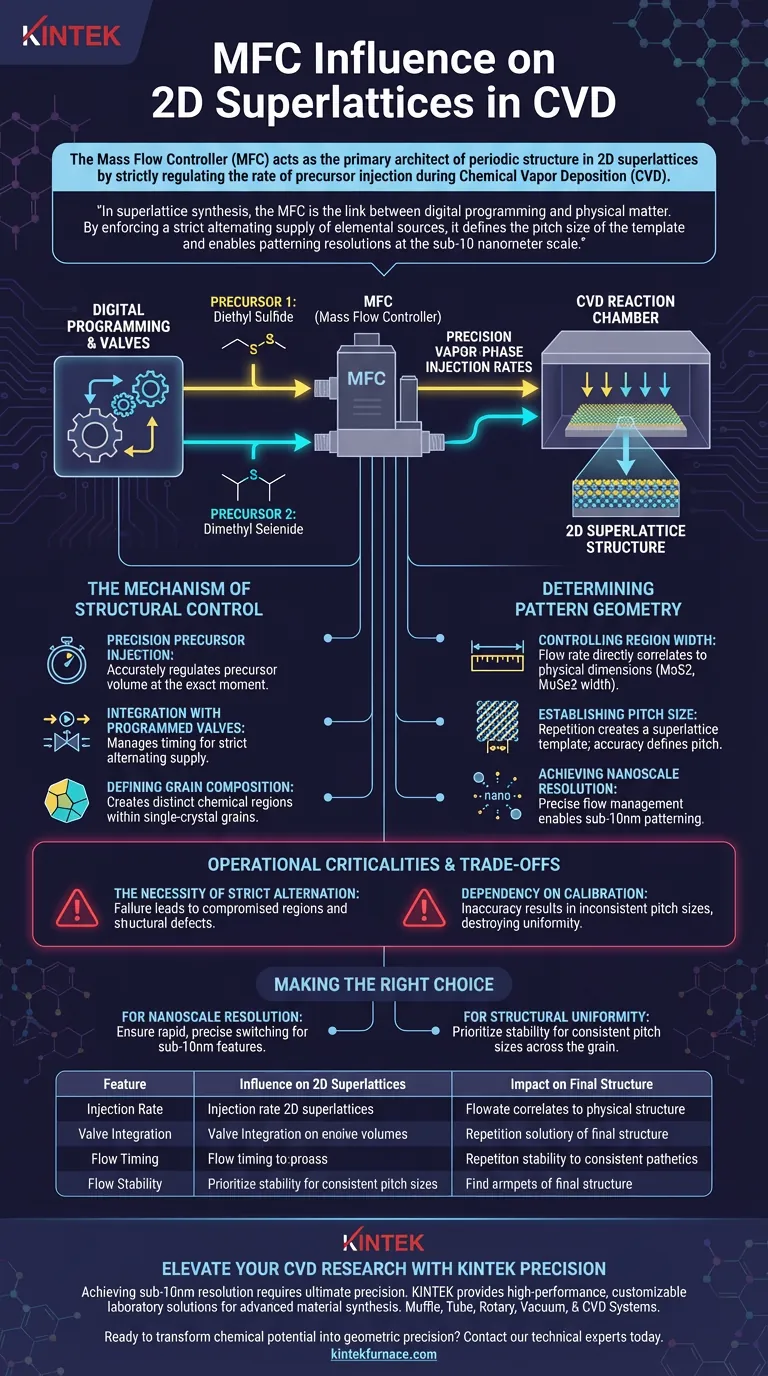

The Mass Flow Controller (MFC) acts as the primary architect of periodic structure in 2D superlattices by strictly regulating the rate of precursor injection. During chemical vapor deposition, the MFC governs the supply of vapors like diethyl sulfide and dimethyl selenide, directly determining the width and periodicity of the resulting crystal regions.

In superlattice synthesis, the MFC is the link between digital programming and physical matter. By enforcing a strict alternating supply of elemental sources, it defines the pitch size of the template and enables patterning resolutions at the sub-10 nanometer scale.

The Mechanism of Structural Control

Precision Precursor Injection

The fundamental role of the MFC is the precise regulation of vapor-phase injection rates.

In the synthesis of materials like MoS2 and MoSe2, the MFC ensures that the specific amount of chemical precursor enters the system at the exact moment it is required.

Integration with Programmed Valves

The MFC does not operate in isolation; it is integrated with programmed valves to manage the timing of the supply.

This combination allows for a "strict alternating supply" of different elemental sources.

Defining Grain Composition

By switching between sources such as diethyl sulfide and dimethyl selenide, the system creates distinct chemical regions within single-crystal grains.

The MFC ensures that the transition between these chemical sources is controlled and deliberate.

Determining Pattern Geometry

Controlling Region Width

The flow rate managed by the MFC directly correlates to the physical dimensions of the material.

By adjusting the flow intensity and duration, the MFC controls the specific width of the MoS2 and MoSe2 regions.

Establishing Pitch Size

The repetition of these alternating regions creates a periodic structure known as the superlattice template.

The accuracy of the MFC's flow management determines the pitch size, which is the distance between recurring features in the pattern.

Achieving Nanoscale Resolution

The ultimate capability provided by this setup is high-resolution patterning.

With precise flow management, researchers can achieve patterning resolutions at the sub-10 nanometer scale, pushing the boundaries of material miniaturization.

Operational Criticalities and Trade-offs

The Necessity of Strict alternation

The system relies entirely on the strict alternating supply of precursors.

If the MFC or valve integration fails to switch sources cleanly, the definition of the MoS2 and MoSe2 regions will be compromised, leading to structural defects.

Dependency on Calibration

The ability to achieve sub-10 nanometer resolution implies a zero-tolerance policy for flow drift.

Any inaccuracy in the MFC's regulation of the vapor-phase precursors will result in inconsistent pitch sizes, destroying the periodic uniformity of the superlattice.

Making the Right Choice for Your Goal

To optimize your superlattice synthesis, consider your specific structural requirements:

- If your primary focus is Nanoscale Resolution: Ensure your MFC and valve integration are capable of rapid, precise switching to define features at the sub-10 nanometer scale.

- If your primary focus is Structural Uniformity: Prioritize the stability of the MFC's regulation to maintain consistent pitch sizes across the entire single-crystal grain.

Ultimately, the Mass Flow Controller transforms chemical potential into geometric precision.

Summary Table:

| Feature | Influence on 2D Superlattices | Impact on Final Structure |

|---|---|---|

| Injection Rate | Regulates vapor-phase precursor volume | Determines width of MoS2/MoSe2 regions |

| Valve Integration | Enables strict alternating supply cycles | Creates distinct chemical regions in grains |

| Flow Timing | Controls exposure duration per source | Establishes the superlattice pitch size |

| Flow Stability | Prevents drift in chemical delivery | Achieves sub-10nm patterning resolution |

Elevate Your CVD Research with KINTEK Precision

Achieving sub-10nm resolution in 2D superlattices requires the ultimate precision in precursor management. KINTEK provides high-performance laboratory solutions tailored for advanced material synthesis. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique experimental needs.

Ready to transform chemical potential into geometric precision? Contact our technical experts today to design a high-temperature furnace system that delivers the stability and control your research demands.

Visual Guide

References

- Jeongwon Park, Kibum Kang. Area-selective atomic layer deposition on 2D monolayer lateral superlattices. DOI: 10.1038/s41467-024-46293-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is the operating principle of a Quartz Crystal Thickness Monitor? Achieve Precise ZTO Thin Film Control

- How does Chemical Vapor Deposition (CVD) differ from Physical Vapor Deposition (PVD)? Choose the Right Thin-Film Process

- What are the economic advantages of an integrated CVD carbonization system? Save 90% in Production Time

- In which industry is CVD frequently used, and for what specific application? Discover Its Role in Semiconductors and Beyond

- How does a CVD system precisely control InN nanowire growth? Expert Secrets to High-Quality Synthesis

- What are the disadvantages of CVD? Weighing High Costs, Complexity, and Constraints

- What is the function of the high-purity quartz furnace tube in LP-CVD? Enhance Your SLG Synthesis Quality

- How does deposition occur on the substrate in CVD? Master Thin Film Growth with Precision Control