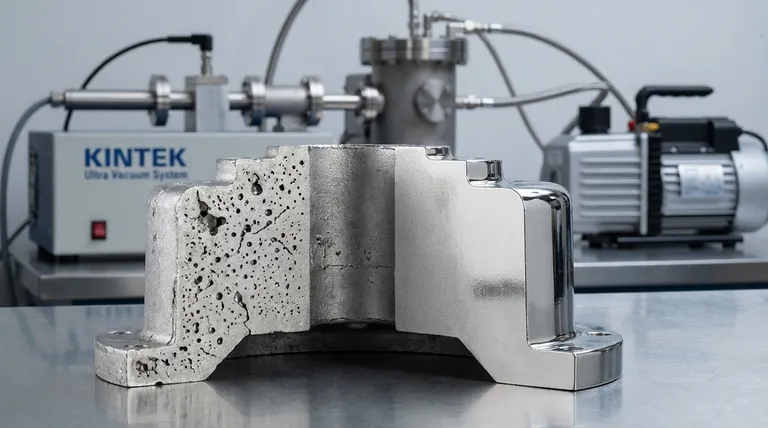

The integration of a vacuum system enhances die casting quality by extracting air from the mold cavity immediately before the molten metal is injected. This extraction minimizes the entrapment of gas, directly resolving the issue of porosity and resulting in a component that is denser, structurally stronger, and compatible with advanced finishing processes.

By eliminating air pockets that lead to gas holes, vacuum systems transform die casting from a simple shaping process into a method capable of producing high-density, structural-grade components suitable for demanding surface finishes.

The Mechanism of Defect Reduction

To understand the value of a vacuum system, you must first understand the primary enemy of die casting quality: porosity.

Evacuating the Mold Cavity

In standard die casting, air naturally fills the mold. When metal is injected at high speeds, this air can become trapped.

A vacuum system intervenes by sucking this air out of the cavity just prior to injection. This creates a void that the molten metal can fill completely without competing with atmospheric pressure.

Minimizing Gas Holes

The immediate result of air extraction is a significant reduction in gas holes.

These are microscopic or macroscopic bubbles that form within the metal as it solidifies. By removing the air beforehand, the vacuum system ensures the metal matrix remains solid and continuous.

Impact on Physical Properties

The removal of gas does more than just clean up the interior of the part; it fundamentally changes the physical characteristics of the metal.

Achieving Higher Internal Density

With the absence of gas pockets, the molten metal packs together more tightly.

This results in higher internal density. The part is no longer a honeycomb of microscopic voids but a solid, cohesive unit.

Improving Mechanical Integrity

Density correlates directly with strength. A part with fewer internal defects possesses superior mechanical integrity.

These components are better equipped to handle stress and load without failure, making them suitable for critical structural applications where standard castings might fail.

Unlocking Surface Finish Potential

For many manufacturers, the most critical advantage of vacuum die casting is not just strength, but the ability to apply high-end finishes.

Enabling Electroplating

Secondary processes like electroplating are notoriously sensitive to surface defects.

If a part has internal porosity, chemicals can become trapped or gas can expand, causing surface blisters. Vacuum casting provides the dense, defect-free surface required for a flawless plated finish.

Facilitating High-Quality Painting

Similar to plating, high-quality painting often involves heat curing.

trapped gas in a porous part can expand under heat, ruining the paint job. The vacuum process ensures the surface is stable and suitable for premium cosmetic applications.

Understanding the Contextual Trade-offs

While vacuum systems offer clear quality benefits, it is important to view them as a specific tool for specific requirements.

Process Complexity

Integrating a vacuum system adds a layer of sophistication to the casting cycle.

It is a specialized step intended for parts where structural integrity or surface finish is non-negotiable. It transforms the process from a general forming method into a precision engineering solution.

Making the Right Choice for Your Goal

Deciding to utilize vacuum die casting depends entirely on the end-use requirements of your component.

- If your primary focus is mechanical durability: The vacuum system is essential for creating high-density parts that maintain structural integrity under stress.

- If your primary focus is cosmetic excellence: The system is required to produce the defect-free substrates necessary for successful electroplating or high-quality painting.

Vacuum integration is the definitive solution for bridging the gap between standard die casting and high-performance, precision manufacturing.

Summary Table:

| Feature | Standard Die Casting | Vacuum-Integrated Die Casting |

|---|---|---|

| Gas Porosity | High risk of air entrapment | Minimized via cavity evacuation |

| Internal Density | Lower (honeycomb potential) | Higher (solid cohesive matrix) |

| Mechanical Strength | Standard structural integrity | Superior load-bearing integrity |

| Surface Finishing | Limited by gas blisters | Ideal for electroplating & painting |

| Best For | General shaping | Precision & high-performance parts |

Elevate Your Manufacturing Precision with KINTEK

Is porosity compromising your component quality? KINTEK provides the advanced thermal and vacuum solutions needed to achieve structural-grade excellence. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique precision die casting and heat treatment needs.

Take the next step in precision engineering. Contact our specialists today to discuss how our customizable vacuum systems can enhance your material integrity and surface finish potential.

References

- S. B. Pulate, V.R. Lawande. A Comprehensive Study on Pressure Die Casting: Process Mechanisms, Material Science, Challenges, and Future Trends. DOI: 10.32628/ijsrset251256

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is a high vacuum environment necessary during the SPS of CoCrFeMnNi alloy powders? Ensure Purity and Density

- How does a vacuum furnace ensure high-quality output? Achieve Superior Purity and Performance for Your Materials

- What are the different classifications of vacuum furnaces based on pressure range? Explore High-Vacuum vs. UHV for Your Lab

- What ceramic materials can be processed in vacuum heat treatment furnaces? Unlock High-Purity Processing for Advanced Ceramics

- What type of pumping systems are used in high vacuum furnaces? Essential Guide for Clean and Efficient Processing

- How does vacuum sintering compare to traditional smelting methods? Discover Key Differences for Your Manufacturing Needs

- What is the standard of vacuum heat treatment? Mastering Purity, Precision, and Performance

- How does optimizing the graphite base material improve the quality of cemented carbide sintering? Master Thermal Uniformity