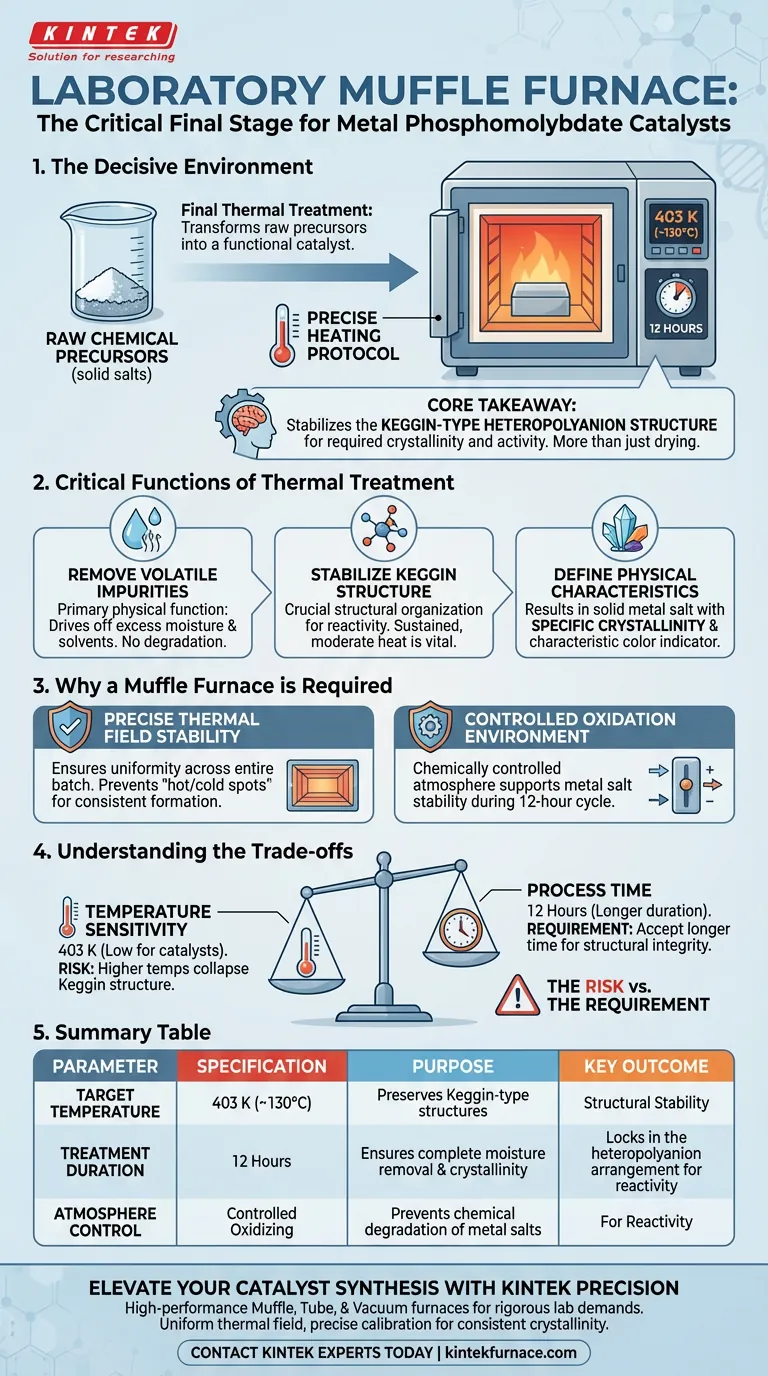

A laboratory muffle furnace serves as the decisive environment for the final thermal treatment of metal phosphomolybdate catalysts. Specifically, it is used to subject solid salts derived from chemical reactions to a precise heating protocol, typically maintained at 403 K (approximately 130°C) for 12 hours. This controlled thermal exposure is the mechanism that transforms raw chemical precursors into a stable, functional catalyst.

Core Takeaway The muffle furnace does more than simply dry the material; it acts as a structural stabilizer. By maintaining a strict temperature profile, it drives off excess moisture while simultaneously locking in the Keggin-type heteropolyanion structure, ensuring the catalyst achieves the necessary crystallinity and chemical activity.

The Critical Functions of Thermal Treatment

Removing Volatile Impurities

The primary physical function of the furnace during this stage is the removal of solvents.

The raw solid salts obtained from initial chemical reactions often retain significant amounts of moisture or solvent residues.

Heating the material effectively drives off this excess moisture without degrading the chemical components.

Stabilizing the Keggin Structure

Beyond simple drying, the thermal energy provided by the furnace initiates a crucial structural organization.

For metal phosphomolybdate catalysts, the goal is to stabilize the Keggin-type heteropolyanion structure.

This specific molecular arrangement is vital for the catalyst's reactivity, and it requires sustained, moderate heat to form correctly.

Defining Physical Characteristics

The furnace treatment is directly responsible for the final physical appearance and quality of the solid.

Successful treatment results in a solid metal salt catalyst with specific crystallinity.

It also produces a characteristic coloration, which serves as a visual indicator that the correct chemical phase has been achieved.

Why a Muffle Furnace is Required

Precise Thermal Field Stability

Consistency is paramount when preparing chemical catalysts.

A laboratory muffle furnace provides excellent thermal field stability, ensuring the entire batch receives the exact same heat exposure.

This uniformity prevents "hot spots" or "cold spots" that could lead to uneven drying or inconsistent structural formation.

Controlled Oxidation Environment

While the primary reference highlights a 403 K treatment, muffle furnaces are generally capable of creating specific oxidizing environments.

This capability ensures that the transition from precursor to active catalyst happens in a chemically controlled atmosphere.

This environment supports the stability of the metal salts throughout the 12-hour treatment cycle.

Understanding the Trade-offs

Temperature Sensitivity vs. Process Time

The specific protocol for metal phosphomolybdate—403 K for 12 hours—reveals a specific trade-off.

This temperature is relatively low compared to the high-temperature sintering (900°C+) used for other catalyst types.

The risk: Increasing the temperature to speed up the process can collapse the delicate Keggin structure.

The requirement: You must accept a longer processing time (12 hours) to preserve the structural integrity of this specific heteropolyanion.

Equipment Calibration Dependencies

The quality of the final catalyst is heavily dependent on the furnace's calibration.

If the furnace's internal thermocouple is inaccurate, the actual chamber temperature may deviate from the setpoint.

Even a slight deviation could fail to fully stabilize the crystal structure or, conversely, degrade the active sites.

Making the Right Choice for Your Goal

To ensure the successful preparation of metal phosphomolybdate catalysts, consider the following based on your specific objectives:

- If your primary focus is Structural Integrity: Adhere strictly to the 403 K limit to preserve the Keggin-type structure, avoiding the temptation to accelerate drying with higher heat.

- If your primary focus is Batch Consistency: Verify the thermal uniformity of your muffle furnace to ensure that the characteristic coloration and crystallinity are identical across the entire sample volume.

Precision in this final thermal stage is the difference between a raw chemical salt and a high-performance catalyst.

Summary Table:

| Parameter | Specification | Purpose |

|---|---|---|

| Target Temperature | 403 K (approx. 130°C) | Preserves delicate Keggin-type structures |

| Treatment Duration | 12 Hours | Ensures complete moisture removal and crystallinity |

| Atmosphere Control | Controlled Oxidizing | Prevents chemical degradation of metal salts |

| Key Outcome | Structural Stability | Locks in the heteropolyanion arrangement for reactivity |

Elevate Your Catalyst Synthesis with KINTEK Precision

Don't let thermal fluctuations compromise your delicate Keggin structures. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum furnace systems designed for the rigorous demands of laboratory research. Our customizable high-temp solutions provide the uniform thermal field and precise calibration necessary to ensure consistent crystallinity and catalytic activity for your unique needs.

Ready to optimize your thermal processing? Contact KINTEK Experts Today

Visual Guide

References

- Metal Phosphomolybdate-Catalyzed Condensation of Furfural with Glycerol. DOI: 10.3390/pr13082665

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is the furnace atmosphere important in a muffle furnace? Unlock Precise Material Control

- What is a box type furnace? A Versatile Tool for High-Temperature Batch Processing

- What is the primary purpose of using a muffle furnace for MAL calcination? Unlock the Structure Memory Effect

- What is the function of a box-type resistance furnace in GFRP studies? Mastering High-Temperature Material Simulation

- Why are muffle furnaces popular in industrial sectors? Discover Their Key Benefits for Clean, Precise Heating

- What are the advantages of the bottom-loading furnace configuration? Achieve High-Temp Control and Element Protection

- How do vacuum muffle furnaces combine the benefits of tube and muffle furnaces? Achieve High Throughput with Purity

- What maintenance checks are required for a muffle furnace? Ensure Safety and Accuracy in Your Lab