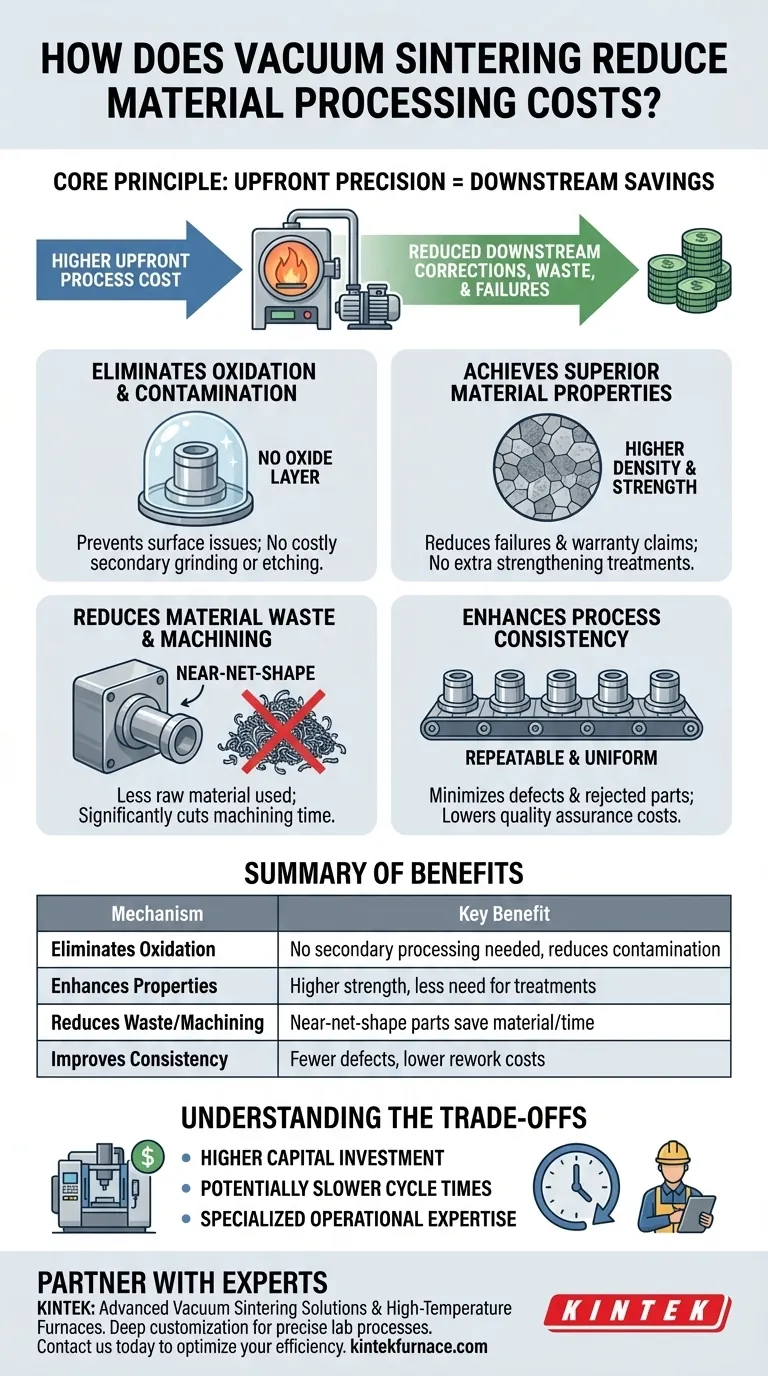

At its core, vacuum sintering reduces manufacturing costs by creating superior, near-net-shape parts that require fewer secondary processing steps. By eliminating atmospheric gases, the process prevents oxidation and contamination, leading to higher material strength and significantly less waste, which directly translates to lower overall production expenses.

The fundamental cost-saving principle of vacuum sintering is a shift in investment: it incurs a higher upfront process cost to drastically reduce or eliminate expensive downstream corrections, material waste, and product failures.

The Core Mechanisms of Cost Reduction

To understand the financial benefits, you must first understand the technical advantages that vacuum sintering provides over traditional atmospheric methods. Each advantage directly mitigates a common source of manufacturing cost.

Eliminating Oxidation and Contamination

In a conventional furnace, the presence of oxygen and other atmospheric gases causes an undesirable oxide layer to form on the material's surface, especially at high sintering temperatures.

Removing this layer requires costly and time-consuming secondary processes like grinding, chemical etching, or machining. Vacuum sintering removes the atmosphere, preventing oxidation from occurring in the first place and delivering a clean part directly from the furnace.

This is especially critical for reactive materials like titanium or certain specialty steels, where even trace amounts of oxygen can compromise the material's structural integrity, leading to scrapped parts.

Achieving Superior Material Properties

The vacuum environment allows materials to be heated to higher temperatures without the risk of vaporization that would occur at normal atmospheric pressure.

This enables a more complete densification process, resulting in parts with higher density, superior strength, and greater wear resistance. A stronger, more durable final product reduces long-term costs associated with warranty claims, replacements, and field failures.

Furthermore, because the inherent properties are superior, expensive secondary strengthening treatments like case hardening or coating may become unnecessary.

Reducing Material Waste and Machining

Vacuum sintering is exceptionally effective at producing near-net-shape parts—components that emerge from the furnace very close to their final dimensions.

This is particularly valuable for small or geometrically complex parts. By minimizing the difference between the sintered part and the final design, you drastically cut costs in two areas:

- Raw Material: Less material is used and subsequently wasted.

- Machining: Post-sintering machining is one of the most expensive and time-intensive stages of manufacturing. Reducing it saves significant money and production time.

Enhancing Process Consistency

A vacuum provides a highly controlled and repeatable environment. Factors like uniform pressure distribution and the absence of atmospheric variables lead to exceptional batch-to-batch consistency.

This high level of process control minimizes the rate of defects and rejected parts, lowering the cost of quality assurance and rework.

Understanding the Trade-offs

While powerful, vacuum sintering is not a universally superior solution. Its cost-effectiveness is dependent on the application, and you must consider its inherent trade-offs against conventional methods.

Higher Initial Capital Investment

Vacuum furnaces are significantly more complex and expensive to purchase and install than their atmospheric counterparts. This represents a substantial upfront capital expenditure that must be justified by the long-term savings.

Potentially Slower Cycle Times

The process of pulling a vacuum and carefully controlling the thermal cycle can take longer than a conventional atmospheric sintering run. This can reduce overall throughput, which may be a critical factor in high-volume manufacturing scenarios.

Specialized Operational Expertise

Operating and maintaining a vacuum furnace requires more highly skilled technicians. The need for specialized knowledge in vacuum technology, leak detection, and system maintenance can translate to higher labor costs and training requirements.

Is Vacuum Sintering the Right Choice for Your Application?

The decision to use vacuum sintering should be a strategic one based on your primary manufacturing goals and material requirements.

- If your primary focus is high-performance or reactive materials (e.g., titanium, medical-grade stainless steel): The cost is almost always justified, as it's often the only way to prevent contamination and achieve the required material properties.

- If your primary focus is producing complex, near-net-shape parts: The significant savings from reduced machining and material waste often provide a clear return on the initial investment.

- If your primary focus is mass-producing simple, low-cost parts from non-reactive materials: Conventional atmospheric sintering is likely more cost-effective due to its higher throughput and lower equipment cost.

Ultimately, vacuum sintering reduces total cost by investing in process precision upfront to eliminate expensive problems and inefficiencies downstream.

Summary Table:

| Cost Reduction Mechanism | Key Benefit |

|---|---|

| Eliminates Oxidation | No secondary processing needed, reduces contamination |

| Enhances Material Properties | Higher strength, less need for treatments |

| Reduces Waste and Machining | Near-net-shape parts save material and time |

| Improves Process Consistency | Fewer defects, lower rework costs |

Ready to cut your material processing costs with advanced vacuum sintering solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Vacuum & Atmosphere Furnaces, Muffle, Tube, and Rotary Furnaces, as well as CVD/PECVD Systems. Our deep customization capabilities ensure precise solutions for your unique experimental needs, delivering superior performance and cost efficiency. Contact us today to discuss how we can optimize your lab's processes!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high-vacuum environment necessary in copper slag impoverishment? Maximize Your Matte Separation Efficiency

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion

- What processing conditions does a vacuum furnace provide for TiCp/Fe microspheres? Sintering at 900 °C