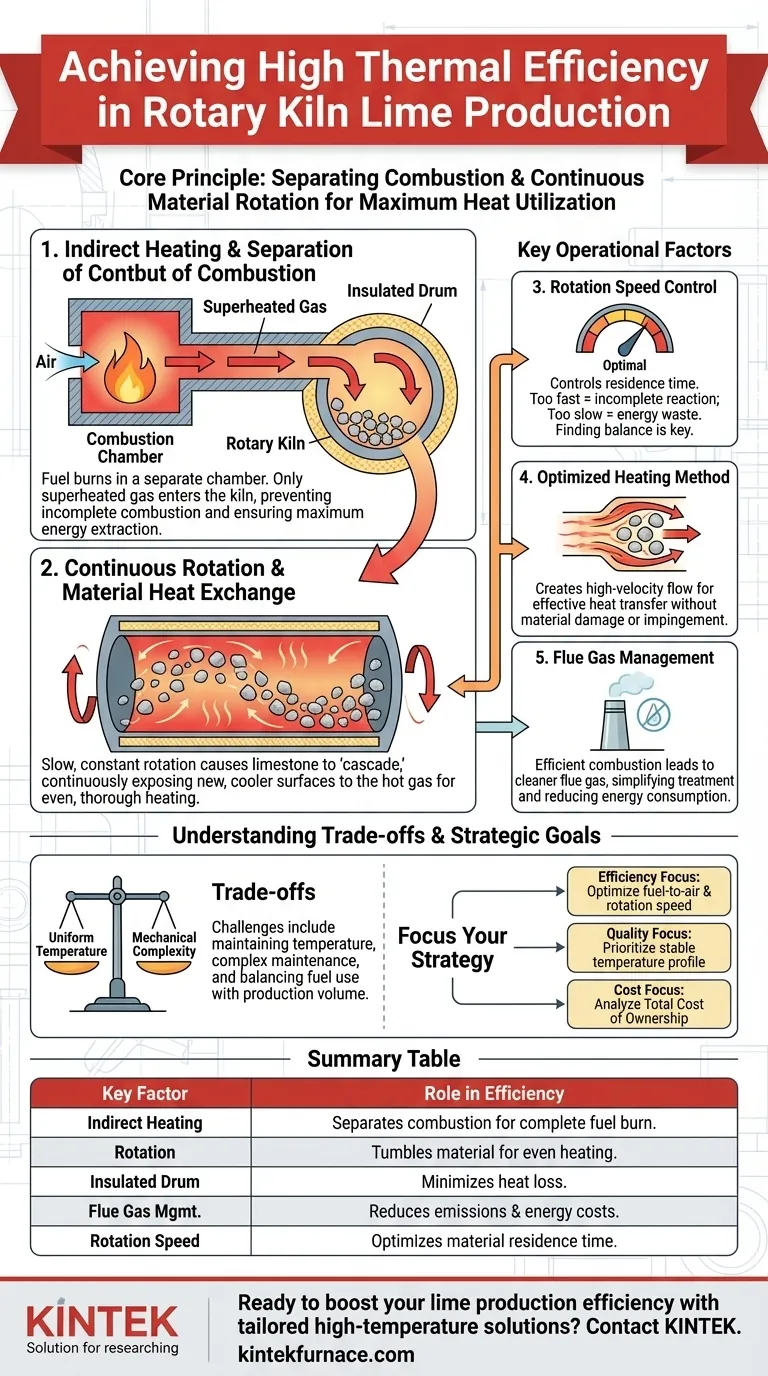

At its core, a rotary kiln for lime production achieves high thermal efficiency through its specialized design that separates fuel combustion from the limestone itself. This indirect heating method, combined with the kiln's continuous rotation, ensures that hot gases transfer their energy to the material with minimal waste, maximizing the heat utilization from every unit of fuel.

The fundamental principle behind the rotary kiln's efficiency is not just heating, but controlled and comprehensive heat exchange. By separating the intense combustion process and continuously tumbling the material, the system ensures the maximum amount of thermal energy is absorbed by the limestone before it can escape as waste.

The Core Principle: Indirect Heating and Heat Exchange

The design of a rotary lime kiln is engineered to solve one primary problem: how to heat a large volume of material to a precise temperature as efficiently as possible. The solution lies in how it manages heat transfer.

Separating Combustion from Material

In many efficient rotary kiln designs, the fuel is burned in a dedicated combustion chamber. The resulting superheated gas, not the direct flame, is then channeled into the kiln to heat the limestone.

This separation prevents incomplete combustion that can occur when a flame is smothered by material. It allows for a cleaner, more complete burn, extracting the maximum possible energy from the fuel source.

Maximizing Heat Transfer Through Rotation

The kiln's slow, constant rotation is critical. It causes the limestone to tumble, or "cascade," inside the drum.

This action continuously exposes new, cooler surfaces of the limestone to the hot gases. This prevents the formation of an insulating outer layer and ensures the material is heated evenly and thoroughly, driving the chemical reaction (calcination) to completion.

Reducing Wasted Energy

By containing the process within a long, insulated rotating drum, the system minimizes heat loss to the surrounding environment. The hot flue gases travel the length of the kiln, transferring their energy to the material along the way. This design ensures that by the time the gases exit the system, they have given up a significant portion of their thermal energy.

Key Operational Factors for Efficiency

Beyond the core design, several operational parameters must be carefully managed to maintain peak efficiency.

The Critical Role of Rotation Speed

The kiln's rotation speed directly controls the residence time of the material—how long the limestone spends inside.

If the speed is too high, the limestone passes through too quickly and doesn't have enough time to absorb sufficient heat, resulting in an incomplete reaction. If it is too slow, it can lead to material buildup and inefficient heat spots, wasting energy. Finding the optimal balance is key to both efficiency and product quality.

Optimizing the Heating Method

Rotary kilns can be heated directly (a burner inside the kiln) or indirectly (heat from an external chamber). While direct firing is common, the most efficient systems focus on controlling the interaction between the hot gas and the material.

The goal is to create a high-velocity flow of hot gas that transfers heat effectively without directly impinging on and potentially damaging the material or being wasted.

Benefits of Flue Gas Management

Efficient combustion results in cleaner flue gas. This not only reduces the environmental impact but also lowers costs.

Because the emissions are relatively low and predictable, the required equipment for gas treatment is simpler and less energy-intensive, contributing to the kiln's overall operational and energy efficiency.

Understanding the Trade-offs

While highly efficient, the rotary kiln design is not without its challenges and compromises.

The Challenge of Uniform Temperature

Maintaining a perfectly consistent temperature profile along the entire length of a massive industrial kiln is a significant engineering challenge. Any "cold spots" can result in under-burnt lime, reducing product quality and wasting the energy that was used.

Mechanical Complexity and Maintenance

The rotating drum, seals, drive system, and internal refractory lining are complex mechanical systems that operate under extreme stress and heat. They require regular, intensive maintenance, and any downtime represents a significant loss of production and efficiency.

Balancing Efficiency vs. Throughput

The operational settings that yield the absolute highest thermal efficiency might not align with the plant's need for maximum production output (throughput). Operators must constantly make decisions that balance fuel consumption per ton of lime against the demand for total tons produced per day.

Making the Right Choice for Your Goal

Understanding these principles allows you to focus your operational strategy on what matters most to your specific objectives.

- If your primary focus is maximizing thermal efficiency: Concentrate on optimizing the fuel-to-air ratio for complete combustion and fine-tuning the rotation speed to maximize heat absorption.

- If your primary focus is ensuring product quality: Prioritize maintaining a stable and uniform temperature profile throughout the kiln, even if it requires slightly more fuel.

- If your primary focus is lowering overall costs: Analyze the total cost of ownership, which includes fuel savings, reduced environmental compliance expenses, and predictive maintenance schedules to minimize downtime.

By mastering the interplay between its design and operational parameters, you can fully leverage the rotary kiln's potential for efficient, high-quality lime production.

Summary Table:

| Key Factor | Role in Efficiency |

|---|---|

| Indirect Heating | Separates combustion from material for cleaner, complete fuel burn and better heat transfer. |

| Rotation | Tumbles limestone to expose new surfaces, ensuring even heating and preventing insulation buildup. |

| Insulated Drum | Minimizes heat loss to the environment, retaining thermal energy within the system. |

| Flue Gas Management | Reduces emissions and simplifies gas treatment, cutting energy and compliance costs. |

| Rotation Speed Control | Optimizes material residence time for complete calcination and minimal energy waste. |

Ready to boost your lime production efficiency with tailored high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnace systems like Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs, helping you achieve superior thermal efficiency and energy conservation. Contact us today to discuss how we can optimize your process!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules