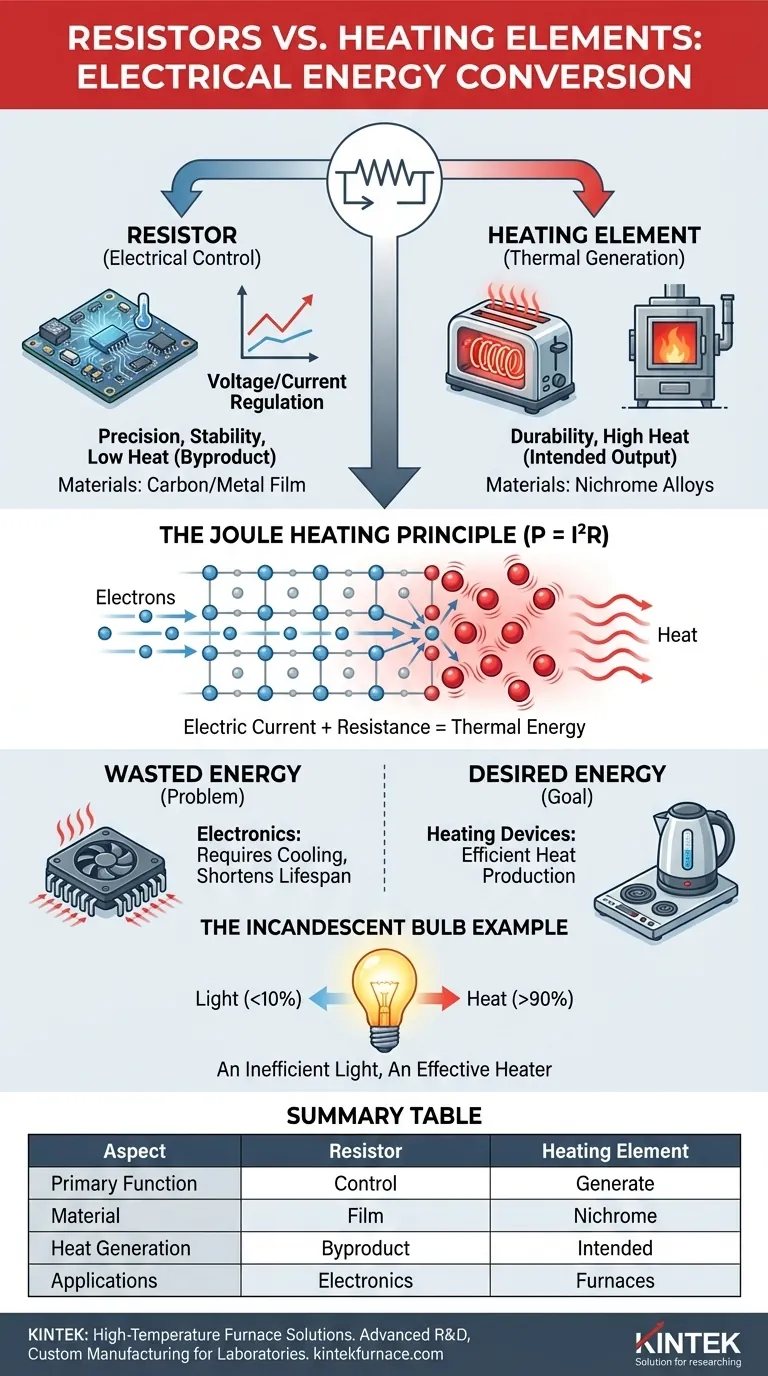

At its core, a heating element is a specialized type of resistor. Both components are designed to impede the flow of electric current, and in doing so, they convert electrical energy directly into heat. The fundamental difference between them lies not in what they do, but in their intended purpose and engineering.

While all resistors generate heat, a component is called a "heating element" when its primary, intended function is to produce heat. A standard "resistor" is used to control current or voltage, and the heat it produces is merely an unavoidable, often problematic, byproduct.

The Fundamental Principle: Joule Heating

The conversion of electrical energy into thermal energy in a resistor is a physical phenomenon known as Joule heating, or resistive heating. Understanding this principle is key to seeing why both components behave as they do.

How Current Creates Heat

When an electric current flows, it is essentially a stream of electrons moving through a material. As these electrons travel, they collide with the atoms of the resistive material.

Each collision transfers kinetic energy from the electron to the atom, causing the atom to vibrate more intensely. This increased atomic vibration is what we perceive and measure as heat.

The Role of Resistance

Resistance (R) is the measure of a material's opposition to the flow of electric current. A material with higher resistance will cause more electron collisions, and therefore generate more heat for a given amount of current.

This relationship is defined by the formula for power: P = I²R. Here, Power (P) is the rate of energy conversion (to heat), I is the current, and R is the resistance. This shows that heat generation increases exponentially with current and linearly with resistance.

Distinguishing Purpose and Design

Though they operate on the same principle, a resistor on a circuit board and a heating coil in a toaster are engineered for vastly different applications.

Intent: Electrical Control vs. Thermal Generation

The primary purpose of a standard resistor is to control electrical properties. It is used to limit current, divide voltage, or pull a signal to a specific level. Its job is purely electrical.

Conversely, the sole purpose of a heating element is to generate a significant amount of heat. Its electrical properties are secondary to its thermal output.

Materials and Construction

Resistors are built for precision and stability. They are often made from carbon film or metal film and are designed with a specific power rating, which indicates how much waste heat they can safely dissipate without being damaged.

Heating elements are built for thermal durability. They are typically made from alloys like Nichrome (nickel-chromium), which has high resistance and, critically, can withstand extremely high temperatures for long periods without oxidizing or melting. Their physical form is often a coil or ribbon to maximize the surface area for radiating heat effectively.

Understanding the Trade-offs: Desired vs. Wasted Energy

This dual nature of resistive heating—sometimes useful, sometimes detrimental—is a central challenge in all electrical and electronic design.

Heat as the Goal

In devices like electric stoves, water heaters, and toasters, Joule heating is the desired outcome. The entire system is engineered to deliver a controlled current to a heating element to produce a specific amount of heat safely and efficiently.

Heat as a Problem

In most other electronics, from your phone to a data center server, resistive heating is a source of waste and a potential point of failure. The energy converted to heat is energy that is not being used for computation or other work.

This waste heat raises the operating temperature of components, which can degrade their performance and shorten their lifespan. This is why complex systems require cooling solutions like heat sinks, fans, and liquid cooling to actively remove this unwanted thermal energy.

The Incandescent Bulb: A Perfect Example

The classic incandescent light bulb is a fascinating case study. It is, in effect, a heating element. It works by passing a current through a thin tungsten filament, heating it to a temperature so high (over 2,000°C) that it glows brightly (incandescence).

While the goal is light, over 90% of the electrical energy is converted directly into heat, not visible light. This makes it an extremely effective heater but a remarkably inefficient light source, which is why it has been almost entirely replaced by LEDs.

Making the Right Choice for Your Goal

Understanding this principle allows you to select the right components and design more effective systems. Your application dictates whether resistance is a tool to be used or a problem to be solved.

- If your primary focus is generating heat: You need a component specifically designed as a heating element, made from materials like Nichrome that can handle high power and temperatures.

- If your primary focus is controlling a circuit: You need a precision resistor and must calculate the heat it will generate (its power dissipation) to ensure it does not overheat and fail.

- If your primary focus is energy efficiency: You must strive to minimize unwanted resistance throughout your system to reduce power loss in the form of waste heat.

Mastering the conversion of electricity to heat is fundamental to designing everything from a simple circuit to a complex power grid.

Summary Table:

| Aspect | Resistor | Heating Element |

|---|---|---|

| Primary Function | Control current/voltage | Generate heat |

| Material | Carbon/metal film | Nichrome alloys |

| Heat Generation | Unwanted byproduct | Intended output |

| Applications | Circuit boards, electronics | Toasters, stoves, furnaces |

Need advanced heating solutions for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to enhance your thermal processes and achieve superior results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency