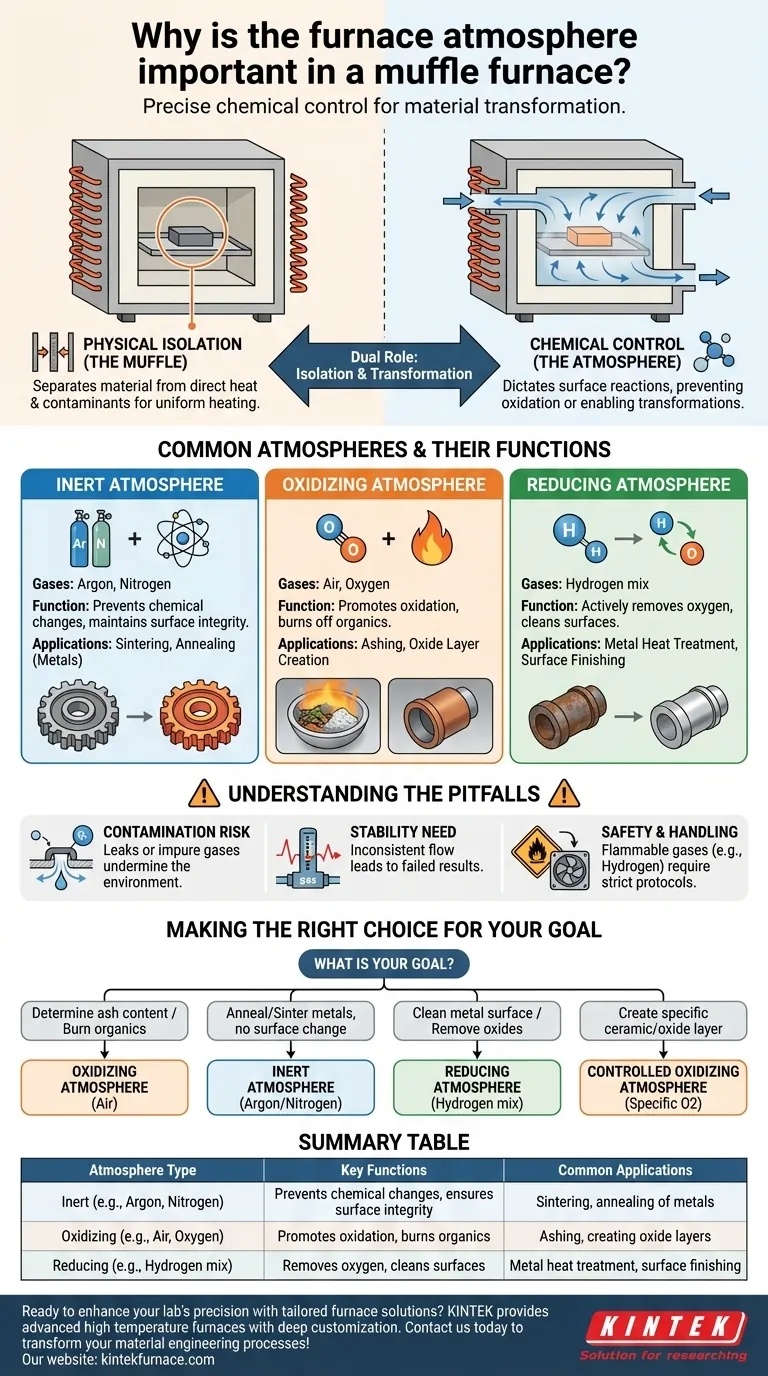

The atmosphere in a muffle furnace is critical because it provides precise chemical control over your material during heat treatment. While the furnace's muffle physically isolates the sample from heating elements and contaminants, the introduced atmosphere dictates the chemical reactions that occur on the material's surface, preventing undesirable outcomes like oxidation and enabling specific transformations.

The core function of a muffle is physical isolation for clean, uniform heating. The purpose of atmosphere control is to move beyond simple heating and create a specific chemical environment required to intentionally transform your material or protect it from unwanted reactions.

The Dual Role: Isolation and Transformation

A muffle furnace performs two distinct but complementary functions. Understanding both is key to achieving reliable and repeatable results in your work.

Physical Isolation: The Muffle's Purpose

The term "muffle" refers to the chamber that encloses your sample. Its primary job is to create a physical barrier.

This barrier separates the material from the direct heat source (like flames or electric elements) and any byproducts of combustion. This ensures heating is uniform and prevents external contamination.

Chemical Control: The Atmosphere's Function

While the muffle provides a clean slate, the gas atmosphere you introduce determines the chemical outcome. Without this control, heating a material in ambient air would almost always lead to oxidation.

By displacing the air with a specific gas or gas mixture, you can create a controlled chemical environment. This allows you to either prevent all reactions or intentionally promote a specific one.

Common Atmospheres and Their Functions

The choice of atmosphere directly depends on the goal of your heat treatment process. Different gases serve entirely different purposes.

Inert Atmosphere

An inert atmosphere, typically using gases like Argon or Nitrogen, is designed to be non-reactive.

Its purpose is to prevent any chemical changes on the material's surface. This is ideal for processes like sintering or annealing where you only want to change the material's physical structure through heat, not its chemistry.

Oxidizing Atmosphere

An oxidizing atmosphere contains an excess of oxygen, often by using simple air or introducing pure oxygen.

This environment is used to intentionally promote oxidation. It is essential for processes like ashing, where the goal is to completely burn away organic components to measure the inorganic residue, or for creating specific oxide layers on a material.

Reducing Atmosphere

A reducing atmosphere actively removes oxygen. It is typically a mixture containing hydrogen, which reacts with and removes oxygen from the furnace chamber and the material's surface.

This is critical for the heat treatment of many metals. It not only prevents the formation of new oxides but can also remove existing oxide layers, resulting in a clean, bright surface finish.

Understanding the Pitfalls

Precise atmosphere control is powerful but requires careful management. A failure to control the environment properly can easily compromise your experiment.

The Risk of Contamination

The integrity of your atmosphere is paramount. Leaks in the furnace seals or the use of impure gases can introduce oxygen or moisture, undermining the purpose of an inert or reducing environment.

The Need for Stability

The atmosphere must be stable throughout the entire heating and cooling cycle. Any fluctuations in gas flow, managed by a gas flow meter, can alter the chemical balance inside the chamber and lead to inconsistent or failed results.

Safety and Gas Handling

Certain atmospheres, particularly reducing atmospheres containing hydrogen, are flammable. Proper safety protocols, ventilation, and handling procedures are non-negotiable when working with these gases.

Making the Right Choice for Your Goal

The correct atmosphere is dictated entirely by your desired outcome. Use the following guidelines to make a decision.

- If your primary focus is determining ash content or burning off organics: Use a standard oxidizing atmosphere (air) to ensure complete combustion.

- If your primary focus is annealing or sintering metals without surface change: Use an inert atmosphere (Argon, Nitrogen) or a reducing atmosphere to prevent oxidation.

- If your primary focus is cleaning the surface of a metal part: Use a reducing atmosphere (Hydrogen/Nitrogen mix) to actively remove surface oxides.

- If your primary focus is creating a specific ceramic or oxide layer: Use a carefully controlled oxidizing atmosphere with a specific oxygen concentration.

Mastering the furnace atmosphere is the key to moving from simple heating to precise material engineering.

Summary Table:

| Atmosphere Type | Key Functions | Common Applications |

|---|---|---|

| Inert (e.g., Argon, Nitrogen) | Prevents chemical changes, ensures surface integrity | Sintering, annealing of metals |

| Oxidizing (e.g., Air, Oxygen) | Promotes oxidation, burns organics | Ashing, creating oxide layers |

| Reducing (e.g., Hydrogen mix) | Removes oxygen, cleans surfaces | Metal heat treatment, surface finishing |

Ready to enhance your lab's precision with tailored furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met with reliability and efficiency. Contact us today to discuss how our solutions can transform your material engineering processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing