In the ceramics industry, a muffle furnace is a specialized high-temperature oven used for critical thermal processes like firing and sintering. Its defining feature is an internal chamber, the "muffle," which isolates the ceramic material from the heating elements and their byproducts, ensuring a controlled, contamination-free environment.

The true value of a muffle furnace is not just its ability to generate high heat, but its capacity for absolute control. By creating a chemically pure and thermally uniform environment, it provides the non-negotiable foundation for developing and producing reliable, high-performance ceramic components.

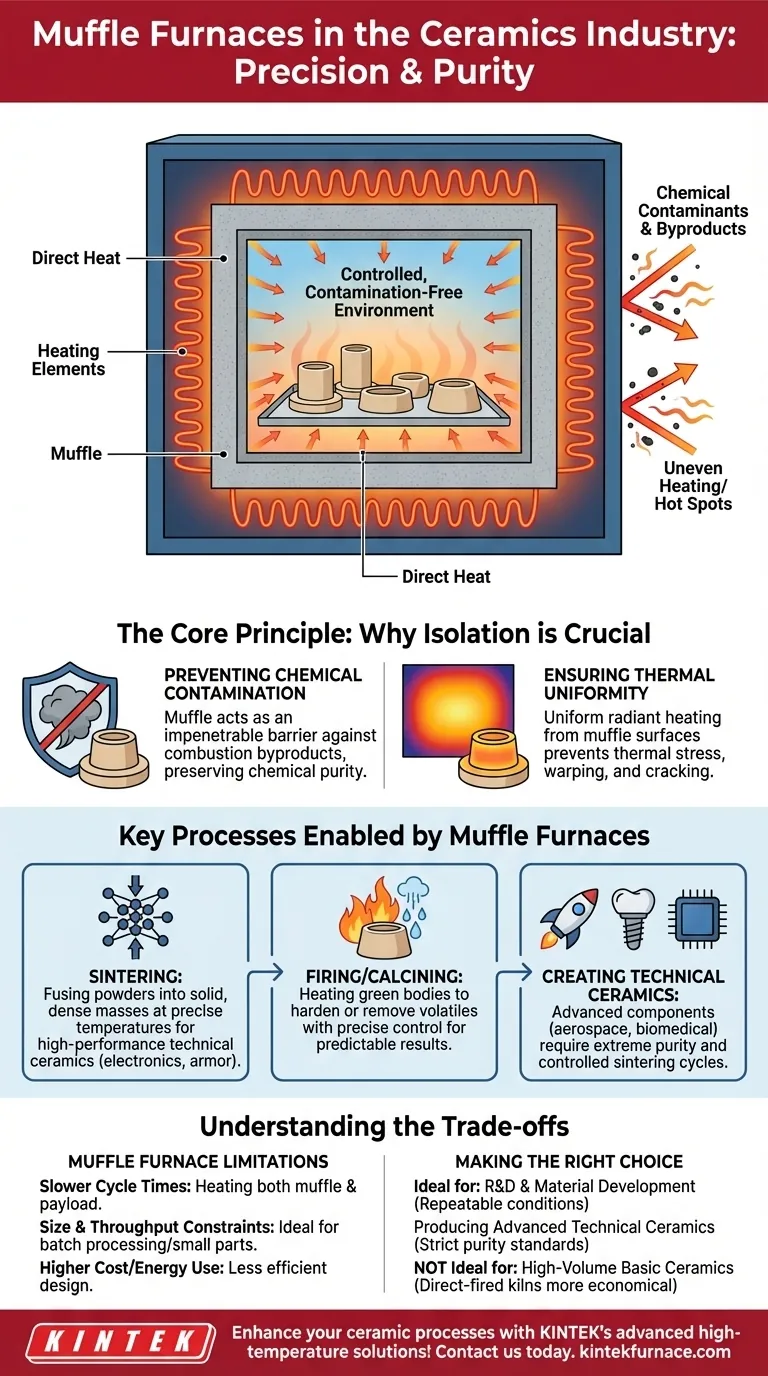

The Core Principle: Why Isolation is Crucial

The muffle furnace operates on a simple but powerful concept: creating a furnace within a furnace. This separation is the key to its utility in advanced ceramics.

What is a "Muffle"?

A muffle is a sealed or semi-sealed chamber made from a refractory ceramic material. This chamber is placed inside a larger, insulated furnace.

The heating elements (whether electric coils or gas burners) heat the outside of the muffle. The muffle then absorbs this energy and radiates it uniformly to the parts inside, ensuring even heating without direct exposure to the heat source.

Preventing Chemical Contamination

In many industrial furnaces, combustion byproducts like carbon, sulfur, or unburnt fuel can circulate in the atmosphere. Even in electric furnaces, the heating elements themselves can degrade and shed particles.

These contaminants can react with the ceramic material during firing, leading to discoloration, structural defects, and compromised technical properties. The muffle acts as an impenetrable barrier, preserving the chemical purity of the firing atmosphere.

Ensuring Thermal Uniformity

Direct exposure to heating elements can create hot spots on a ceramic part. This uneven heating causes thermal stress, which can lead to warping or cracking.

By radiating heat from all its surfaces, the muffle provides exceptionally uniform, indirect heating. This gentle, consistent temperature rise and fall is essential for the structural integrity of complex or sensitive ceramic pieces.

Key Processes Enabled by Muffle Furnaces

This combination of atmospheric purity and thermal control makes the muffle furnace essential for several high-stakes ceramic processes.

Sintering

Sintering is the process of fusing ceramic powders into a solid, dense mass using heat well below the material's melting point.

The precise temperature ramps and uniform heat of a muffle furnace are critical for achieving full densification without grain growth, resulting in strong, high-performance technical ceramics used in electronics, armor, and cutting tools.

Firing and Calcining

Firing is the general term for heating a "green" (unfired) ceramic body to harden it. Calcining is a specific thermal treatment used to remove volatile compounds like water or organic binders and to induce specific phase transformations in the material.

Both processes demand the precise temperature control offered by a muffle furnace to ensure predictable and repeatable results.

Creating Technical Ceramics

The production of advanced components for industries like aerospace, biomedical, and electronics relies on muffle furnaces.

Materials like alumina, zirconia, and silicon carbide require extremely high purity and controlled sintering cycles to achieve their desired dielectric, thermal, or mechanical properties. A muffle furnace provides the necessary controlled environment.

Understanding the Trade-offs

While indispensable, the muffle furnace is not the universal solution for all ceramic heating needs. Understanding its limitations is key to using it effectively.

Slower Cycle Times

The muffle itself is a significant thermal mass that must be heated and cooled along with the payload. This results in longer overall cycle times compared to direct-fired kilns, which can impact production throughput.

Size and Throughput Constraints

Traditional muffle furnaces are often designed for batch processing and are typically smaller than their industrial kiln counterparts.

They are ideal for research labs, quality control testing, or the production of smaller, high-value components. For mass production of bulk items like bricks or tiles, larger continuous kilns are more economical.

Higher Relative Cost and Energy Use

The "furnace-in-a-furnace" design is inherently less energy-efficient than a direct-fired system where heat is applied directly to the product. The initial equipment cost and ongoing operational costs can be higher.

Making the Right Choice for Your Goal

The decision to use a muffle furnace depends entirely on the required level of precision and purity for your specific ceramic application.

- If your primary focus is research and material development: A muffle furnace is essential for the repeatable, controlled conditions needed for accurate analysis and discovery.

- If your primary focus is producing advanced technical ceramics: The material isolation and thermal uniformity of a muffle furnace are non-negotiable to meet strict performance and quality standards.

- If your primary focus is high-volume production of basic ceramics: A larger, more energy-efficient continuous kiln (like a tunnel or roller hearth) is almost always the more cost-effective choice.

Ultimately, selecting the right thermal processing equipment is a critical decision that balances the need for atmospheric purity and precision against the demands of production volume and cost.

Summary Table:

| Process | Key Benefit | Common Applications |

|---|---|---|

| Sintering | Precise temperature control for full densification | Technical ceramics for electronics, armor, cutting tools |

| Firing/Calcining | Controlled atmosphere to remove volatiles | Hardening ceramic bodies, phase transformations |

| Technical Ceramics Production | High purity and thermal uniformity | Aerospace, biomedical, and electronic components |

Enhance your ceramic processes with KINTEK's advanced high-temperature solutions! Leveraging exceptional R&D and in-house manufacturing, we provide muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems with deep customization to meet your unique experimental needs. Contact us today to discuss how our furnaces can deliver precise, contamination-free heating for your high-performance ceramics.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites