At its core, a horizontal electric furnace achieves precise thermal control through a sophisticated synergy of a closed-loop feedback system, high-quality electric heating elements, and superior chamber insulation. This combination allows the furnace to not only reach a specific temperature but to maintain it with exceptional stability and uniformity, which is critical for sensitive material processing.

The key to precision is not just heating, but constant measurement and correction. Modern electric furnaces use PID (Proportional-Integral-Derivative) controllers that act as a digital brain, continuously monitoring the chamber temperature and making micro-adjustments to the power sent to the heating elements to eliminate any deviation from your setpoint.

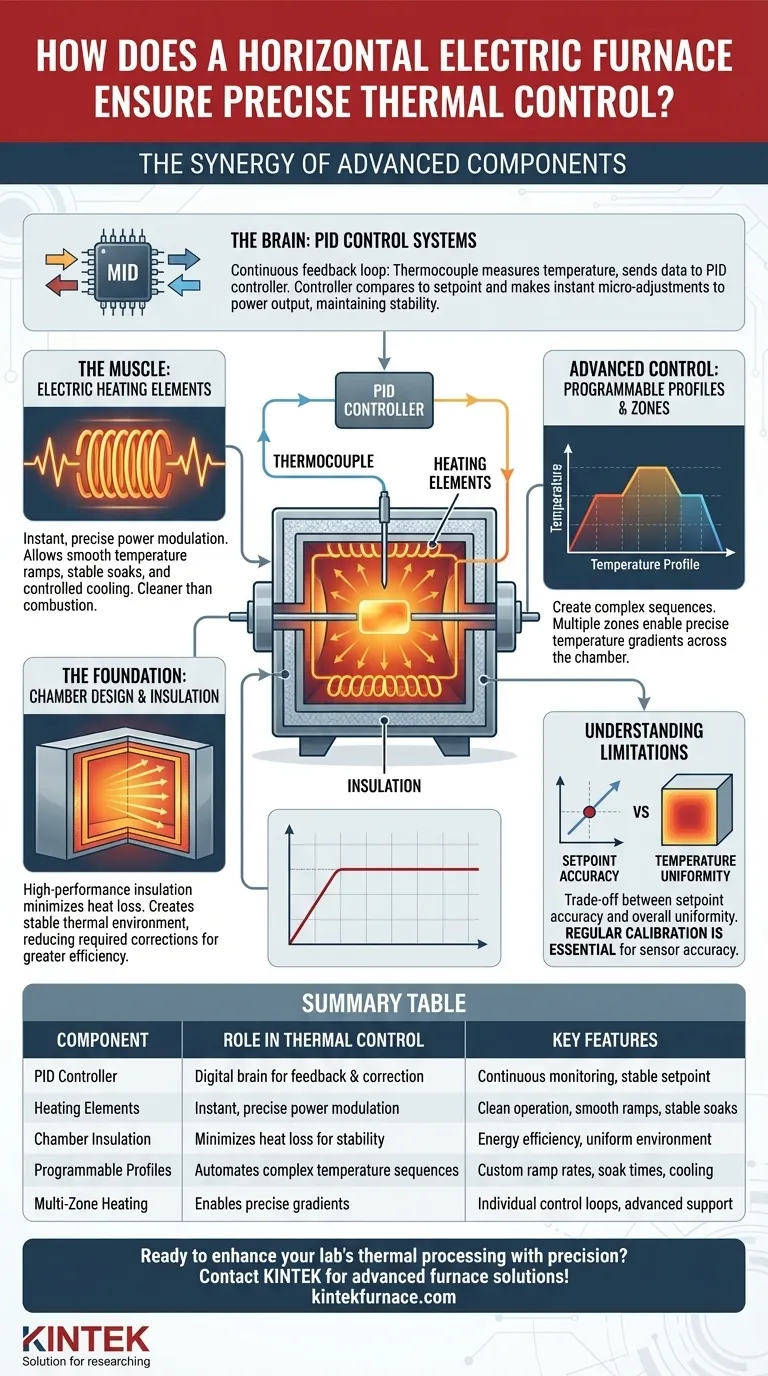

The Core Components of Thermal Precision

True thermal control is a result of several components working in concert. Understanding each part reveals how the furnace maintains such a stable and uniform environment.

The Brain: PID Control Systems

A PID (Proportional-Integral-Derivative) controller is the central nervous system of the furnace. It operates on a continuous feedback loop.

A thermocouple inside the chamber measures the actual temperature and sends this data to the PID controller. The controller compares this reading to the user-defined setpoint.

Based on the difference, it instantly calculates the precise amount of power the heating elements need, automatically adjusting their output to correct any deviation. This rapid response maintains thermal stability with minimal fluctuation.

The Muscle: Electric Heating Elements

Unlike combustion-based systems, electric heating elements offer inherently superior control. Their power output can be modulated instantly and precisely by the PID controller.

This allows for smooth temperature ramps, stable soaks at a set temperature, and controlled cooling. The absence of combustion also ensures a cleaner processing environment free from contaminants.

The Foundation: Chamber Design and Insulation

Precision is impossible without stability. High-performance insulation is critical for minimizing heat loss to the surrounding environment.

By preventing temperature leaks, the insulation creates a highly stable thermal environment. This means the PID controller has to make fewer and smaller corrections, resulting in tighter temperature control and greater energy efficiency.

Advanced Control: Programmable Profiles and Zones

Modern furnaces allow users to create complex thermal profiles, programming specific ramp rates, soak times, and cooling sequences. This automates intricate processes that require precise temperature changes over time.

For even greater control, some furnaces feature multiple heating zones. Each zone has its own heating elements and control loop, allowing you to create a precise temperature gradient across the length of the chamber, a requirement for many advanced research and production applications.

Understanding the Practical Limitations

While highly precise, no system is perfect. Understanding the trade-offs is key to selecting and operating the right equipment for your needs.

Setpoint Accuracy vs. Temperature Uniformity

Setpoint accuracy refers to how well the furnace holds the temperature at the specific point where the control thermocouple is located. Temperature uniformity, however, describes how consistent that temperature is across the entire volume of the chamber.

A furnace can have excellent setpoint accuracy but poor uniformity if its design does not promote even heat distribution. For processes involving large or multiple parts, uniformity is often more critical than setpoint accuracy alone.

The Role of Calibration

The entire control system relies on the data from its temperature sensor (thermocouple). The system's accuracy is only as good as the sensor's accuracy.

Regular calibration of the thermocouple against a known standard is essential to ensure the temperature you set is the temperature you are actually getting.

The Cost of Precision

As features like enhanced uniformity, multi-zone control, and advanced programming capabilities are added, the complexity and cost of the furnace increase. It is a direct trade-off between performance requirements and budget.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its capabilities to your specific processing needs. Consider the following guidelines to make an informed decision.

- If your primary focus is basic heat treatment (e.g., annealing, tempering): A single-zone furnace with a reliable PID controller and good insulation will provide the necessary stability.

- If your primary focus is sensitive material processing (e.g., sintering, crystal growth): Prioritize a furnace with documented high temperature uniformity and programmable profiling capabilities.

- If your primary focus is advanced research or complex production: A multi-zone furnace is essential for creating and controlling precise thermal gradients across your sample.

By understanding how these systems work together, you can confidently select and operate a furnace that delivers the exact thermal performance your process demands.

Summary Table:

| Component | Role in Thermal Control | Key Features |

|---|---|---|

| PID Controller | Acts as a digital brain for feedback and correction | Continuous monitoring, micro-adjustments, stable setpoint maintenance |

| Electric Heating Elements | Provide instant, precise power modulation | Clean operation, smooth ramps, stable soaks |

| Chamber Insulation | Minimizes heat loss for stability | Energy efficiency, reduced corrections, uniform environment |

| Programmable Profiles | Automates complex temperature sequences | Custom ramp rates, soak times, cooling control |

| Multi-Zone Heating | Enables precise gradients across the chamber | Individual control loops, advanced research support |

Ready to enhance your lab's thermal processing with precision? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how our furnaces can deliver superior temperature control and efficiency for your sensitive material processing!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- What is the use of a quartz tube furnace? For High-Purity, Observable Material Processing

- How does sample handling differ between vertical and horizontal tube furnaces? Choose the Right Furnace for Your Lab