In the biomedical field, high-temperature vacuum furnaces are essential for manufacturing and enhancing medical devices intended for use inside the human body. Their primary function is to create materials and surfaces with exceptional purity, strength, and biocompatibility by processing them in a controlled, contaminant-free environment. These furnaces enable critical processes like sintering, brazing, and coating of implants such as artificial joints, heart valves, and dental hardware.

The core value of a vacuum furnace in biomedical applications is not just the high heat, but the elimination of atmospheric gases. This prevents oxidation and contamination, ensuring that implants are non-reactive, safe, and will not be rejected by the body.

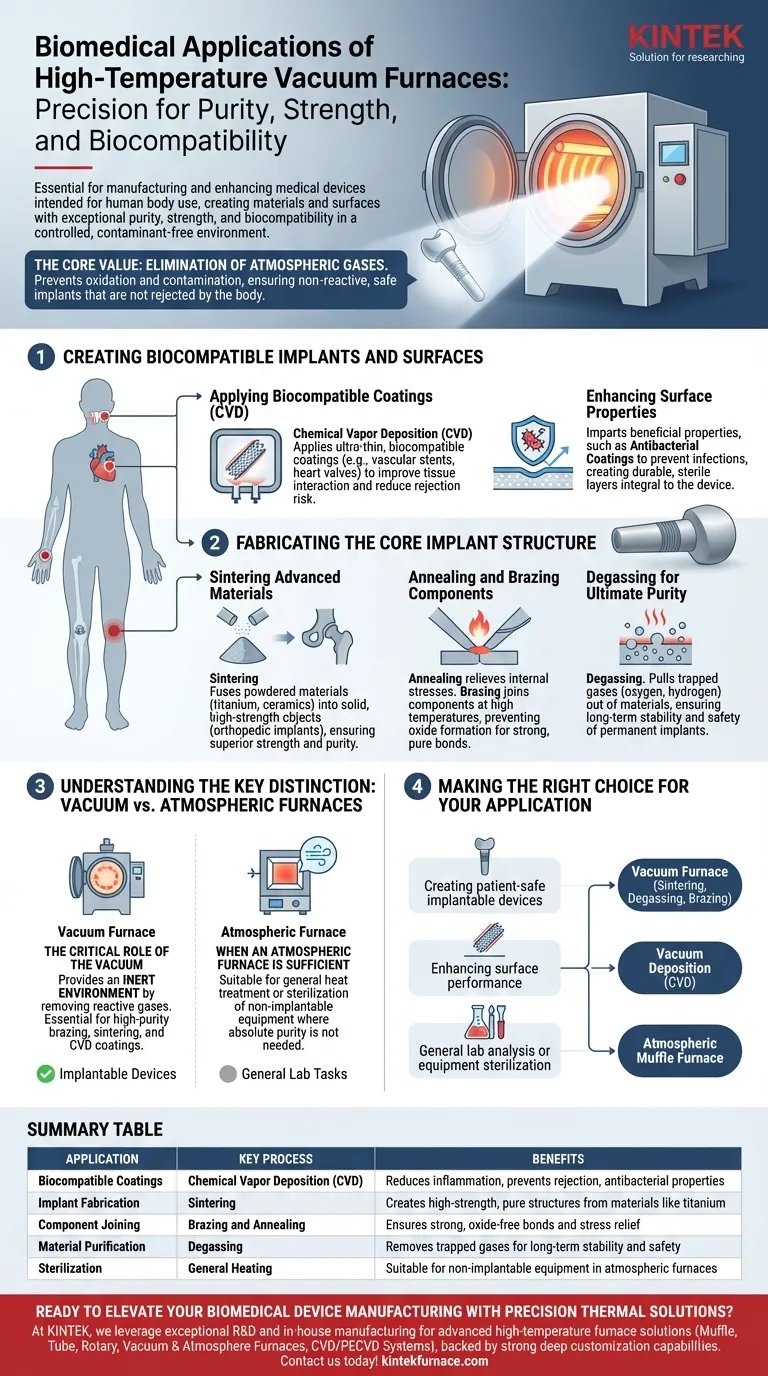

Creating Biocompatible Implants and Surfaces

The central challenge for any medical implant is ensuring the body accepts it without triggering an inflammatory response or rejection. High-temperature vacuum furnaces are the primary tool for solving this problem at the material level.

Applying Biocompatible Coatings

Many advanced medical devices, like vascular stents and artificial heart valves, are coated with a thin film to improve their interaction with biological tissue.

A process called Chemical Vapor Deposition (CVD) is performed in a vacuum furnace to apply these ultra-thin, biocompatible coatings. This layer acts as an interface between the device and the body, drastically reducing the risk of inflammation and rejection post-implantation.

Enhancing Surface Properties

Beyond simple biocompatibility, furnace processes can impart specific beneficial properties to an implant's surface.

Coatings can be designed to be antibacterial, preventing infections that can lead to implant failure. The high-temperature process creates a durable, sterile layer that is integral to the device itself.

Fabricating the Core Implant Structure

High-temperature vacuum furnaces are not just for surface treatments; they are often used to create the very structure of the implant itself, ensuring it has the required mechanical strength and material purity.

Sintering Advanced Materials

Sintering is a process where powdered materials, such as titanium or specialized ceramics, are heated in a vacuum until their particles fuse together into a solid, high-strength object.

This is a common method for producing the final shape of orthopedic implants like hip and knee joints. The vacuum ensures the final product has superior strength and is free from impurities that could compromise its integrity.

Annealing and Brazing Components

Annealing involves heating a material to relieve internal stresses created during manufacturing, preventing cracks and failure under load. Brazing uses a filler metal to join multiple components together at high temperatures.

Performing these processes in a vacuum is critical for complex implants. It prevents the formation of oxides on the joints, resulting in a bond that is as strong and pure as the base materials themselves.

Degassing for Ultimate Purity

Materials, especially metals, often contain trapped gases like oxygen and hydrogen. When heated, these gases can create microscopic voids that weaken the material or react with bodily fluids.

A key function of the vacuum is degassing, which pulls these trapped gases out of the material during the heating cycle. This purification step is non-negotiable for ensuring the long-term stability and safety of a permanent implant.

Understanding the Key Distinction: Vacuum vs. Atmospheric Furnaces

Not all high-temperature processes in the biomedical field require a vacuum. Understanding the difference is key to selecting the right tool for the job.

The Critical Role of the Vacuum

For any process involving implantable devices, a vacuum is essential. It provides an inert environment by removing reactive gases like oxygen. This prevents the formation of oxide layers that can compromise biocompatibility and structural integrity.

The vacuum environment is what makes processes like high-purity brazing, sintering of titanium, and CVD coatings possible.

When an Atmospheric Furnace is Sufficient

Simpler laboratory tasks, such as the general sterilization of non-implantable equipment or basic materials analysis, can often be performed in an atmospheric furnace (like a muffle furnace).

These furnaces are suitable when the primary goal is heat treatment or sterilization, and the absolute purity and non-reactivity required for an implantable device are not necessary.

Making the Right Choice for Your Application

Selecting the correct thermal processing technology depends entirely on the end goal and the level of material purity required.

- If your primary focus is creating patient-safe implantable devices: A high-temperature vacuum furnace is non-negotiable for processes like sintering, degassing, and brazing.

- If your primary focus is enhancing surface performance: Vacuum deposition (CVD) is the definitive method for applying the pure, biocompatible, and functional coatings required for advanced devices.

- If your primary focus is general lab analysis or equipment sterilization: An atmospheric muffle furnace is often a sufficient and more cost-effective choice for tasks that do not demand an inert environment.

Ultimately, the precise control offered by high-temperature vacuum furnaces is foundational to the safety and innovation of modern medical implants.

Summary Table:

| Application | Key Process | Benefits |

|---|---|---|

| Biocompatible Coatings | Chemical Vapor Deposition (CVD) | Reduces inflammation, prevents rejection, antibacterial properties |

| Implant Fabrication | Sintering | Creates high-strength, pure structures from materials like titanium |

| Component Joining | Brazing and Annealing | Ensures strong, oxide-free bonds and stress relief |

| Material Purification | Degassing | Removes trapped gases for long-term stability and safety |

| Sterilization | General Heating | Suitable for non-implantable equipment in atmospheric furnaces |

Ready to elevate your biomedical device manufacturing with precision thermal solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're developing biocompatible implants or enhancing surface properties, our expertise ensures superior purity, strength, and performance. Contact us today to discuss how we can support your innovation and deliver reliable results for your laboratory!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion