At its core, automation and intelligent control transform Chemical Vapor Deposition (CVD) from a complex, operator-dependent art into a precise and repeatable science. By implementing advanced control systems, a CVD furnace can meticulously manage reaction conditions, monitor the process in real time, and automatically adjust parameters. This leads directly to a more efficient, stable, and reliable process for creating high-quality thin films.

The fundamental advantage of an automated CVD furnace is not merely convenience, but the systematic elimination of process variability. This ensures that every deposition run is executed with a level of precision and consistency that is unattainable through manual operation, directly improving film quality and yield.

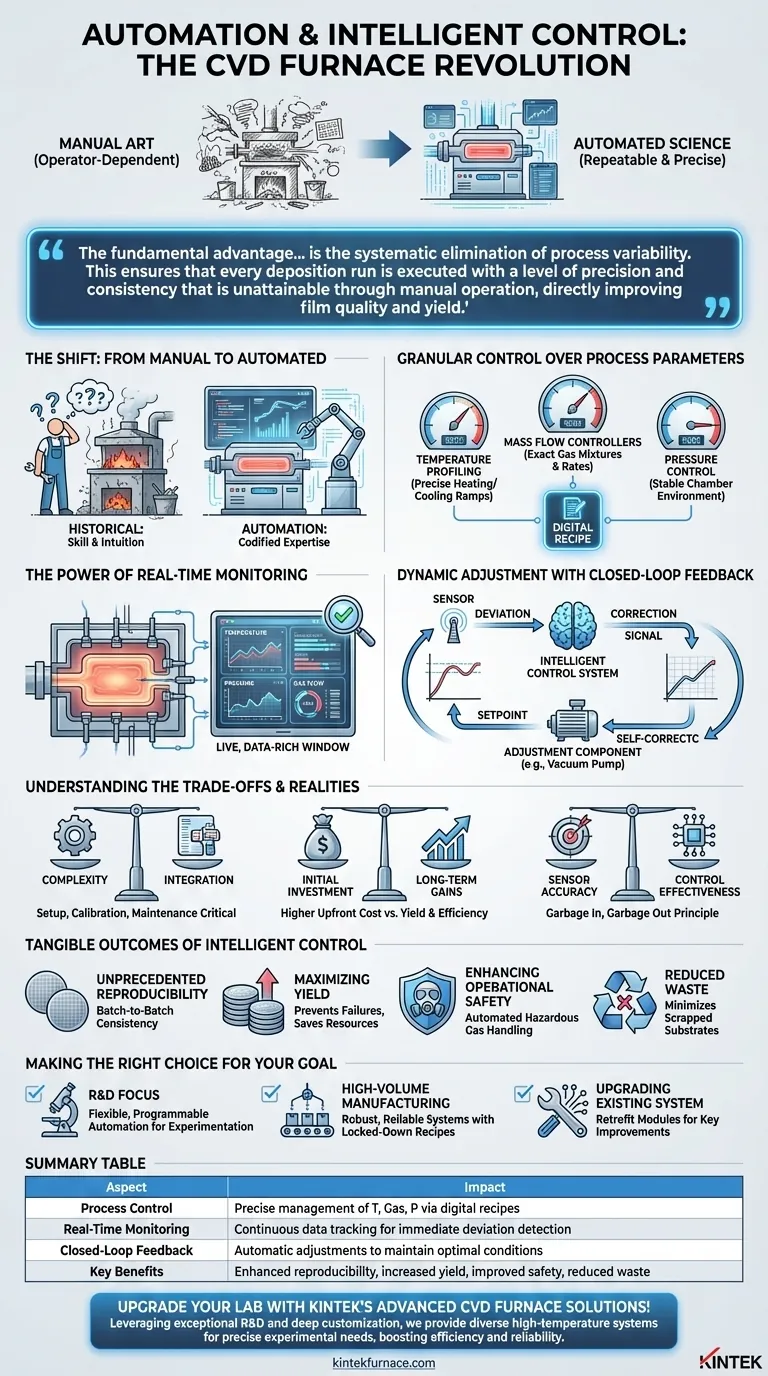

The Shift from Manual Art to Automated Science

Historically, achieving consistent results with CVD relied heavily on the skill and intuition of an experienced operator. Automation fundamentally changes this dynamic by codifying expertise into a reliable, software-driven process.

Granular Control Over Process Parameters

Modern control systems allow you to define and execute a precise "digital recipe" for your thin film. This ensures every critical variable is managed with pinpoint accuracy.

Key parameters under automated control include temperature profiling, which manages precise heating and cooling ramps, and mass flow controllers, which guarantee exact gas mixtures and flow rates. It also includes pressure control, maintaining a stable environment inside the reaction chamber.

The Power of Real-Time Monitoring

Intelligent control provides a live, data-rich window into the deposition process as it happens. This is a stark contrast to discovering a failed run only after the process is complete.

Sensors constantly feed data back to the control system, tracking temperature, pressure, and gas flow. This continuous data stream allows for immediate identification of any deviation from the programmed recipe.

Dynamic Adjustment with Closed-Loop Feedback

This is where "intelligent" control truly comes into play. The system doesn't just monitor; it actively corrects itself.

When a sensor detects a deviation—for instance, a slight drop in chamber pressure—a closed-loop feedback system automatically adjusts the relevant component, like a vacuum pump, to bring the parameter back to its setpoint. This self-correction happens instantly and without human intervention.

Understanding the Trade-offs and Realities

While the benefits are significant, adopting advanced automation requires a clear-eyed understanding of its implications. Objectivity demands we acknowledge the potential challenges.

The Complexity of Integration

An automated CVD system is more than a simple furnace; it is an integrated suite of hardware and software. Proper setup, calibration, and maintenance are critical for reliable operation.

The Initial Investment

Furnaces equipped with advanced automation and control systems carry a higher upfront cost than their manual or semi-automated counterparts. This investment must be weighed against the long-term gains in yield, material savings, and labor efficiency.

Dependence on Sensor Accuracy

The entire control system's effectiveness hinges on the quality and calibration of its sensors. An inaccurate sensor will cause the system to make incorrect adjustments, potentially compromising the process. The principle of "garbage in, garbage out" applies directly.

Tangible Outcomes of Intelligent Control

Ultimately, the technical features of automation are only valuable because of the concrete process improvements they deliver.

Achieving Unprecedented Reproducibility

By removing human error and environmental variables, automated recipes ensure that the film deposited today is identical to the one deposited next month. This batch-to-batch consistency is critical for both manufacturing and credible scientific research.

Maximizing Yield and Minimizing Waste

Real-time monitoring and self-correction prevent process failures that would otherwise result in scrapped substrates. This dramatically increases process yield, saving valuable time, energy, and expensive precursor materials.

Enhancing Operational Safety

Many CVD processes involve hazardous, flammable, or toxic gases. Automation manages the handling, delivery, and purging of these materials according to pre-programmed safety protocols, significantly reducing risk to operators.

Making the Right Choice for Your Goal

The level of automation you require depends entirely on your primary objective. Use these guidelines to inform your decision.

- If your primary focus is research and development (R&D): Prioritize systems with flexible, highly programmable automation that allows for easy experimentation and fine-tuning of deposition parameters.

- If your primary focus is high-volume manufacturing: Emphasize robust, reliable systems with locked-down recipes and comprehensive data logging to ensure maximum reproducibility and process control.

- If your primary focus is upgrading an existing system: Focus on retrofitting key modules, such as mass flow controllers and integrated pressure sensors, to gain the most significant improvements in process stability for your investment.

By embracing automation, you shift your focus from manually managing the process to strategically optimizing the outcome.

Summary Table:

| Aspect | Impact |

|---|---|

| Process Control | Precise management of temperature, gas flow, and pressure via digital recipes |

| Real-Time Monitoring | Continuous data tracking for immediate deviation detection |

| Closed-Loop Feedback | Automatic adjustments to maintain optimal conditions |

| Key Benefits | Enhanced reproducibility, increased yield, improved safety, and reduced waste |

Upgrade your lab with KINTEK's advanced CVD furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like CVD/PECVD, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures precise alignment with your unique experimental needs, boosting efficiency and reliability. Contact us today to discuss how we can enhance your operations!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis