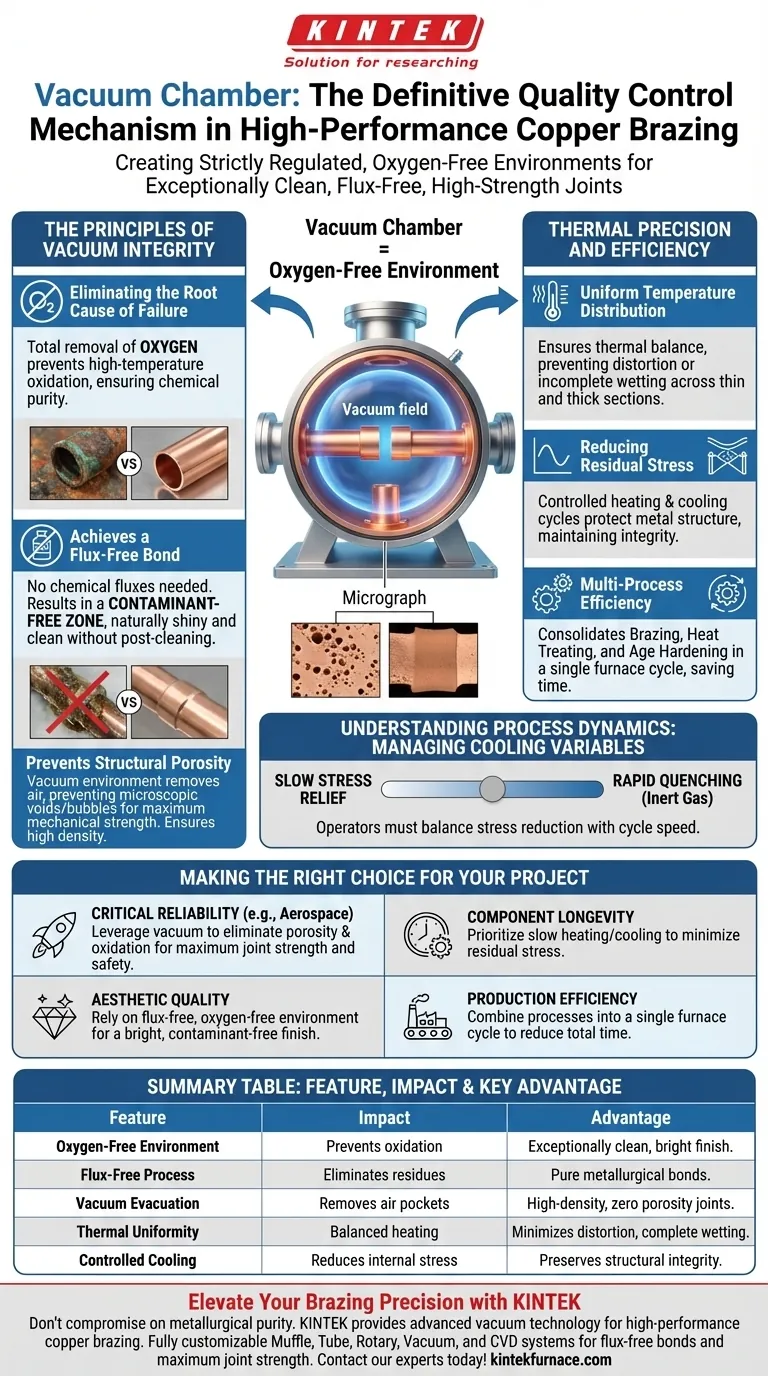

A vacuum chamber acts as the definitive quality control mechanism in high-performance copper brazing by creating a strictly regulated, oxygen-free environment. This evacuation of air eliminates the risk of high-temperature oxidation, enabling the creation of exceptionally clean, flux-free, and high-strength joints that are free from porosity.

The vacuum environment shifts the brazing process from simple metal joining to precision metallurgical engineering. By removing contaminants and controlling thermal stress, it ensures the reliability required for critical industries like aerospace.

The Principles of Vacuum Integrity

Eliminating the Root Cause of Failure

The primary function of the vacuum chamber is the total removal of oxygen. At brazing temperatures, the presence of oxygen invariably leads to metal oxidation, which compromises the joint.

By evacuating the air, the system prevents this chemical reaction entirely. This protection is not superficial; it ensures the metal remains chemically pure throughout the joining process.

Achieving a Flux-Free Bond

Because oxidation is physically impossible in a vacuum, there is no need for chemical fluxes. Flux is typically used to clean metals during brazing, but it can leave corrosive residues or inclusions.

Vacuum brazing removes this variable, resulting in a contaminant-free zone. This yields a finish that is naturally shiny, bright, and exceptionally clean without post-process cleaning.

Preventing Structural Porosity

The reliability of a copper joint depends on its density. The vacuum environment is essential for preventing porosity—microscopic voids or bubbles within the braze alloy.

Eliminating these voids ensures the joint achieves maximum mechanical strength. This makes the process the preferred solution for applications where seal integrity and load-bearing capacity are non-negotiable.

Thermal Precision and Efficiency

Uniform Temperature Distribution

High-performance brazing requires more than just heat; it requires thermal balance. The vacuum furnace environment facilitates better uniformity of temperature across all metal parts.

This ensures that thin and thick sections of a component reach the brazing temperature simultaneously, preventing distortion or incomplete wetting.

Reducing Residual Stress

The process utilizes controlled heating and cooling cycles to protect the metal's structure. By heating and cooling the metal slowly, the vacuum process significantly reduces residual stress.

This controlled thermal ramp helps the metals maintain their structural integrity and original strength properties after the process is complete.

Multi-Process Efficiency

A vacuum chamber allows for high-volume process consolidation. Brazing, heat treating, and age hardening can often be performed in a single furnace cycle.

This capability streamlines production, saving significant time while ensuring that the metallurgical properties of the copper are optimized in one continuous operation.

Understanding the Process Dynamics

Managing Cooling Variables

While the vacuum environment excels at slow, stress-relieving cooling, some applications require rapid temperature drops.

Operators must balance stress reduction with cycle speed. Some systems address this via quenching, using an inert gas like Argon to cool parts quickly. Understanding whether your component requires slow stress relief or rapid quenching is critical to the process setup.

Making the Right Choice for Your Project

The value of vacuum brazing depends on the specific demands of your application.

- If your primary focus is Critical Reliability (e.g., Aerospace): Leverage the vacuum process to eliminate porosity and oxidation, ensuring maximum joint strength and safety.

- If your primary focus is Component Longevity: Prioritize the slow heating and cooling cycles to minimize residual stress and maintain the base metal's integrity.

- If your primary focus is Aesthetic Quality: Rely on the flux-free, oxygen-free environment to produce parts with a bright, shiny, and contaminant-free finish.

- If your primary focus is Production Efficiency: Utilize the ability to combine brazing, heat treating, and hardening into a single furnace cycle to reduce total processing time.

The vacuum chamber is not just a heating vessel; it is a tool for guaranteeing metallurgical purity.

Summary Table:

| Feature | Impact on Brazing Quality | Key Advantage |

|---|---|---|

| Oxygen-Free Environment | Prevents high-temperature oxidation | Exceptionally clean, bright, and shiny finish |

| Flux-Free Process | Eliminates corrosive chemical residues | Pure metallurgical bonds without post-cleaning |

| Vacuum Evacuation | Removes microscopic air pockets | High-density joints with zero structural porosity |

| Thermal Uniformity | Balanced heating across all sections | Minimizes distortion and ensures complete wetting |

| Controlled Cooling | Reduces internal residual stress | Preserves structural integrity and metal strength |

Elevate Your Brazing Precision with KINTEK

Don't compromise on metallurgical purity. Whether you are serving the aerospace, medical, or energy sectors, KINTEK provides the advanced vacuum technology required for high-performance copper brazing.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. All our lab high-temperature furnaces are fully customizable to meet your unique materials processing needs, ensuring flux-free bonds and maximum joint strength every time.

Ready to optimize your thermal processing? Contact our engineering experts today to find the perfect customizable solution for your laboratory or production line.

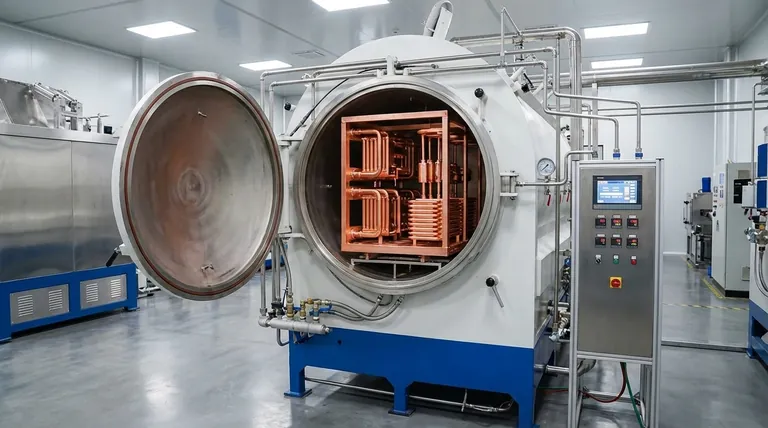

Visual Guide

References

- Er. RoshanY. Gonnade. Copper Brazing Technology. DOI: 10.22214/ijraset.2025.73740

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the biomedical applications of high-temperature vacuum furnaces? Essential for Safe, Biocompatible Medical Implants

- How does vacuum annealing and tempering improve material properties? Enhance Strength, Purity, and Durability

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality

- What is a vacuum sintering furnace? Achieve High-Purity, Dense Materials

- Why is a vacuum annealing furnace superior to air annealing for ZnSe/SiO2/Si? Protect Your Semiconductor Integrity

- Why is a multi-stage vacuum evaporation system utilized in FMDS treatment? Maximize Efficiency and Resource Recovery

- What are the technical advantages of vacuum Spark Plasma Sintering (SPS) systems? Advanced SiC Ceramic Densification

- What is the function of a vacuum austenitizing furnace for SCM440 steel? Achieve Precision Heat Treatment