At its core, the versatility of a rotary tube furnace stems from its unique ability to combine continuous material flow with precise thermal and atmospheric control. This design allows it to uniformly process a wide range of loose materials, from fine powders to larger pellets, making it an adaptable tool for applications spanning laboratory research, material synthesis, and industrial-scale manufacturing.

The true value of a rotary tube furnace lies not just in heating, but in its dynamic processing. By tumbling materials during heating, it ensures unparalleled uniformity and enables continuous throughput, solving key challenges in consistency and scalability that static furnaces cannot address.

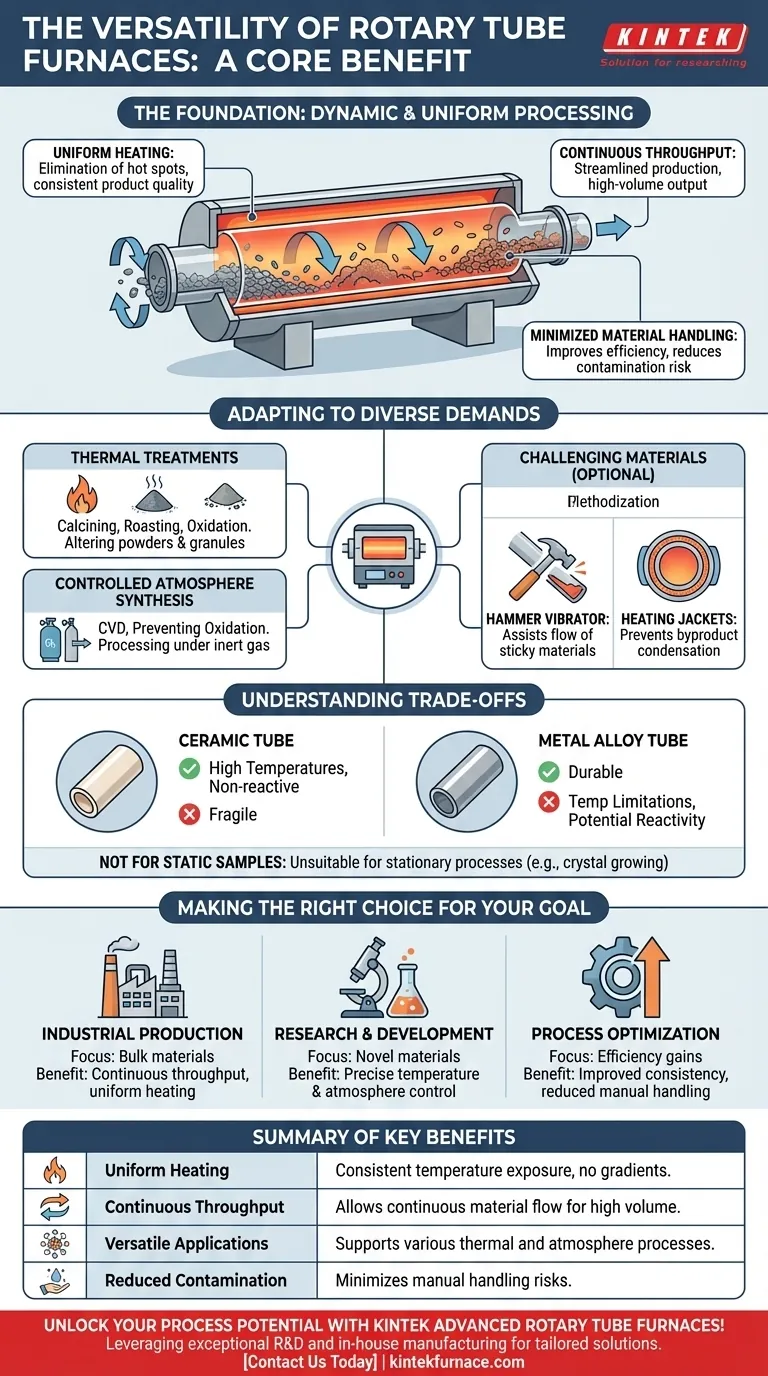

The Foundation of Versatility: Dynamic and Uniform Processing

The fundamental design of a rotary tube furnace—a rotating cylindrical chamber inside a heating element—is the source of its flexibility. This mechanism transforms a simple heating process into a dynamic and highly controlled material treatment system.

Combining Rotation with Heat Transfer

A key benefit is exceptionally uniform heating. As the tube rotates, the material inside is constantly tumbled and mixed.

This action ensures every particle is consistently exposed to the heat source, eliminating hot spots and preventing temperature gradients within the batch. The result is a highly consistent product, which is critical for quality production.

Enabling Continuous Throughput

Unlike static batch furnaces, rotary tube furnaces are designed for the continuous processing of materials. Raw material can be fed into one end of the rotating tube and the processed product can be discharged from the other.

This capability is essential for industrial applications requiring high-volume output, such as manufacturing cement clinker or iron ore pellets, as it streamlines the production line.

Minimizing Material Handling

The ability to process materials continuously significantly reduces manual handling requirements. This not only improves efficiency and lowers labor costs but also minimizes the risk of sample contamination, a crucial factor in both research and high-purity manufacturing.

Adapting to Diverse Material and Process Demands

A rotary tube furnace is not a one-size-fits-all tool but a configurable platform. Its ability to be customized with different tube materials and optional modules allows it to handle a vast array of processes.

Thermal Treatments: Calcining, Roasting, and Oxidation

These furnaces excel at high-temperature thermal treatments. Processes like calcining, which involves heating solids to drive off impurities or induce a phase transition, are common applications.

They are widely used in metallurgy for roasting ores and in materials science for oxidation processes, demonstrating their effectiveness in chemically and physically altering powders and granules.

Controlled Atmosphere Synthesis

Many models can be equipped with specialized gas handling systems, including inert gas inlets and outgassing ports. This transforms the furnace into a reactor for controlled atmosphere synthesis.

This feature is vital for processes like Chemical Vapor Deposition (CVD) or for preventing unwanted oxidation by processing materials under an inert gas like nitrogen or argon.

Processing Challenging Materials

Optional features further extend the furnace's versatility. A hammer vibrator can be added to assist the flow of high-viscosity or sticky materials that might otherwise clump together.

For processes involving organic materials, heating jackets can be fitted to the furnace ends to prevent tar and other byproducts from condensing and causing blockages.

Understanding the Trade-offs and Considerations

While highly versatile, a rotary tube furnace is not the universal solution for every thermal process. Understanding its limitations is key to making an informed decision.

Tube Material Selection is Critical

The choice between a ceramic and a metal alloy tube is a primary consideration. Ceramic tubes are necessary for extremely high temperatures or when processing materials that could react with metal. However, they can be more fragile than their metal counterparts.

Alloy tubes offer durability but have temperature limitations and may introduce contamination if they react with the process material or off-gases.

Not Ideal for Static or Solid Samples

The core strength of the furnace—its rotation—is also its main limitation. It is inherently designed for powders, granules, and other loose materials.

It is unsuitable for applications that require a sample to remain stationary and undisturbed during heating, such as growing single crystals or annealing a solid, monolithic part.

Scalability and Process Control

While these furnaces offer continuous throughput, scaling a process from a small laboratory unit to a large industrial one is not always straightforward. Factors like heat transfer dynamics, residence time, and gas flow change with size, requiring careful process re-optimization.

Making the Right Choice for Your Goal

To determine if a rotary tube furnace is right for you, consider your primary objective.

- If your primary focus is industrial production of bulk materials: The furnace's ability to provide continuous throughput and uniform heating for products like alumina or roasted ores is its most valuable asset.

- If your primary focus is research and development: Its precise control over both temperature and atmosphere makes it an ideal platform for synthesizing novel materials and studying reactions in powders.

- If your primary focus is process optimization: Its design can dramatically improve consistency and reduce manual handling compared to static batch ovens, offering significant efficiency gains.

Ultimately, the rotary tube furnace serves as a powerful bridge between laboratory-scale synthesis and industrial-scale production for any process involving the thermal treatment of loose materials.

Summary Table:

| Key Benefit | Description |

|---|---|

| Uniform Heating | Ensures consistent temperature exposure for all particles, eliminating hot spots and gradients. |

| Continuous Throughput | Allows for continuous material flow, ideal for high-volume industrial applications. |

| Versatile Applications | Supports calcining, roasting, oxidation, and controlled atmosphere synthesis for diverse materials. |

| Reduced Contamination | Minimizes manual handling, lowering the risk of sample contamination in research and manufacturing. |

Unlock the full potential of your thermal processes with KINTEK's advanced rotary tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how our versatile furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How is the Rotary Tube Tilt Furnace used in the carbon activation process? Achieve Uniform, High-Porosity Activated Carbon

- What makes rotary tube furnaces user-friendly? Achieve Superior Process Uniformity and Efficiency

- What optional features enhance the processing capabilities of rotary tube furnaces? Boost Efficiency with Advanced Customizations

- What are the advantages of a rotary tube furnace? Achieve Superior Uniformity and Efficiency in Material Processing

- How do rotary tube furnaces enhance efficiency in materials processing? Boost Throughput and Quality