At its core, an IGBT induction melting furnace improves efficiency by using advanced solid-state electronics to precisely control the electrical frequency and power delivered to the melt. This technology, built around the Insulated Gate Bipolar Transistor (IGBT), allows the furnace to constantly adapt to the changing electrical properties of the non-magnetic charge, ensuring maximum energy transfer throughout the entire smelting process.

The fundamental advantage of an IGBT furnace is its ability to decouple the operating frequency from the load. This allows it to maintain optimal power delivery from a cold start to a fully molten state, a critical factor for efficiently melting non-magnetic materials like copper and aluminum.

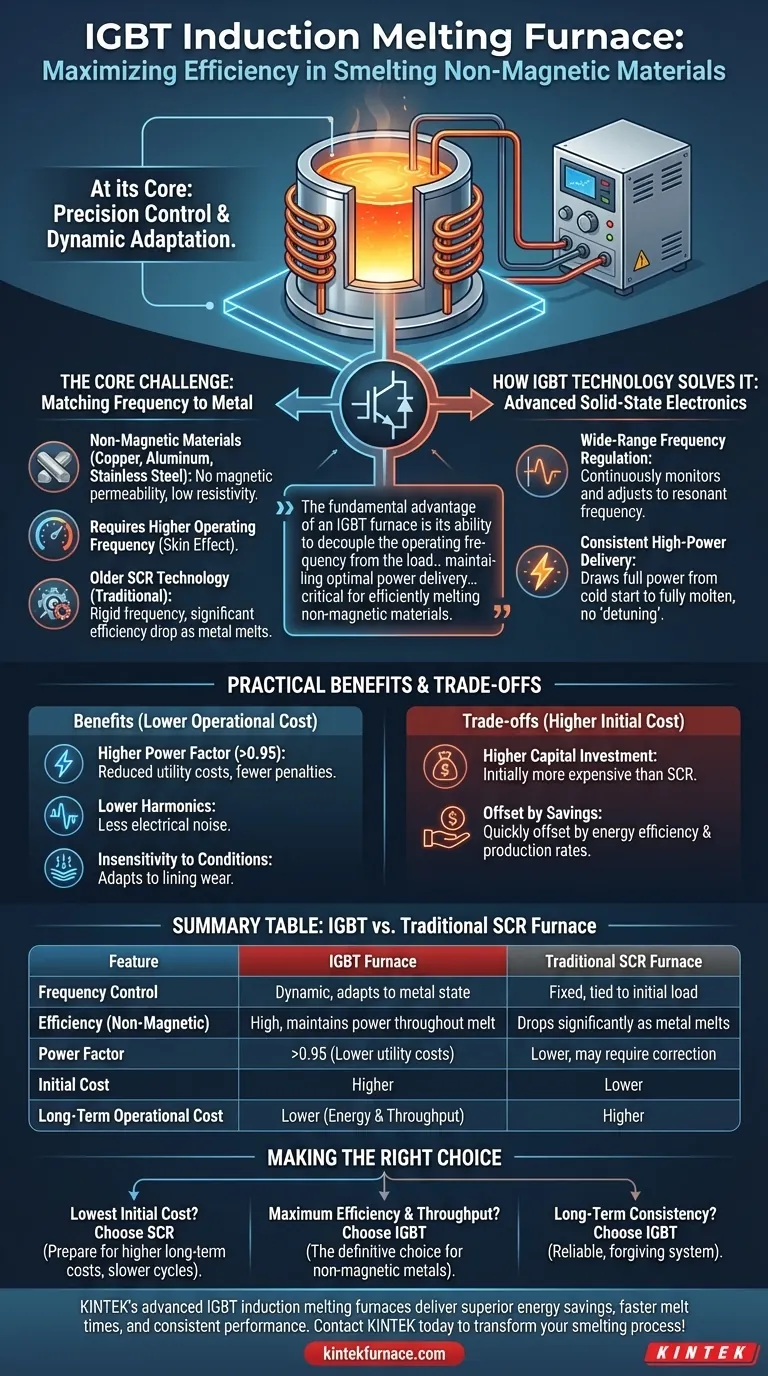

The Core Challenge: Matching Frequency to the Metal

To understand the IGBT's impact, we must first understand the physics of induction and the specific challenges posed by non-magnetic materials.

The Principle of Induction Heating

Induction heating works by creating a powerful, alternating magnetic field within a coil. When a conductive material like metal is placed inside, this field induces powerful electrical currents within the metal itself, known as eddy currents. The metal's natural resistance to these currents generates immense heat, causing it to melt.

The Problem with Non-Magnetic Materials

The efficiency of this process depends heavily on the electrical frequency and the properties of the metal. Non-magnetic materials like copper, aluminum, and stainless steel have no magnetic permeability and typically low electrical resistivity.

This means they require a higher operating frequency to generate heat efficiently. The heating is concentrated near the surface—a phenomenon called the skin effect—and a higher frequency creates a thinner, more intense heating layer, improving energy transfer.

The Limitation of Older Technology

Older furnaces often use SCR (Silicon Controlled Rectifier) technology. In these systems, the operating frequency is rigidly tied to the physical characteristics of the furnace coil and the metal charge (the "load").

As the metal heats up and melts, its electrical properties change dramatically. This causes the ideal resonant frequency to shift. An SCR furnace cannot effectively "chase" this moving target, causing a significant drop in power and efficiency mid-melt.

How IGBT Technology Solves the Problem

The IGBT is a high-power, high-speed electronic switch that fundamentally changes the furnace's power supply architecture.

The Power of Wide-Range Frequency Regulation

An IGBT-based power supply (known as a series inverter) can operate over a very wide frequency range. A sophisticated control system continuously monitors the furnace's electrical state.

This system uses a feedback loop to instantly adjust the output frequency to match the exact resonant frequency of the coil and charge at any given moment. This is true frequency regulation.

Maintaining Maximum Power from Start to Finish

Because the furnace can always operate at its most efficient frequency, it can draw full power from the power supply throughout the entire cycle. It does not "detune" as the metal melts.

This results in a consistent, high-power delivery that significantly shortens melting times and reduces the total energy (kWh) consumed per ton of metal produced. This is the essence of its superior power regulation.

Understanding the Practical Benefits and Trade-offs

While the technology is superior, it's important to weigh its benefits against its costs.

Higher Power Factor and Lower Harmonics

Modern IGBT power supplies achieve a very high power factor (typically above 0.95) without needing large, expensive capacitor banks. This reduces electricity costs by minimizing penalties from the utility provider. They also produce far less electrical noise, or "harmonics," on the power grid.

Insensitivity to Operating Conditions

The reference correctly notes that efficiency is less affected by the charge or lining thickness. As the refractory lining wears down over time, its properties change, which would detune an older SCR furnace.

The IGBT system simply adapts, finding the new optimal frequency and continuing to run at peak efficiency. This makes its performance more consistent and reliable over the long term.

The Cost-Benefit Analysis

The primary trade-off is the initial capital cost. IGBT furnaces are generally more expensive to purchase than their SCR counterparts.

However, this higher upfront cost is often quickly offset by significant operational savings through lower energy consumption, faster production rates (higher throughput), and reduced utility penalties.

Making the Right Choice for Your Goal

Your decision should be based on a clear understanding of your operational priorities and financial model.

- If your primary focus is the lowest possible initial capital cost: An SCR-based furnace may seem attractive, but you must budget for higher long-term energy consumption and potentially slower melt cycles.

- If your primary focus is maximum energy efficiency and throughput: The IGBT furnace is the definitive choice, especially when melting non-magnetic metals where its frequency control provides a clear advantage.

- If your primary focus is long-term operational consistency: The IGBT's ability to adapt to changing conditions like lining wear makes it a more reliable and forgiving system, ensuring predictable performance.

Ultimately, investing in IGBT technology is a strategic decision to prioritize long-term operational efficiency and productivity over short-term capital savings.

Summary Table:

| Feature | IGBT Furnace | Traditional SCR Furnace |

|---|---|---|

| Frequency Control | Dynamic, adapts to metal state | Fixed, tied to initial load |

| Efficiency (Non-Magnetic) | High, maintains power throughout melt | Drops significantly as metal melts |

| Power Factor | >0.95 (Lower utility costs) | Lower, may require correction |

| Initial Cost | Higher | Lower |

| Long-Term Operational Cost | Lower (Energy & Throughput) | Higher |

Ready to maximize the efficiency of your non-magnetic metal smelting operations?

KINTEK's advanced IGBT induction melting furnaces are engineered to deliver superior energy savings, faster melt times, and consistent performance. Our solutions are ideal for foundries and metal producers working with copper, aluminum, and stainless steel.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and production facilities with advanced thermal processing solutions. Our product line, including induction melting furnaces, is complemented by our strong deep customization capability to precisely meet your unique operational requirements.

Contact KINTEK today to discuss how our IGBT technology can transform your smelting process and boost your bottom line.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity