In short, rotating the furnace tube is the most effective way to heat powders and granular materials uniformly. By constantly tumbling the contents, the rotation ensures every particle receives consistent exposure to the heat source. This dynamic mixing prevents localized overheating of material touching the furnace walls and eliminates under-heated cold spots in the center of the material bed, resulting in a homogenous, high-quality final product.

The core challenge in heating bulk solids is uneven heat transfer. A rotary furnace solves this by replacing slow, static conduction with active, dynamic mixing, guaranteeing that the entire batch of material reaches the target temperature consistently and efficiently.

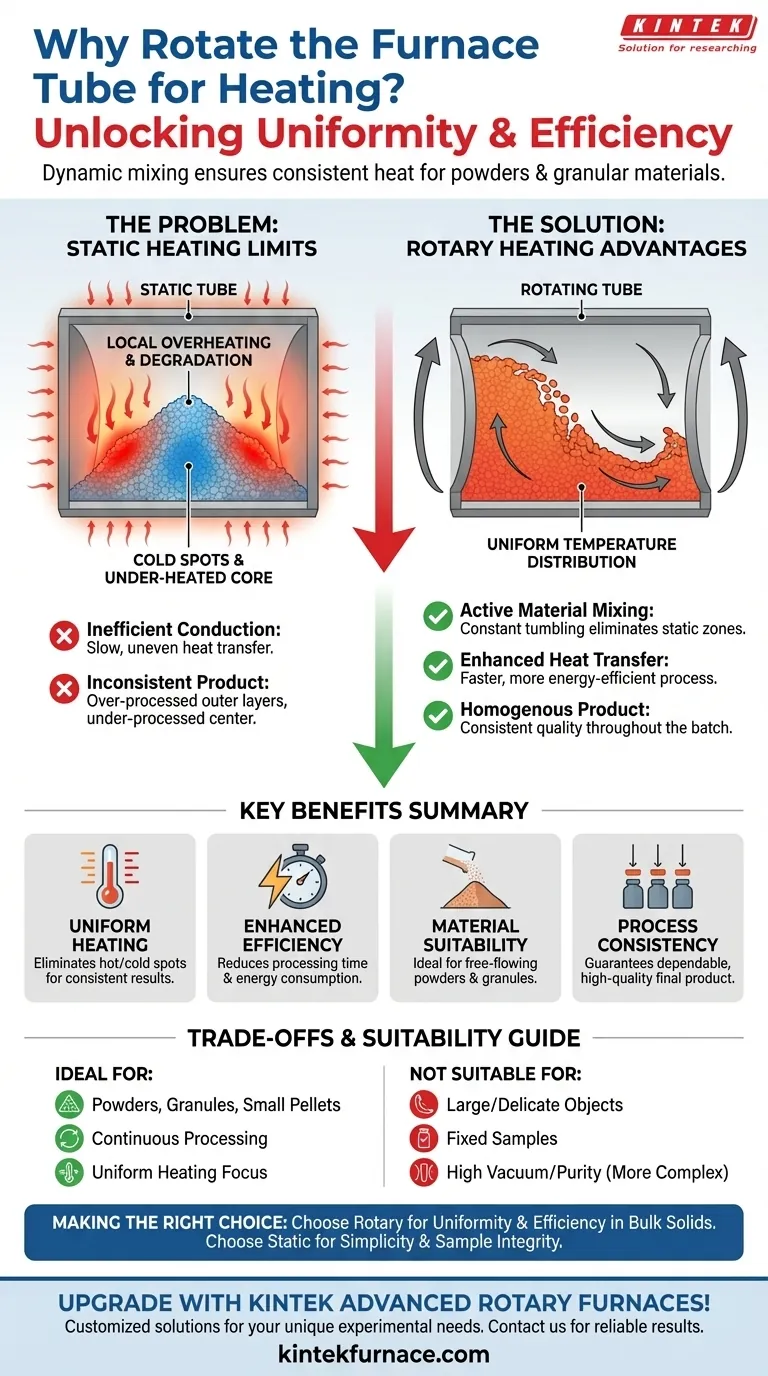

The Core Problem: The Limits of Static Heating

In a standard, non-rotating tube furnace, the material being processed sits motionless. This creates significant challenges for achieving uniform heat, especially with powders, grains, or other bulk solids.

The Inefficiency of Conduction

Heat from the furnace's heating elements is transferred to the tube wall. For a static pile of material, that heat must then travel from the outer layers to the core primarily through conduction. This is an inherently slow and inefficient process.

The particles in direct contact with the hot tube wall absorb heat quickly, while the particles in the center messaggiof the pile remain insulated and cool.

The Risk of Local Overheating

To ensure the core of the material reaches the target temperature, operators are often forced to increase the furnace's setpoint or extend the processing time.

This strategy inevitably overheats and degrades the outer layers of material that are in constant contact with the tube wall. The result is an inconsistent product where some material is over-processed and some is under-processed.

How Rotation Provides the Solution

Introducing rotation fundamentally changes the physics of the heating process, shifting from inefficient static heating to highly efficient dynamic heating.

Creating Active Material Mixing

The primary function of rotation is to continuously tumble the material. As the tube turns, it lifts material from the bottom of the pile and allows it to cascade over the top surface.

This constant turnover ensures that no single particle remains in one position for long.

Promoting Uniform Temperature Distribution

This mixing action methodically exposes all particles to the different temperature zones within the furnace. Cooler particles from the core are brought to the hot wall to absorb heat, while hotter particles from the wall are mixed back into the cooler bulk.

This process averages the temperature across the entire volume of material, achieving a highly uniform temperature distribution that is impossible in a static system.

Enhancing Heat Transfer Efficiency

By constantly presenting new, cooler material to the hot furnace wall, rotation dramatically increases the rate of heat transfer. This can significantly reduce the required processing time and lower energy consumption.

The result is a faster, more energy-efficient process and a more consistent end product.

Understanding the Trade-offs

While highly effective, a rotary tube furnace is not the universal solution for all applications. Understanding its limitations is key to making an informed decision.

Material Suitability

Rotation is ideal for free-flowing solids like powders, granules, and small pellets. It is unsuitable for processing large, single objects, delicate crystalline structures that could be damaged by tumbling, or applications where a sample's orientation must be maintained.

Mechanical Complexity

A rotary furnace is mechanically more complex than its static counterpart. It requires a drive motor, a rotation system, and, crucially, specialized seals at the ends of the tube. These components require more maintenance and can be potential points of failure.

Atmosphere and Vacuum Integrity

While possible, maintaining a high-purity gas atmosphere or a deep vacuum can be more challenging in a rotary furnace. The rotating seals must be perfectly engineered and maintained to prevent leaks, adding a layer of operational complexity compared to a simpler, sealed static tube.

Making the Right Choice for Your Process

The decision between a static and a rotary furnace should be driven by your material's form and your final processing goal.

- If your primary focus is on heating powders, granules, or bulk solids uniformly: A rotary tube furnace is the superior choice to guarantee consistency and prevent material degradation.

- If your primary focus is on continuous processing or calcination: The tumbling action and ability to tilt a rotary furnace make it ideal for moving material through a heat zone at a controlled rate.

- If your primary focus is on heating a single solid part, a fixed sample, or a delicate structure: A static tube furnace is the correct choice to maintain sample integrity and avoid mechanical damage.

- If your primary focus is on maximum simplicity and minimal maintenance: A static tube furnace offers a simpler design with fewer moving parts and is generally easier to operate.

By understanding that rotation is a tool to solve the specific problem of non-uniform heating in bulk solids, you can confidently select the technology that will deliver the most efficient and reliable results for your application.

Summary Table:

| Benefit | Description |

|---|---|

| Uniform Heating | Ensures all particles receive consistent heat exposure through tumbling, eliminating cold spots and overheating. |

| Enhanced Efficiency | Reduces processing time and energy consumption by improving heat transfer rates. |

| Material Suitability | Ideal for free-flowing solids like powders and granules, but not for large or delicate objects. |

| Process Consistency | Guarantees homogenous final product quality by preventing localized degradation. |

Upgrade your laboratory with KINTEK's advanced rotary furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for uniform heating and efficiency. Contact us today to discuss how our tailored solutions can enhance your process and deliver reliable results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs