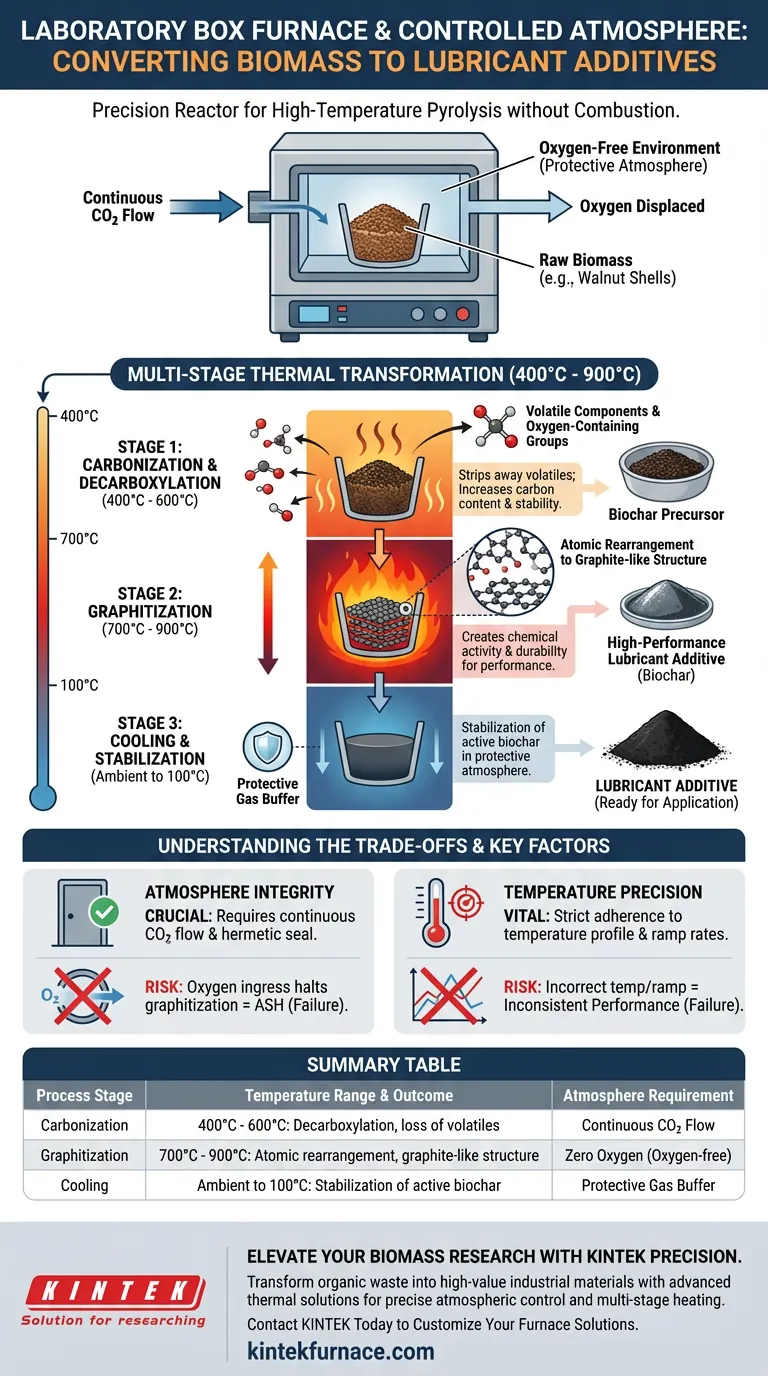

A laboratory box furnace with a controlled atmosphere functions as a precision reactor for converting biomass into lubricant additives. It utilizes a protective gas flow to enable high-temperature pyrolysis without combustion, transforming raw organic material into chemically active biochar.

By maintaining a continuous flow of carbon dioxide and executing multi-stage heating between 400°C and 900°C, the furnace systematically alters the biomass structure. This process drives carbonization and graphitization, resulting in a stable, high-performance additive suitable for lubrication applications.

Creating the Essential Processing Environment

The Function of Protective Atmosphere

To convert biomass—such as walnut shells—into a lubricant additive, you must prevent the material from simply burning to ash.

The atmosphere furnace solves this by introducing a continuous flow of carbon dioxide. This displaces oxygen, creating an oxygen-free or oxygen-limited environment essential for pyrolysis.

Enabling Chemical Transformation

In this controlled environment, the biomass undergoes thermal decomposition rather than combustion.

The furnace acts as a hermetically sealed chamber where the chemical structure of the biomass can be fundamentally altered without the destructive interference of oxidation.

The Multi-Stage Thermal Transformation

Precise Temperature Control

The furnace allows for complex, multi-stage heating protocols across a critical range of 400°C to 900°C.

This wide range is necessary because different chemical reactions occur at specific thermal thresholds, requiring the furnace to hold exact temperatures for set durations.

Carbonization and Decarboxylation

At the lower to mid-range temperatures, the furnace facilitates carbonization and decarboxylation.

These processes strip away volatile components and oxygen-containing groups from the biomass structure. This increases the carbon content and stability of the material, which is the first step toward creating a functional additive.

Graphitization for Performance

As the furnace reaches higher temperatures (approaching 900°C), the material undergoes graphitization.

This rearranges the carbon atoms into a more ordered, graphite-like structure. This specific crystalline arrangement provides the necessary chemical activity and durability required for high-performance lubricant additives.

Understanding the Trade-offs

Atmosphere Integrity vs. Oxidation risk

The success of this process relies entirely on the integrity of the gas seal and flow.

If the carbon dioxide flow is interrupted or the seal is breached, oxygen will enter the chamber. This instantly halts the graphitization process and ruins the sample by turning the valuable biochar into useless ash.

Temperature Precision vs. Material Quality

Achieving the correct degree of graphitization requires strict adherence to the temperature profile.

If the furnace fails to reach the upper limits (900°C), the biomass will not graphitize sufficiently to function as a lubricant. Conversely, incorrect ramp rates can cause thermal shock or uneven heating, leading to inconsistent additive performance.

Making the Right Choice for Your Goal

To maximize the effectiveness of a laboratory box furnace for this application:

- If your primary focus is graphitization quality: Prioritize a furnace capable of sustaining the upper temperature range (900°C) with high uniformity to ensure maximum structural ordering of carbon.

- If your primary focus is process consistency: Ensure the furnace has a robust gas flow management system to maintain a flawless carbon dioxide atmosphere throughout the multi-stage cycle.

The precise control of atmosphere and heat is the difference between burning waste and engineering a high-value industrial material.

Summary Table:

| Process Stage | Temperature Range | Chemical Outcome | Atmosphere Requirement |

|---|---|---|---|

| Carbonization | 400°C - 600°C | Decarboxylation & loss of volatiles | Continuous CO2 Flow |

| Graphitization | 700°C - 900°C | Atomic rearrangement to graphite-like structure | Zero Oxygen (Oxygen-free) |

| Cooling | Ambient to 100°C | Stabilization of active biochar | Protective Gas Buffer |

Elevate Your Biomass Research with KINTEK Precision

Transform organic waste into high-value industrial materials with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems specifically designed for precise atmospheric control and multi-stage heating.

Whether you need to optimize graphitization or ensure a flawless carbon dioxide seal, our customizable lab furnaces provide the uniformity and reliability your research demands. Don't let oxidation ruin your samples—partner with the high-temp furnace experts.

Contact KINTEK Today to Customize Your Furnace Solutions

Visual Guide

References

- Influence of a Walnut Shell Biochar Additive on the Tribological and Rheological Properties of Vegetable Lubricating Grease. DOI: 10.3390/lubricants13050213

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What level of temperature stability can be achieved with an experimental box type atmosphere furnace? Achieve ±1°C Precision for Reliable Results

- What is the primary purpose of using a constant temperature drying oven in sugarcane bagasse pretreatment? Find Out Why

- What types of metal heat treatments can be performed using a box type annealing atmosphere furnace? Discover Annealing and Brazing Solutions

- How are retort furnaces utilized in laboratory settings? Essential for Controlled Atmosphere Thermal Processes

- How does a horizontal box furnace facilitate atmosphere control in the synthesis of Ni-TiON catalysts?

- How do industrial vacuum or atmosphere furnaces improve Inconel 718 after WAAM? Optimize Strength and Microstructure

- Why are high-temperature vacuum or atmosphere furnaces used for annealing metal silicide? Unlock Peak Thermal Stability

- What are the advantages of an atmosphere protection box furnace? Achieve Scale-Free, High-Precision Metal Annealing