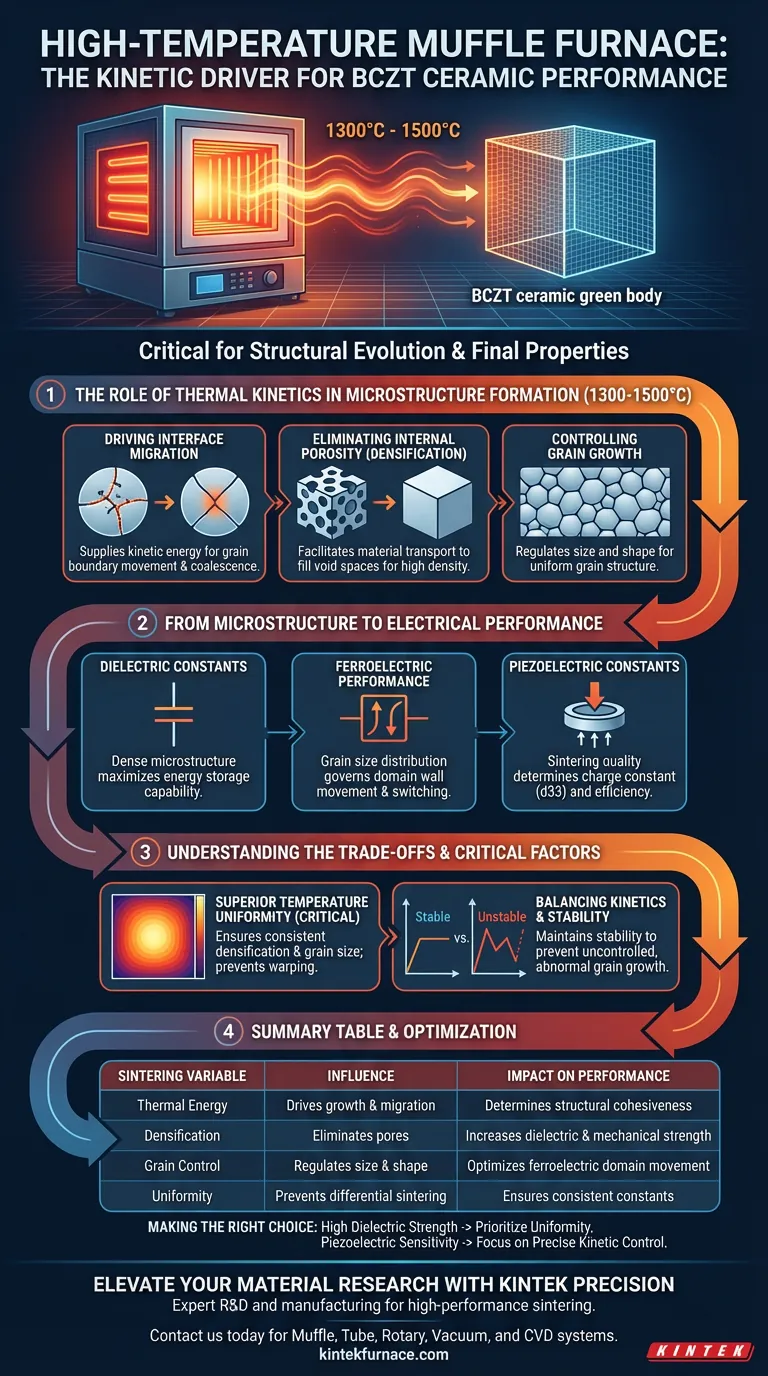

A high-temperature muffle furnace acts as the critical kinetic driver for the structural evolution of BCZT ceramics. Operating between 1300°C and 1500°C, the furnace provides the thermal energy required for grain growth, interface migration, and pore elimination. The precision and uniformity of this thermal environment directly dictate the material's final microstructure, which serves as the foundation for its dielectric, ferroelectric, and piezoelectric properties.

The furnace's primary influence lies in its ability to deliver superior temperature uniformity, which determines the degree of densification and grain size distribution. These microstructural factors are the physical prerequisites for achieving high-performance electrical constants in BCZT ceramics.

The Role of Thermal Kinetics in Microstructure Formation

Driving Interface Migration

The temperature range of 1300°C to 1500°C is not arbitrary; it is the specific window required to activate diffusion.

The furnace supplies the kinetic energy necessary for interface migration, allowing grain boundaries to move and grains to coalesce. This process is essential for transforming the loosely packed particles of the green body into a cohesive solid.

Eliminating Internal Porosity

A muffle furnace facilitates the elimination of pores, a process known as densification.

By maintaining high temperatures, the furnace creates the conditions for material transport that fills void spaces. Achieving high density is critical, as residual porosity interrupts the electric field and degrades the mechanical integrity of the ceramic.

Controlling Grain Growth

The thermal environment regulates the size and shape of the ceramic grains.

Proper kinetic conditions ensure that grains grow to an optimal size without becoming excessive or irregular. A uniform grain structure is vital for consistent macroscopic performance across the ceramic component.

From Microstructure to Electrical Performance

Determining Dielectric Constants

The microstructure developed in the furnace directly impacts the material's ability to store electrical energy.

A dense, well-sintered microstructure maximizes the dielectric constant. Conversely, a porous structure resulting from inadequate sintering would significantly lower this value.

Enhancing Ferroelectric Performance

The furnace's influence extends to the material's ability to switch polarization.

The specific grain size distribution achieved during the heating cycle governs the domain wall movement within the ceramic. This movement is the physical mechanism behind the material's ferroelectric response.

Optimizing Piezoelectric Constants

The final piezoelectric output is a function of the sintering quality.

The primary reference indicates that the kinetic conditions provided by the furnace determine the piezoelectric constants. Similar to related PZT ceramics, achieving near-theoretical density is required to maximize the charge constant (d33) and efficiency.

Understanding the Trade-offs

The Criticality of Temperature Uniformity

The most significant variable a furnace introduces is the uniformity of the thermal field.

If the furnace fails to provide superior temperature uniformity, the ceramic will suffer from differential sintering. This leads to regions of varying density and grain size, resulting in unpredictable electrical performance and potential structural warping.

Balancing Kinetics and Stability

While high temperatures drive necessary reactions, the furnace must maintain stability to prevent uncontrolled growth.

Excessive thermal fluctuations can lead to abnormal grain growth, where a few grains consume their neighbors. This creates a heterogeneous microstructure that degrades the mechanical strength and electrical reliability of the BCZT ceramic.

Making the Right Choice for Your Goal

To maximize the performance of BCZT ceramics, the furnace selection and operation must align with specific microstructural targets.

- If your primary focus is High Dielectric Strength: Prioritize a furnace with exceptional temperature uniformity to ensure maximum densification and the total elimination of porosity.

- If your primary focus is Piezoelectric Sensitivity: Focus on precise control of the kinetic conditions (temperature and time) to achieve the specific grain size distribution that optimizes domain wall mobility.

Ultimately, the high-temperature muffle furnace is the instrument that translates raw chemical potential into functional electrical performance through the precise control of microstructural evolution.

Summary Table:

| Sintering Variable | Influence on BCZT Ceramics | Impact on Final Performance |

|---|---|---|

| Thermal Energy | Drives grain growth and interface migration | Determines structural cohesiveness |

| Densification | Eliminates internal porosity and voids | Increases dielectric & mechanical strength |

| Grain Control | Regulates size and shape distribution | Optimizes ferroelectric domain movement |

| Uniformity | Prevents differential sintering & warping | Ensures consistent macroscopic constants |

Elevate Your Material Research with KINTEK Precision

To achieve superior electrical constants in BCZT ceramics, the precision of your thermal environment is non-negotiable. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet the rigorous demands of your lab's high-temperature sintering processes.

Our furnaces provide the superior temperature uniformity and kinetic control required to transform raw materials into high-density, high-performance functional ceramics. Contact us today to find the perfect sintering solution for your unique needs.

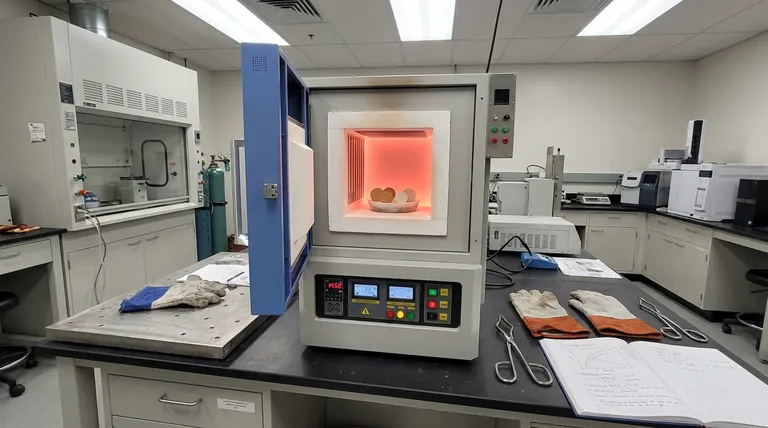

Visual Guide

References

- Baoyun Wang, Yongjun Tian. High-temperature structural disorders stabilize hydrous aluminosilicates in the mantle transition zone. DOI: 10.1038/s41467-025-56312-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the main advantages of using a muffle furnace? Achieve Precise, Contamination-Free Heating

- What should be considered when purchasing a box type electric furnace? Key Factors for Optimal Thermal Processing

- What are the energy efficiency features of modern digital muffle furnaces? Cut Costs with Advanced Insulation and Control

- Why is precise temperature control in a muffle furnace critical for 1250°C homogenization of AlCoCrFeNi alloys?

- What role does a high-temperature box furnace play in the secondary sintering and structural repair of recycled NCM?

- What is the most common format for Controlled Atmosphere Continuous Muffle Furnaces? Belt Furnace for High-Throughput Processing

- Why is a laboratory muffle furnace essential for the activation of catalysts? Optimize Your Catalyst Performance

- What function does a high-temperature muffle furnace serve during the calcination of GaN precursor resins? Purify GaN