The key is in the gradient. Sintered dental zirconia balances strength and aesthetics not by compromising, but by engineering a multi-layered structure that mimics a natural tooth. It achieves high translucency at the incisal edge for a natural look while maintaining strength and opacity at the cervical (neck) area for durability and color shading.

The genius of modern zirconia is that it is not a uniform material. It is intentionally designed with a gradient of properties, allowing it to be both aesthetically pleasing where visible and robustly strong where functional stress is highest.

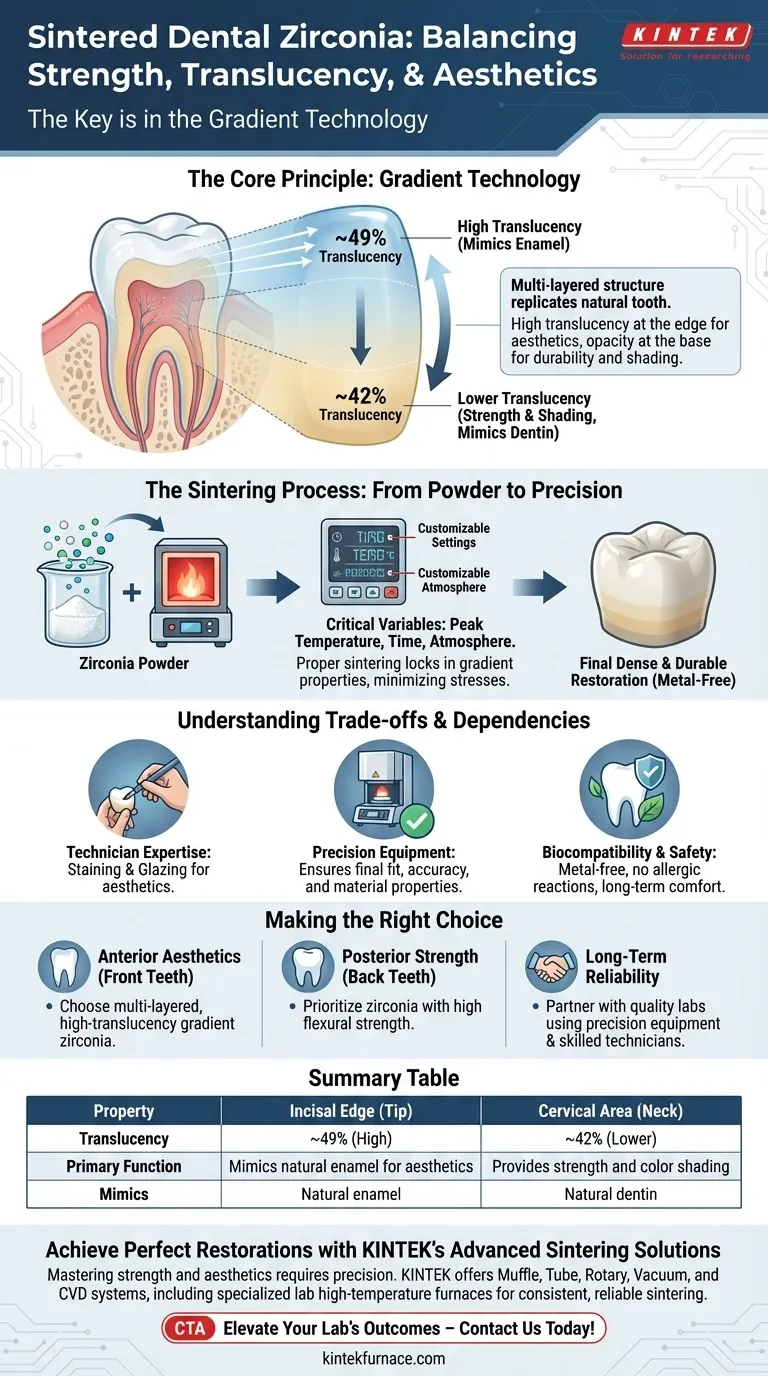

The Core Principle: Gradient Technology

Modern dental zirconia restorations are designed to replicate the complex structure of a natural tooth, which is not uniform in its composition or appearance. This is achieved through advanced gradient technology in the material itself.

Mimicking Natural Tooth Structure

A natural tooth consists of a highly translucent enamel layer covering a more opaque, yellowish dentin core. This combination gives teeth their characteristic depth and vitality.

Early zirconia was very strong but uniformly opaque, resulting in a less-than-natural appearance. Gradient zirconia solves this by building the properties of enamel and dentin directly into the restoration.

How the Translucency Gradient Works

The material is engineered with varying levels of translucency. It transitions from a higher translucency (around 49%) at the incisal tip to a lower translucency (around 42%) at the neck of the tooth.

This gradient creates an excellent incisal transparency that perfectly mimics the light transmission of natural enamel. Simultaneously, the lower light transmittance at the neck provides an effective shading effect, blocking the color of the underlying tooth structure.

The Sintering Process: From Powder to Precision

The remarkable properties of gradient zirconia are locked in during the sintering process. This highly controlled heating procedure is what fuses the zirconia particles into a final, dense, and durable restoration.

The Critical Sintering Variables

The final outcome is dictated by precise control over the sintering conditions. Key variables include the peak temperature, the duration of the heating cycle, and the atmospheric environment within the furnace.

Optimizing these factors is essential to achieving the material's intended strength and translucency gradient.

Ensuring Material Integrity

A thorough and accurate sintering cycle is critical for success. Proper sintering minimizes internal stresses and reduces the likelihood of premature failures, such as chipping or fractures, once the restoration is in service.

Modern sintering furnaces are designed for high reliability and can manage multiple phases of the process, from drying to the final sintering cycle, ensuring consistent and predictable results.

Understanding the Trade-offs and Dependencies

While the material science is advanced, the final quality of a sintered zirconia restoration is not guaranteed by the material alone. It is highly dependent on process and expertise.

Technician Skill is Paramount

The competence of the dental technician is a critical factor. An experienced professional understands how to handle the material before sintering and how to apply finishing techniques like staining or glazing to achieve the best possible aesthetic outcome.

The Quality of Equipment Matters

The precision of the sintering furnace and other digital equipment directly impacts the final fit and accuracy of the restoration. Using top-tier, temperature-controlled equipment lowers the risk of fractures and ensures the material's properties are fully realized.

Biocompatibility and Safety

The sintering process results in a final product that is metal-free, eliminating the risk of allergic reactions for sensitive patients. The controlled procedure also produces a highly durable restoration, enhancing patient comfort and long-term safety.

Making the Right Choice for Your Goal

Understanding the balance between aesthetics and function allows you to make more informed decisions for specific clinical situations.

- If your primary focus is anterior aesthetics: Choose a multi-layered, high-translucency gradient zirconia to achieve the most lifelike result that mimics natural enamel.

- If your primary focus is posterior strength: Prioritize a zirconia material known for its high flexural strength, which is essential for withstanding the forces of mastication in the back of the mouth.

- If your primary focus is long-term reliability: Partner with a dental lab that demonstrates a commitment to using high-quality materials, precision equipment, and skilled technicians.

Ultimately, mastering the use of sintered zirconia comes from understanding that its properties are the direct result of a carefully controlled and expertly executed process.

Summary Table:

| Property | Incisal Edge (Tip) | Cervical Area (Neck) |

|---|---|---|

| Translucency | ~49% (High) | ~42% (Lower) |

| Primary Function | Mimics natural enamel for aesthetics | Provides strength and color shading |

| Mimics | Natural enamel | Natural dentin |

Achieve Perfect Dental Restorations with KINTEK’s Advanced Sintering Solutions

Mastering the balance of strength and aesthetics in zirconia requires precision equipment. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, including specialized lab high-temperature furnaces for consistent, reliable sintering. All our solutions are customizable to meet your unique dental lab needs.

Elevate your lab’s outcomes—contact us today to explore how our furnaces can enhance your zirconia restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision