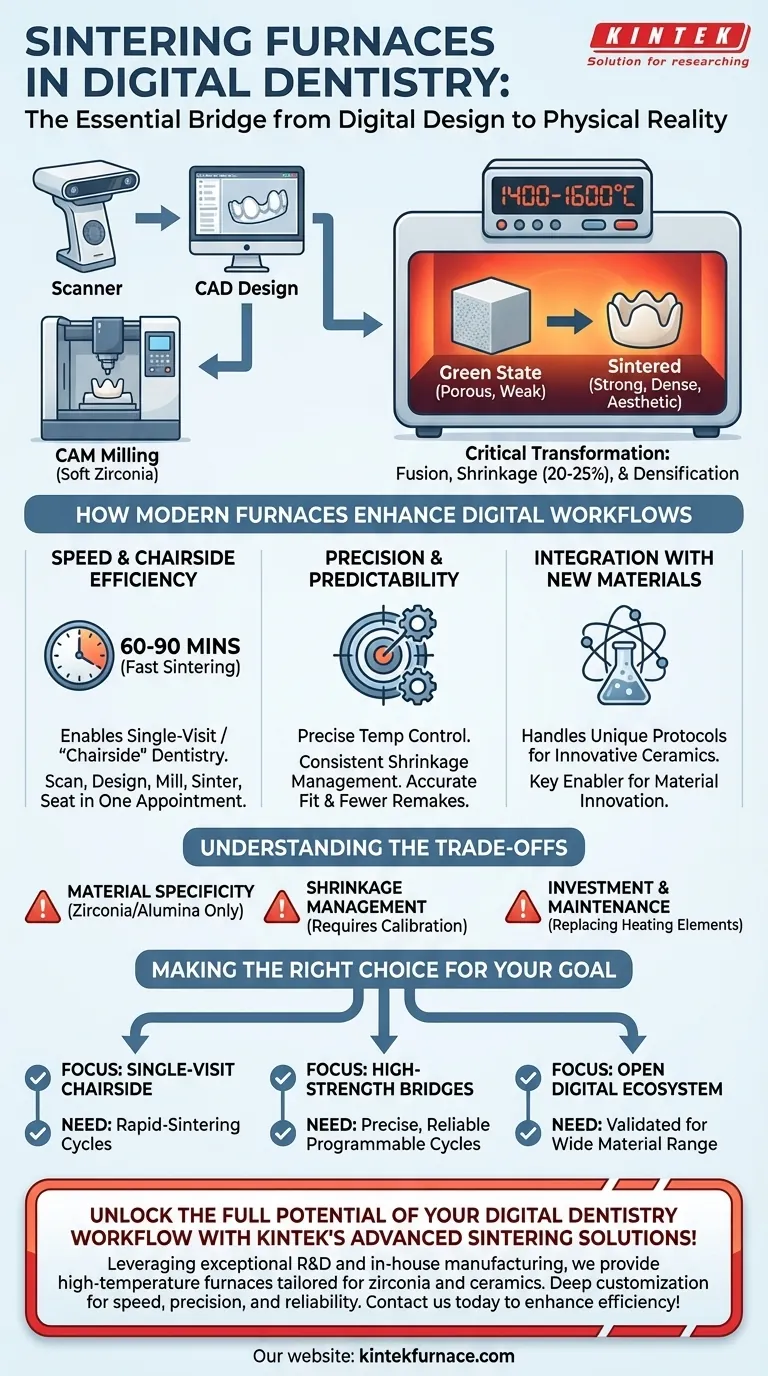

At its core, a sintering furnace acts as the final, critical link that transforms a digitally designed and milled restoration into a high-strength, clinically permanent prosthetic. It is not an alternative to digital technology but rather an essential component that unlocks the full potential of modern ceramic materials like zirconia within a digital workflow.

The sintering furnace is the indispensable bridge between the digital world of CAD/CAM design and the physical reality of a durable, aesthetic dental restoration. Without it, the most common high-strength materials used in digital dentistry would remain in a weak, unusable state.

From Digital File to Physical Crown

The journey from a digital scan to a final crown illustrates the furnace's role. A digital workflow does not replace the need for physical processing; it makes that processing more precise, predictable, and efficient.

The Role of CAD/CAM Milling

First, a dentist or lab technician uses CAD (Computer-Aided Design) software to design a restoration, such as a crown or bridge.

This digital file is then sent to a CAM (Computer-Aided Manufacturing) milling machine. The machine carves the restoration out of a block of pre-sintered, chalk-like zirconia. At this stage, the material is soft enough to be milled quickly and accurately.

Sintering: The Critical Transformation

The milled, "green state" zirconia restoration is weak and oversized. It is then placed into the sintering furnace.

The furnace executes a precise, pre-programmed heating cycle, raising the temperature to between 1,400°C and 1,600°C. This intense heat fuses the ceramic particles together, a process known as sintering.

Achieving Final Strength and Aesthetics

During sintering, the material undergoes a controlled and significant shrinkage (often 20-25%), which the initial CAD software must precisely account for.

This process transforms the porous, chalky material into a dense, non-porous solid with exceptional hardness and fracture resistance. It is only after sintering that the zirconia achieves its final strength, fit, and desired translucency for clinical use.

How Modern Furnaces Enhance Digital Workflows

Advancements in furnace technology are directly aligned with the goals of digital dentistry: speed, precision, and efficiency. They are not just simple ovens; they are sophisticated instruments.

Speed and Chairside Efficiency

The most significant advancement is the development of fast-sintering cycles. Modern furnaces can now complete a sintering or crystallization cycle in as little as 60-90 minutes, compared to many hours previously.

This speed is what enables true single-visit or "chairside" dentistry. A patient can be scanned, and the crown can be designed, milled, sintered, and seated in one appointment.

Precision and Predictability

Digital dentistry relies on predictable outcomes. Modern furnaces offer extremely precise temperature control and programmable cycles tailored to specific materials.

This ensures that the shrinkage is consistent and the final restoration matches the original digital design with microscopic accuracy, leading to better-fitting crowns and fewer remakes.

Integration with New Materials

As dental manufacturers develop new and improved ceramics, advanced sintering furnaces are designed to handle their unique firing protocols. This makes them a key enabler for material innovation within the digital ecosystem.

Understanding the Trade-offs

While essential, integrating a sintering furnace involves understanding its specific role and limitations.

Material Specificity

A sintering furnace is specifically designed for ceramics like zirconia and alumina. It is not used for processing other dental materials like composite resins or most 3D-printed polymers, which have their own separate curing or post-processing units.

The Shrinkage Factor

The success of the entire workflow hinges on perfectly managing the material's shrinkage. Any discrepancy between the software's calculation, the milling process, and the furnace's actual performance will result in a restoration that does not fit. This requires a well-calibrated system.

Investment and Maintenance

Sintering furnaces are a significant capital investment. They also require ongoing maintenance, primarily the eventual replacement of their heating elements (often molybdenum disilicide), which degrade over time with high-temperature use.

Making the Right Choice for Your Goal

Selecting and implementing this technology depends entirely on your clinical or business objectives.

- If your primary focus is single-visit chairside dentistry: A furnace with proven, rapid-sintering cycles is an absolute necessity to complete the workflow in a timely manner.

- If your primary focus is producing high-strength, multi-unit bridges and frameworks: You need a furnace with precise, reliable, and programmable cycles to ensure the accuracy and integrity of large-span restorations.

- If your primary focus is integrating with an open digital ecosystem: Prioritize a furnace that is validated to work with a wide range of zirconia materials from different manufacturers, not just a single proprietary brand.

Ultimately, the modern sintering furnace is the technology that gives digitally produced restorations their physical strength and clinical value.

Summary Table:

| Key Aspect | Role in Digital Dentistry |

|---|---|

| Function | Transforms milled zirconia into strong, durable restorations through high-temperature sintering |

| Benefits | Enables single-visit dentistry, ensures precise fit, and supports material innovation |

| Advancements | Fast-sintering cycles (60-90 minutes), precise temperature control, and integration with CAD/CAM |

| Considerations | Material-specific (e.g., zirconia), requires shrinkage management, and involves investment in maintenance |

Unlock the full potential of your digital dentistry workflow with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide dental labs and clinics with high-temperature furnaces tailored for zirconia and other ceramics. Our products, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, offer deep customization to meet your unique needs for speed, precision, and reliability. Contact us today to enhance your efficiency and deliver superior dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations