Proactive maintenance is the key to transforming your dental furnace from a simple tool into a consistently reliable asset. It directly prevents performance issues and error messages by detecting them early, while regular calibration ensures every firing cycle is precise. This dual approach guarantees high-quality restorations and maximizes the operational life of your equipment.

The core issue is not whether to maintain your furnace, but understanding that proactive maintenance and calibration are fundamental to protecting your investment. They safeguard the very benefits—cost savings, quality control, and productivity—that justify owning a furnace in the first place.

Why Consistent Performance is Non-Negotiable

A dental furnace is a significant capital investment intended to improve efficiency and clinical outcomes. Its value, however, is directly tied to its performance.

Protecting Your Core Investment

You invested in an in-house furnace to gain control over costs, timelines, and the final quality of restorations.

This control is only possible when the furnace operates exactly as expected, every single time. Inconsistent performance negates these benefits.

The Real Cost of a Failed Firing

A single failed or subpar restoration isn't just a material loss. It represents lost chair time, wasted technician hours, and potentially a delay in patient care.

These costs accumulate quickly and can easily surpass the expense of a regular maintenance schedule.

Ensuring Clinical and Aesthetic Excellence

The final fit, shade, and translucency of a ceramic restoration are directly dependent on achieving precise temperatures during the firing cycle.

Even minor deviations can compromise the physical and aesthetic properties of the material, leading to a result that falls short of clinical standards.

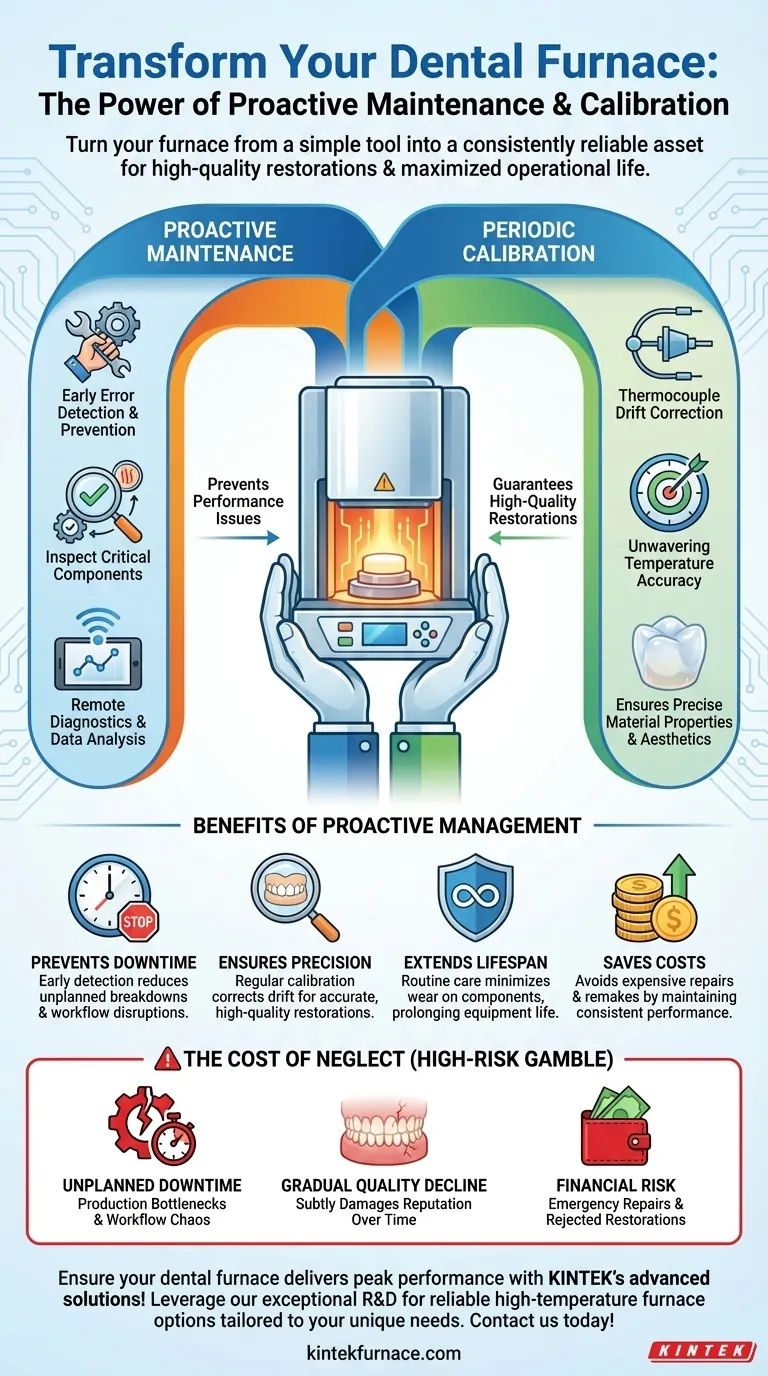

The Pillars of Proactive Furnace Management

A proactive strategy is built on two distinct but related activities: routine maintenance and periodic calibration.

Early Error Detection and Prevention

Regular maintenance allows technicians to spot and resolve potential issues before they cause a critical failure. This includes inspecting heating elements, vacuum seals, and other mechanical components.

Modern furnaces often feature remote diagnostics, allowing support technicians to analyze performance data in real time to identify subtle problems that may not yet be obvious to the user.

Unwavering Temperature Accuracy Through Calibration

A furnace's thermocouple, the sensor that measures temperature, naturally drifts over time. This is an unavoidable physical reality.

Calibration is the only process that can correct this drift, re-aligning the furnace's actual temperature with its programmed setting. Without it, you are essentially firing blind, risking weak or poorly shaded restorations.

Maximizing Equipment Lifespan

Just like any complex piece of machinery, a dental furnace benefits from regular care.

Proactive maintenance reduces wear and tear on critical components, preventing premature failures and significantly extending the functional life of the unit.

The Cost of Neglect: Understanding the Trade-offs

Choosing to defer maintenance is not a cost-saving measure; it is a high-risk gamble with predictable consequences.

The Illusion of "Saving Money"

Skipping a scheduled service saves a small, known amount of money in the short term.

However, it exposes your practice to the much larger, unknown costs of unplanned downtime, emergency repairs, and rejected restorations. The financial risk of neglect far outweighs the cost of maintenance.

The Slow Decline in Quality

Furnace performance rarely fails catastrophically overnight. Instead, it degrades slowly as the thermocouple drifts and components wear.

Without regular checks, you may experience a gradual decline in the quality of your restorations, which can subtly damage your reputation over time before a major failure makes the problem obvious.

Production Bottlenecks and Workflow Chaos

Your furnace is often a central hub in your restorative workflow. When it goes down unexpectedly, it creates an immediate bottleneck.

This disrupts scheduling for both the lab and the clinic, leading to delays and inefficiency that ripple through your entire operation.

How to Apply This to Your Practice

Your maintenance strategy should align directly with your primary business and clinical goals.

- If your primary focus is maximizing ROI: Treat proactive maintenance as a direct investment in preventing costly remakes and catastrophic downtime, which are the biggest threats to profitability.

- If your primary focus is delivering supreme clinical quality: View regular calibration as non-negotiable for achieving the precise material properties required for exceptional aesthetics and fit.

- If your primary focus is operational efficiency: Implement a rigid maintenance schedule to ensure predictable performance and prevent surprise breakdowns that disrupt your workflow.

Ultimately, consistent maintenance ensures your furnace remains a reliable partner in delivering excellent patient care.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Downtime | Early detection of issues reduces unplanned breakdowns and workflow disruptions. |

| Ensures Precision | Regular calibration corrects temperature drift for accurate, high-quality restorations. |

| Extends Lifespan | Routine care minimizes wear on components, prolonging equipment life. |

| Saves Costs | Avoids expensive repairs and remakes by maintaining consistent performance. |

Ensure your dental furnace delivers peak performance with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnace options, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability tailors solutions to your unique needs, enhancing efficiency and quality. Don't let maintenance issues hold you back—contact us today to learn how we can support your practice with precision and reliability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations