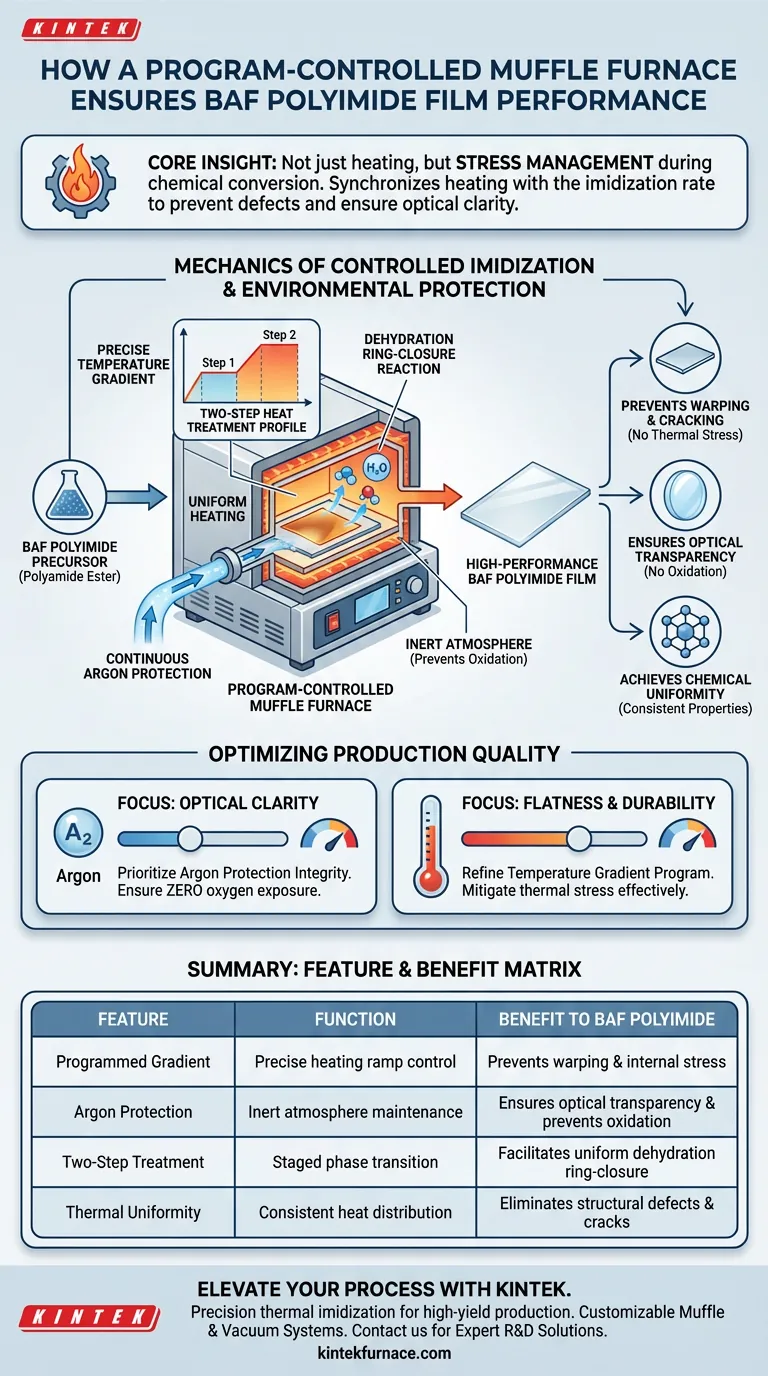

A program-controlled muffle furnace ensures the performance of BAF polyimide films by orchestrating a precise environment for the chemical conversion of the material. By maintaining a strict temperature gradient under continuous argon protection, the furnace manages the delicate dehydration ring-closure reaction required to transform polyamide ester into high-quality polyimide.

Core Insight: The primary function of the furnace is not just heating, but stress management during chemical conversion. By synchronizing the rate of heating with the rate of the imidization reaction, the equipment prevents physical defects like warping while ensuring the optical clarity required for transparent films.

The Mechanics of Controlled Imidization

To understand how the furnace ensures performance, one must look at how it handles the chemical transition of the material.

Facilitating the Two-Step Heat Treatment

The furnace is programmed to execute a specific two-step heat treatment profile. This staged approach allows the material to undergo necessary phase changes without being subjected to sudden thermal shock.

Inducing the Ring-Closure Reaction

The core objective of this thermal process is the dehydration ring-closure reaction. This chemical shift converts the precursor polyamide ester into the final polyimide structure, establishing the material's fundamental properties.

Ensuring Chemical Uniformity

By strictly controlling the ramp rate, the furnace ensures this reaction happens uniformly throughout the film. If the reaction occurs unevenly, the molecular structure becomes inconsistent, degrading the film's final performance.

Environmental Stability and Protection

Performance is not just about temperature; it is about maintaining a pristine reaction environment.

Continuous Argon Protection

The furnace operates under a continuous flow of argon gas. This inert atmosphere is critical because it prevents oxygen from interacting with the film during high-temperature processing.

Preserving Optical Transparency

For BAF polyimide films, which are often valued for their transparency, oxidation is a major failure mode. The argon shield prevents discoloration and ensures the film remains optically clear.

Managing Thermal Stress

The most common physical defects in film production—warping and cracking—are direct results of poor thermal management.

Precise Temperature Gradients

A "program-controlled" system allows for precise temperature gradient control. This means the temperature rises and stabilizes exactly according to the material's tolerance, rather than fluctuating randomly.

Preventing Structural Defects

By eliminating hot spots and rapid cooling, the furnace prevents uneven thermal stress. This is the specific mechanism that stops the film from warping or cracking during the curing process.

Understanding Process Sensitivities

While a program-controlled furnace is a powerful tool, it relies on strict adherence to process parameters.

Sensitivity to Gradient Deviation

If the programmed temperature gradient is too aggressive, the rate of dehydration may exceed the material's ability to relax. This leads to internal stress accumulation, regardless of the equipment's precision.

The Necessity of Atmosphere Integrity

The performance of the film is entirely dependent on the purity and flow rate of the argon. Even a momentary interruption in gas flow can introduce oxidation, permanently compromising the transparency of the BAF film.

Optimizing Film Production Quality

To maximize the performance of your BAF polyimide films, tailor your furnace usage to your specific quality metrics.

- If your primary focus is Optical Clarity: Prioritize the integrity of the argon protection system to ensure zero exposure to oxygen during the heating cycle.

- If your primary focus is Flatness and Durability: Focus on refining the temperature gradient program to ensure the heating rate effectively mitigates thermal stress during the ring-closure phase.

By leveraging the precise control of the muffle furnace, you turn a volatile chemical reaction into a predictable, high-yield manufacturing process.

Summary Table:

| Feature | Function in Imidization | Benefit to BAF Polyimide |

|---|---|---|

| Programmed Gradient | Precise heating ramp control | Prevents warping and internal stress |

| Argon Protection | Inert atmosphere maintenance | Ensures optical transparency and prevents oxidation |

| Two-Step Treatment | Staged phase transition | Facilitates uniform dehydration ring-closure |

| Thermal Uniformity | Consistent heat distribution | Eliminates structural defects and cracks |

Elevate Your Advanced Material Processing with KINTEK

Precision in thermal imidization is the difference between a high-yield product and a failed batch. KINTEK provides industry-leading muffle and vacuum systems specifically engineered to handle the rigorous demands of BAF polyimide film production.

Why partner with KINTEK?

- Expert R&D & Manufacturing: Our systems are built for precise temperature gradient management and inert gas integrity.

- Customizable Solutions: From muffle and tube furnaces to CVD systems, we tailor our high-temp lab equipment to your specific material needs.

- Process Reliability: Minimize thermal stress and maximize optical clarity with our specialized argon-flow control technology.

Ready to optimize your lab’s heat treatment efficiency? Contact KINTEK today to discuss your unique project needs and discover how our customizable high-temperature solutions can transform your production quality.

Visual Guide

References

- Soluble Photosensitive Polyimide Precursor with Bisphenol A Framework: Synthesis and Characterization. DOI: 10.3390/polym17111428

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a box-type resistance furnace in GFRP studies? Mastering High-Temperature Material Simulation

- What is a muffle furnace and how does it differ from a vacuum furnace? Choose the Right High-Temperature Solution

- How does a muffle furnace contribute to energy efficiency? Achieve Cost Savings and Precise Heating

- How does a muffle furnace differ from a pusher furnace? Choose the Right Furnace for Your Lab

- How is a laboratory Muffle furnace utilized in the heat treatment of DP steel? Optimize Martensite & Strength

- What role does a high-temperature box furnace play in the pre-calcination of LLZTO? Master Garnet Phase Synthesis

- What are the key technologies used in the muffle furnace for annealing silicon-based materials? Precision Control for Superior Results

- What was the initial purpose of a muffle furnace and how has it evolved? Discover Its Journey from Contamination Shield to Precision Tool