At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) achieves excellent film uniformity through a combination of two factors: precise, real-time control over the chemical environment and a deposition mechanism that is inherently diffusive, not line-of-sight. This allows reactive gas species to evenly coat a substrate, including complex, three-dimensional surfaces.

The key to understanding PECVD uniformity is to see it not as a simple spraying process, but as the creation of a controlled, reactive "atmosphere." The plasma energizes precursor gases, allowing them to diffuse and settle uniformly across a surface, rather than being directionally shot at it.

The Two Pillars of PECVD Uniformity

Achieving a uniform film is not accidental; it is the result of deliberate control over the process environment and the physical design of the deposition chamber. These two elements work in concert to ensure every part of the substrate experiences nearly identical conditions.

Pillar 1: Precision Control Over the Process Environment

The foundation of a uniform film is a stable and repeatable environment. PECVD systems allow for exacting control over several critical parameters that directly influence how film precursors behave.

- Gas Flow and Pressure: Regulating the flow rate and pressure of precursor gases ensures a consistent concentration of reactants is available across the entire substrate. This directly impacts the deposition rate and material composition.

- Temperature: A uniform temperature profile across the substrate holder is crucial. Temperature affects the surface mobility of deposited atoms, allowing them to arrange into a stable, even film structure.

- Plasma Power: The radio frequency (RF) power applied to create the plasma determines the reactivity of the gas precursors. Stable power ensures a consistent density of reactive species, leading to a predictable deposition rate.

Controlling these factors optimizes the mean free path—the average distance a particle travels before colliding with another—ensuring reactive species are distributed evenly rather than clustering in one area.

Pillar 2: Advanced Reactor Engineering

The physical hardware of the PECVD system is designed specifically to promote uniformity.

- Uniform Gas Distribution: Modern PECVD reactors utilize sophisticated "showerhead" designs. These components introduce precursor gases through thousands of tiny, strategically placed holes, ensuring the gas mixture is delivered evenly over the substrate's surface.

- Optimized Temperature Profiles: The substrate heater, or chuck, is engineered to maintain a highly uniform temperature. This prevents "hot spots" or "cold spots" that would otherwise cause variations in film thickness and quality.

Beyond Flat Surfaces: The Conformality Advantage

Perhaps the most significant advantage of PECVD, especially when compared to other methods like Physical Vapor Deposition (PVD), is its ability to produce highly conformal coatings.

Diffusive vs. Line-of-Sight Deposition

Think of PVD as spray painting. The paint travels in a straight line from the nozzle to the object. If a part of the object is in shadow or behind another feature, it won't get coated. This is a line-of-sight process.

PECVD, on the other hand, is more like immersing an object in a thick, reactive fog. The energized gas particles are not traveling in one direction but are diffusing throughout the entire chamber. This diffusive, gas-driven process allows them to wrap around features and coat all surfaces, including the inside of trenches or holes.

How Plasma Achieves High Conformality

The plasma breaks down stable precursor gases into highly reactive, but short-lived, species. These species diffuse throughout the chamber and adsorb onto all exposed surfaces. Because their movement is random and not directional, they can uniformly reach and coat complex, non-flat topographies, resulting in a film of consistent thickness everywhere.

Understanding the Trade-offs

While powerful, PECVD is not without its complexities. Achieving its benefits requires a clear understanding of the process variables.

The Complexity of Parameter Tuning

The high degree of control is also a source of complexity. Finding the optimal "recipe" of gas flow, pressure, power, and temperature for a specific material and substrate can require significant process development and experimentation.

Deposition Rate vs. Film Quality

There is often a trade-off between the speed of deposition and the final quality of the film. Increasing plasma power or gas flow might increase the deposition rate, but it can sometimes compromise uniformity or create stress in the film if not managed carefully.

Adhesion as a Related Benefit

The plasma in a PECVD process does more than just create reactive species; it also treats the substrate surface. This plasma activation cleans the surface and creates bonding sites, leading to exceptionally strong film adhesion. While distinct from uniformity, this is a critical quality for producing a durable and reliable coating.

Making the Right Choice for Your Goal

Your specific application will determine which aspects of the PECVD process are most important to control.

- If your primary focus is coating complex, non-flat topographies: PECVD's diffusive, non-line-of-sight nature is your most critical advantage.

- If your primary focus is achieving maximum thickness uniformity on a flat substrate: Your efforts should concentrate on optimizing the showerhead gas distribution and the chuck's temperature profile.

- If your primary focus is reproducibility across hundreds of runs: The stability and precise electronic control of your system's gas flow, pressure, and RF power are paramount.

By understanding these core principles, you can effectively leverage PECVD to produce high-quality, uniform films tailored to your specific needs.

Summary Table:

| Key Factor | Role in Uniformity |

|---|---|

| Gas Flow & Pressure | Ensures consistent reactant concentration and deposition rate |

| Temperature | Promotes surface mobility for stable, even film formation |

| Plasma Power | Maintains reactive species density for predictable deposition |

| Reactor Design | Uses showerheads and heaters for uniform gas and temperature distribution |

| Diffusive Process | Enables non-line-of-sight coating of complex topographies |

Ready to achieve unparalleled film uniformity in your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including our specialized CVD/PECVD Systems. With strong deep customization capabilities, we tailor our products—such as Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces—to precisely meet your unique experimental needs. Contact us today to enhance your coating processes and drive innovation!

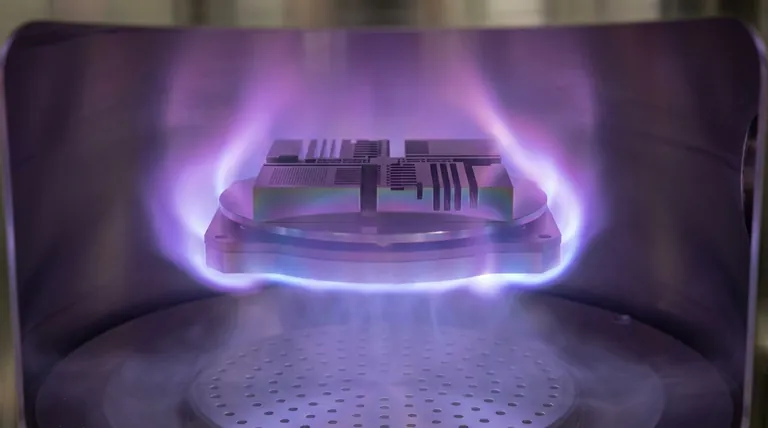

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition