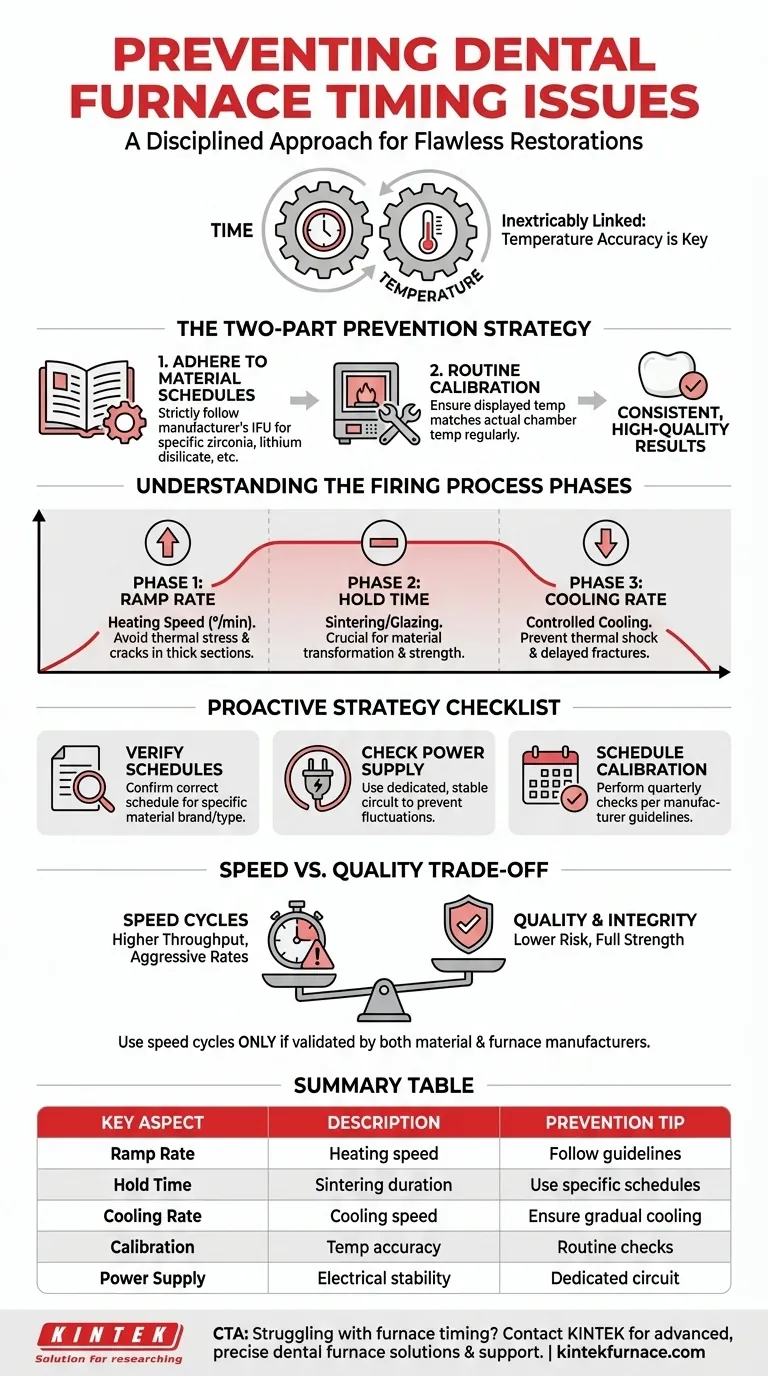

In short, preventing timing issues in a dental furnace requires a disciplined, two-part approach: strictly adhering to the manufacturer's recommended firing schedules for your specific material and implementing a routine calibration schedule to ensure the furnace's temperature is consistently accurate. Without correct temperature, even perfect timing settings will fail.

The core principle is that time and temperature are inextricably linked. A timing issue is often a symptom of a deeper problem, such as temperature inaccuracy or a mismatch between the firing cycle and the material's requirements. True prevention comes from treating the furnace, material, and firing schedule as one integrated system.

The Critical Link Between Time and Temperature

To prevent failures, you must first understand what "timing" truly means in a thermal process. It's not just about the total duration but about several distinct phases that work together with temperature.

Phase 1: Ramp Rate

The ramp rate is the speed at which the furnace heats up, measured in degrees per minute. An incorrect ramp rate—either too fast or too slow—introduces thermal stress into the restoration.

A ramp rate that is too aggressive can cause cracks, especially in thicker sections of a zirconia or ceramic restoration, because the outside heats much faster than the inside.

Phase 2: Hold Time (Sintering/Glazing)

The hold time is the period the furnace remains at its peak temperature. This is where the crucial material transformation, such as sintering, occurs.

Insufficient hold time results in incomplete sintering, leading to low strength, poor shade matching, and a chalky appearance. Conversely, excessive hold time can lead to oversized restorations or a loss of translucency.

Phase 3: Cooling Rate

The cooling rate is just as critical as the heating rate. If a restoration cools too quickly, the resulting thermal shock can cause it to fracture days or even weeks after it has been seated.

This is a common cause of mysterious failures, as the damage may not be immediately visible after the firing cycle is complete.

A Proactive Strategy for Flawless Firing

Preventing timing-related failures is not about reactive troubleshooting; it's about implementing a proactive system of checks and adherence to known standards.

Adhere to Material-Specific Firing Schedules

Every dental material, from zirconia to lithium disilicate, has a unique firing schedule developed by its manufacturer. These are not suggestions; they are precise instructions based on extensive research and development.

Always consult the Instructions for Use (IFU) for the exact material you are working with. Using the schedule for "Brand A" zirconia with "Brand B" zirconia is a primary cause of failure.

Implement Routine Furnace Calibration

A furnace's thermostat can drift over time. If your furnace is set to 1500°C but is only reaching 1475°C, your timing program is operating on false information. The material will be under-sintered even if the hold time is technically correct.

Calibration ensures that the temperature displayed on the screen matches the actual temperature inside the chamber. This should be performed regularly according to the furnace manufacturer's guidelines, typically using specialized calibration kits.

Verify Your Power Supply

Dental furnaces draw a significant amount of power. Inconsistent voltage or a shared circuit with other heavy equipment can cause the furnace to struggle to maintain its ramp rate or hold temperature.

This can silently disrupt the firing schedule, extending phases or causing temperature dips that compromise the final restoration. Ensure your furnace is on a dedicated, stable electrical circuit.

Understanding the Trade-offs: Speed vs. Quality

The demand for efficiency has led to the rise of "fast firing" or "speed" cycles. While tempting, using them without a full understanding of the trade-offs is a significant risk.

The Temptation of Fast Cycles

Shorter cycles mean higher throughput and faster case turnaround. Many modern furnaces and materials are marketed with this capability, promising full-strength restorations in a fraction of the traditional time.

Where Speed Compromises Integrity

Fast cycles use extremely aggressive ramp and cooling rates. While some new materials are designed to handle this, older materials or even thicker restorations made from "speed" materials can suffer from induced thermal stress.

This creates internal weaknesses that may not be visible but can lead to premature chipping or catastrophic fracture in the patient's mouth. The desire to save an hour in the lab can create a long-term clinical failure.

When to Safely Use Fast Cycles

Only use a speed cycle if both the material manufacturer and the furnace manufacturer explicitly approve it for your specific combination of equipment and material. Even then, it is wise to run test cycles on non-critical pieces to verify the results before applying the process to a patient case.

Making the Right Choice for Your Goal

Your operational protocols should be driven by your lab's primary objectives for quality, efficiency, and reliability.

- If your primary focus is maximum quality and consistency: Strictly adhere to the standard, non-speed firing schedules and implement a quarterly calibration schedule.

- If your primary focus is improving efficiency without risk: Only explore speed cycles that are explicitly validated by both your material and furnace manufacturers, and calibrate your furnace before adopting any new, faster schedule.

- If your primary focus is troubleshooting a specific failure: Begin by calibrating the furnace to eliminate temperature as a variable, then confirm you are using the exact firing schedule for the specific material brand and type.

By taking full control of your process variables, you can transform the firing cycle from a source of uncertainty into a predictable engine for high-quality restorations.

Summary Table:

| Key Aspect | Description | Prevention Tip |

|---|---|---|

| Ramp Rate | Speed of heating in degrees per minute | Follow manufacturer's guidelines to avoid thermal stress |

| Hold Time | Duration at peak temperature for sintering | Use material-specific schedules for complete transformation |

| Cooling Rate | Speed of cooling post-firing | Ensure gradual cooling to prevent fractures |

| Calibration | Accuracy of furnace temperature | Perform routine checks per manufacturer's recommendations |

| Power Supply | Stability of electrical input | Use a dedicated circuit to maintain consistent performance |

Struggling with dental furnace timing issues? KINTEK provides advanced high-temperature furnace solutions tailored for dental labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by strong deep customization capabilities to meet your unique experimental needs. With exceptional R&D and in-house manufacturing, we ensure precise temperature control and reliable performance for flawless restorations. Contact us today to enhance your lab's efficiency and quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations