At its core, the process of using a dental sintering furnace is a highly controlled thermal treatment that transforms a fragile, pre-shaped dental restoration into its final, high-strength state. This involves placing the restoration (often made of zirconia) into the furnace, where it is subjected to a precise, pre-programmed cycle of heating and cooling in a controlled atmosphere. This fuses the material's particles, causing it to densify and achieve its desired structural integrity, color, and translucency.

Sintering is not merely a heating process; it is a meticulous transformation. Its success hinges on the precise control of temperature, time, and atmosphere to convert a chalk-like pre-milled part into a durable, biocompatible, and esthetic final dental prosthesis.

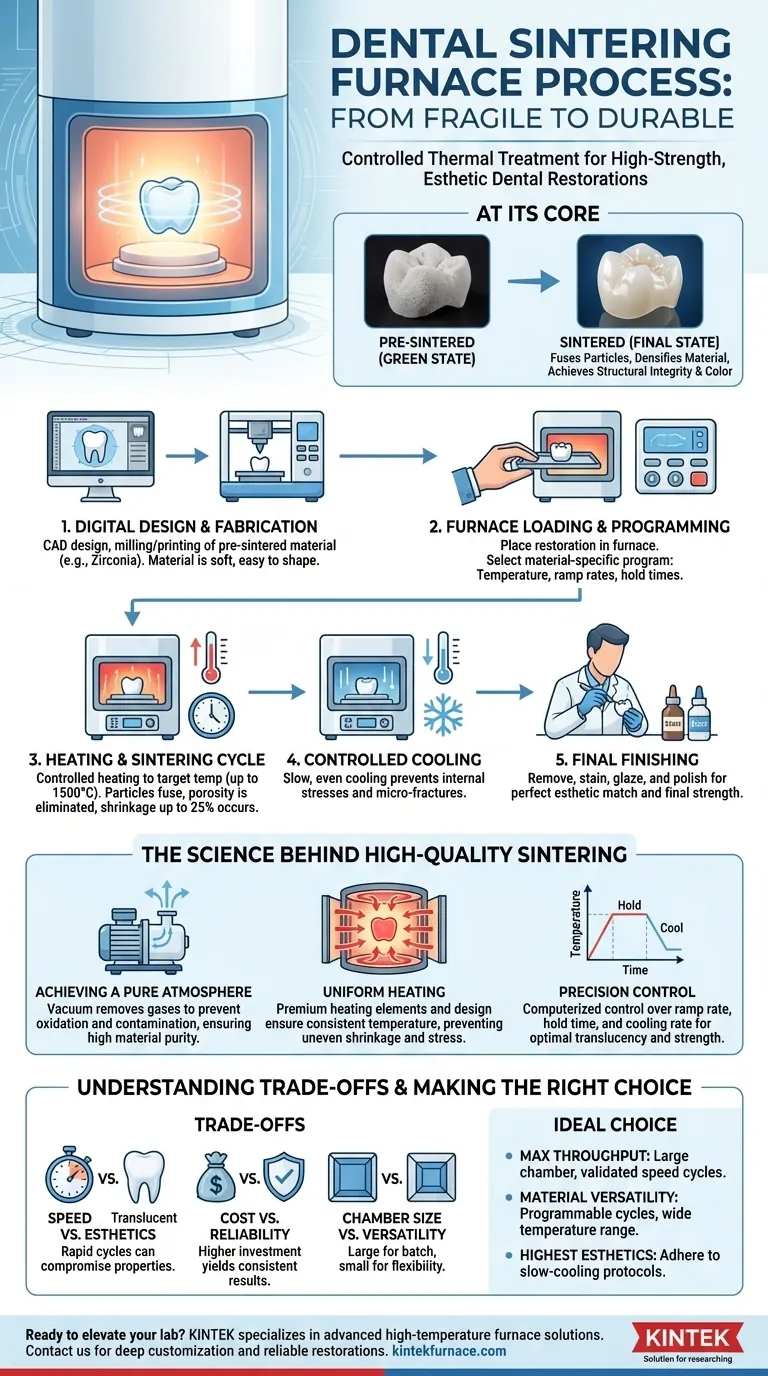

The Step-by-Step Sintering Workflow

The sintering furnace is a critical component in a larger digital dentistry workflow. The quality of the final product depends on executing each step with precision.

Step 1: Digital Design and Fabrication

Before the furnace is even turned on, the restoration is designed using CAD (Computer-Aided Design) software. This digital file is then sent to a milling machine or 3D printer, which carves or builds the restoration from a block of pre-sintered material, most commonly zirconia.

In this pre-sintered state, the material is soft and chalk-like, making it easy to mill accurately.

Step 2: Furnace Loading and Programming

The milled "green state" restoration is carefully placed into the sintering furnace, typically on a specialized tray or crucible.

The technician then selects the correct program on the computerized furnace control panel. This program is specific to the material being used, as different types of zirconia or other ceramics require unique heating temperatures, ramp rates, and hold times.

Step 3: The Heating and Sintering Cycle

The furnace initiates the cycle, slowly raising the temperature at a controlled "ramp rate." This gradual heating prevents thermal shock, which could crack the restoration.

Once it reaches the target sintering temperature (which can be upwards of 1500°C for zirconia), the furnace holds this temperature for a specific period. During this phase, the particles of the material fuse together, eliminating porosity and causing the restoration to shrink by up to 25% and harden significantly.

Step 4: Controlled Cooling

The cooling phase is just as critical as the heating phase. The furnace must lower the temperature slowly and evenly to prevent internal stresses and micro-fractures from developing in the newly hardened ceramic.

Step 5: Final Finishing

After the cycle is complete and the restoration has fully cooled, it is removed from the furnace. It has now reached its final size, strength, and shade. The final step involves minor adjustments, staining, glazing, and polishing to match the patient's natural teeth perfectly.

The Science Behind High-Quality Sintering

Understanding the technology within the furnace reveals why this process is so fundamental to producing reliable restorations.

Achieving a Pure Atmosphere

Many advanced furnaces create a vacuum inside the chamber before the heating cycle begins. This removes atmospheric gases like oxygen that can cause oxidation and contaminate the material, especially when sintering metals or sensitive alloys. This ensures high material purity and enhances its final mechanical properties.

Uniform Heating for Structural Integrity

The core function of a quality furnace is to deliver perfectly uniform heat. Cold spots or hot spots in the chamber cause uneven shrinkage, creating internal stress that can lead to catastrophic failure of the restoration later on.

High-quality heating elements, such as those made from silicon carbide, and intelligent furnace design are critical for ensuring every part of the restoration is heated to the exact same temperature at the same time.

The Importance of Precision Control

Modern furnaces are computerized for a reason. They precisely manage the ramp rate (how fast the temperature rises), the hold time at peak temperature, and the cooling rate. This "recipe" is vital for achieving the material's specified translucency, strength, and color.

Understanding the Trade-offs

While modern furnaces are highly automated, the operator must still make critical decisions that balance efficiency with quality.

Speed vs. Final Esthetics

Many furnaces offer "speed" or "fast" sintering cycles that can dramatically reduce processing time. While this improves a lab's productivity, these rapid cycles can sometimes result in lower translucency or slightly compromised strength compared to the manufacturer's standard, slower cycle.

Investment Cost vs. Reliability

A high-end furnace with premium heating elements, a vacuum pump, and advanced controls represents a significant capital investment. However, this cost is often justified by greater reliability, consistent results, and fewer failed restorations, which directly impacts a dental lab's profitability and reputation.

Chamber Size vs. Versatility

A large chamber allows a lab to sinter many restorations at once, maximizing throughput. However, a smaller furnace may heat up faster and be more energy-efficient for single-unit cases, offering more flexibility for urgent jobs.

Making the Right Choice for Your Goal

The ideal sintering process is one that aligns with the specific goals of the dental lab and the requirements of the case.

- If your primary focus is maximum throughput: Prioritize a furnace with a large, reliable chamber and validated speed cycles to process batch cases efficiently.

- If your primary focus is material versatility: Choose a furnace with fully programmable cycles and a wide temperature range to handle different zirconia generations, e.max (lithium disilicate), and other ceramic materials.

- If your primary focus is the highest possible esthetics: Strictly adhere to the material manufacturer's recommended slow-cooling protocols, as this is proven to yield the best optical properties and strength.

Mastering the sintering process empowers you to consistently translate a digital design into a strong, beautiful, and long-lasting dental restoration.

Summary Table:

| Step | Description | Key Factors |

|---|---|---|

| 1. Digital Design & Fabrication | CAD design and milling of pre-sintered material (e.g., zirconia) | Accuracy in milling, material type |

| 2. Furnace Loading & Programming | Place restoration in furnace; select material-specific program | Program selection, ramp rate, temperature |

| 3. Heating & Sintering Cycle | Controlled heating to fuse particles, densify material | Temperature (up to 1500°C), hold time, uniform heating |

| 4. Controlled Cooling | Gradual cooling to prevent stress and fractures | Cooling rate, atmosphere control |

| 5. Final Finishing | Adjust, stain, glaze, and polish restoration | Esthetic matching, strength verification |

Ready to elevate your dental lab's sintering process? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs, ensuring reliable, high-strength dental restorations. Contact us today to discuss how our tailored furnace solutions can enhance your productivity and quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time