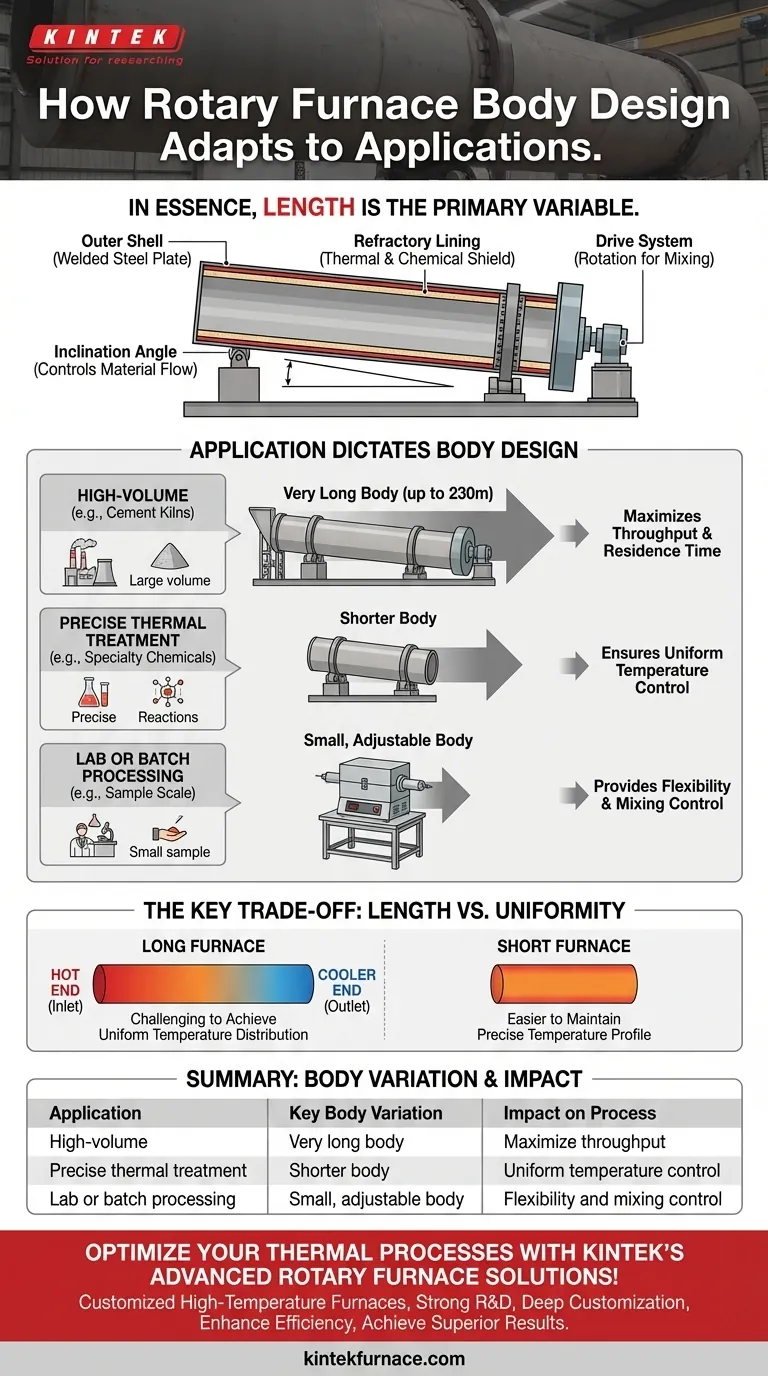

In essence, the primary way the body of a rotary furnace varies with application is its length. While the fundamental construction remains a cylindrical shell of welded steel plate, its length is scaled dramatically—from small laboratory tubes to massive kilns up to 230 meters long—to match the required material throughput and processing time for a specific industrial task.

The design of a rotary furnace body is a direct reflection of the physical and chemical demands of the process it must perform. Its length and inclination are not arbitrary; they are precisely engineered variables that control material residence time and heat exposure, representing a fundamental trade-off between production scale and process uniformity.

Deconstructing the Rotary Furnace

To understand how the furnace body adapts, we must first recognize its role within the larger system. It is the structural framework that contains and enables the entire thermal process.

The Outer Shell: The Structural Backbone

The furnace body itself is a cylindrical tube, or barrel, fabricated from welded steel plate. This steel shell provides the mechanical strength to span long distances, withstand rotation, and support the immense weight of its internal components and the material being processed.

The Inner Lining: The Thermal and Chemical Shield

Inside the steel body is a refractory lining. This layer, made of heat-resistant bricks, cement, or castable materials, serves two critical functions: it insulates the steel shell from extreme internal temperatures and protects it from chemical corrosion by the process materials. The body contains the lining, but the lining dictates the furnace's thermal and chemical limits.

The Drive System: Enabling the Process

The entire furnace body is rotated by a drive gear or a system of driven rollers. This rotation is fundamental, as it tumbles the material, ensuring it is mixed and evenly exposed to the heat source. The speed of this rotation is often variable, providing another layer of process control.

How Application Dictates Body Design

The specific requirements of an application—such as drying, calcination, or waste incineration—directly influence the physical dimensions and orientation of the furnace body.

Length and Throughput

The length of the furnace is dictated by scale and required residence time. A large-scale, continuous process like cement manufacturing requires an extremely long furnace to process a high volume of material. The longer the furnace, the more time the material spends inside, allowing for slower, more thorough reactions or drying.

Inclination Angle

Rotary furnaces are almost always mounted at a slight angle. This inclination, combined with the rotation, causes material fed into the higher end to travel gradually toward the discharge end. Adjusting this angle is a key design choice that controls how fast the material moves, directly influencing its residence time in the heat zone.

Understanding the Key Trade-off: Length vs. Uniformity

The decision to use a long furnace body is not without consequences. The most significant challenge is maintaining process control over a vast area.

The Challenge of Long Furnaces

While a furnace can be up to 230 meters long, achieving a uniform temperature distribution along its entire length is exceptionally difficult. Heat is typically introduced at one end, creating a natural temperature gradient from the hot end to the cooler end.

Why Uniformity Matters

For some bulk processes like drying or simple heating, a temperature gradient is acceptable or even desirable. However, for sensitive chemical reactions that require a precise temperature profile, the non-uniformity of a very long furnace can lead to inconsistent product quality.

Matching the Furnace Body to Your Process Goal

Choosing the right design requires balancing the need for throughput against the need for process control.

- If your primary focus is high-volume, continuous processing (e.g., cement kilns): You will require a very long, slightly inclined furnace body to maximize residence time and throughput.

- If your primary focus is precise thermal treatment (e.g., specialty chemicals, pyrolysis): A shorter furnace body is superior, as it allows for much tighter and more uniform temperature control throughout the chamber.

- If your primary focus is material mixing and heat exposure in a lab or batch setting: A smaller rotary tube furnace, which may have a more pronounced inclination or even operate horizontally, provides flexibility and control for sample-scale work.

Ultimately, the furnace body is engineered as a direct solution to the specific time, temperature, and volume requirements of your target application.

Summary Table:

| Application | Key Body Variation | Impact on Process |

|---|---|---|

| High-volume (e.g., cement kilns) | Very long body (up to 230m) | Maximizes throughput and residence time |

| Precise thermal treatment (e.g., specialty chemicals) | Shorter body | Ensures uniform temperature control |

| Lab or batch processing | Small, adjustable body | Provides flexibility and mixing control |

Optimize your thermal processes with KINTEK's advanced rotary furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing