In the automotive sector, horizontal furnaces are indispensable tools used for critical heat treatment processes that enhance the metallurgical properties of metal components. They are specifically utilized for carburizing, carbonitriding, and annealing to improve the strength, wear resistance, and overall durability of essential parts such as gears, shafts, bearings, and engine components.

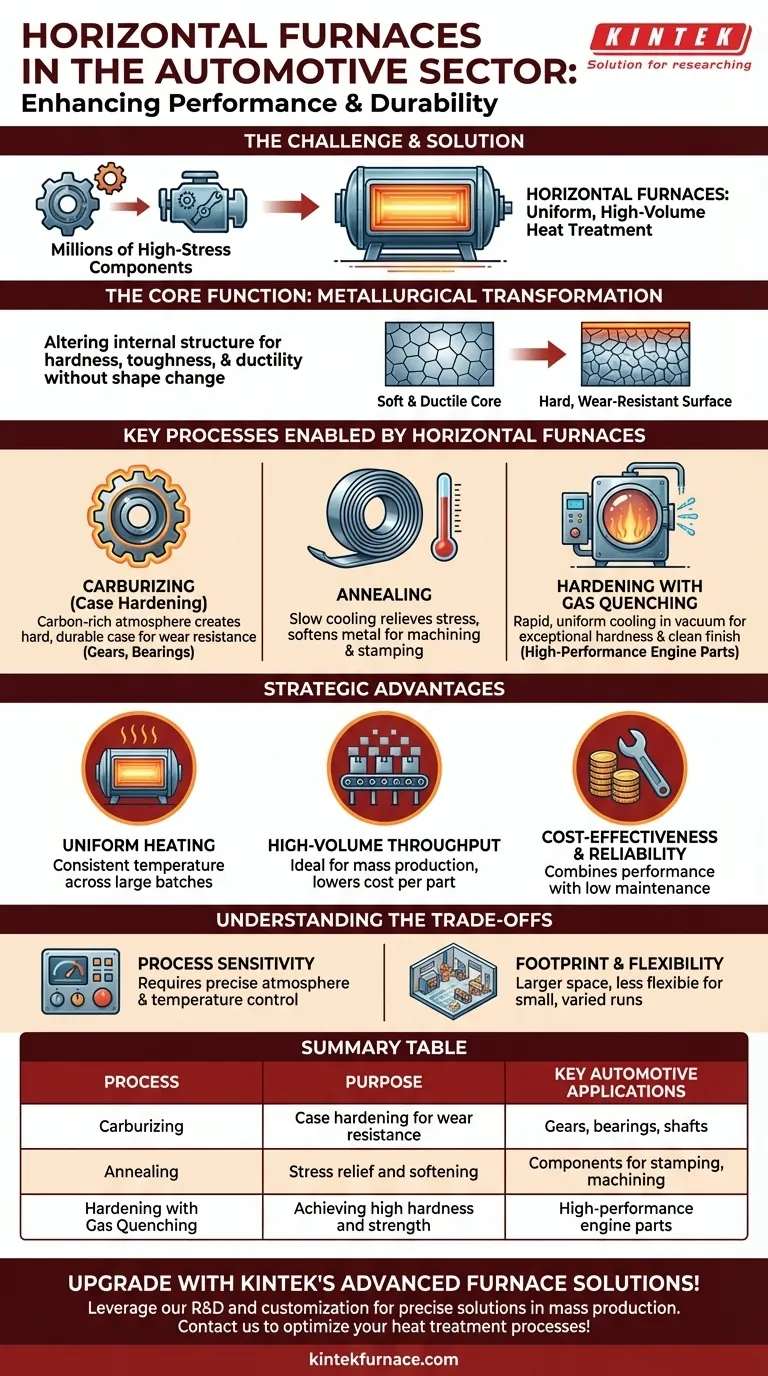

The core challenge in automotive manufacturing is producing millions of high-stress components that are both extremely durable and cost-effective. Horizontal furnaces solve this by enabling uniform, high-volume heat treatment, transforming standard metals into high-performance parts capable of withstanding years of demanding use.

The Core Function: Metallurgical Transformation

What is Heat Treatment?

Heat treatment is a controlled process of heating and cooling metals to alter their internal, microscopic structure. This modification changes the metal's physical and mechanical properties—such as hardness, toughness, and ductility—without changing its shape.

Why It Matters for Automotive Parts

Components like engine parts, gears, and shafts are subjected to immense stress, friction, and fatigue. Heat treatment creates parts with a dual nature: an extremely hard, wear-resistant surface to handle contact and friction, and a tougher, more ductile core to absorb shock and prevent catastrophic failure.

Key Processes Enabled by Horizontal Furnaces

Carburizing and Carbonitriding

These are case-hardening processes. Inside the furnace, a carbon-rich atmosphere allows carbon (and nitrogen, in carbonitriding) to diffuse into the surface of steel parts.

This creates a hard, durable outer layer, or "case," that is highly resistant to wear. This is a foundational process for manufacturing long-lasting gears and bearings.

Annealing

Annealing involves heating a metal to a specific temperature and then slowly cooling it. This process relieves internal stresses, softens the metal, and improves its ductility.

In the automotive industry, annealing is critical for preparing metal components for subsequent manufacturing steps like stamping or machining, ensuring they don't crack under strain.

Hardening with Gas Quenching

Modern horizontal vacuum furnaces are often paired with high-pressure gas quench systems. This setup allows for rapid, uniform cooling of heated parts in a controlled environment.

This process achieves exceptional hardness and strength while preventing the surface oxidation and distortion that can occur with older oil-quenching methods, making it ideal for high-performance engine parts.

Why Horizontal Furnaces Are a Strategic Choice

Uniform Heating

The horizontal configuration allows for consistent temperature distribution across a large batch of parts. This uniformity is critical for ensuring that every single component meets the strict quality and performance specifications required by the automotive industry.

High-Volume Throughput

The automotive industry operates on a massive scale. Horizontal furnaces are typically designed for large-volume batch processing, which aligns perfectly with mass production needs and helps lower the cost per part.

Cost-Effectiveness and Reliability

By combining high performance, large processing volumes, and relatively low maintenance requirements, horizontal furnaces provide a cost-effective and reliable solution for producing the vast quantities of treated parts the industry demands.

Understanding the Trade-offs

Process Sensitivity

The success of processes like carburizing is entirely dependent on precise control of the furnace's internal atmosphere and temperature. Any deviation or leak can compromise the integrity of an entire batch, leading to significant waste.

Footprint and Flexibility

Horizontal furnaces can require a substantial amount of factory floor space compared to some vertical designs. Furthermore, their batch-oriented nature, while great for mass production, can be less flexible than continuous furnaces for manufacturers handling a highly varied mix of small-run parts.

Making the Right Choice for Your Application

Selecting the right heat treatment process is driven entirely by the final performance requirements of the component.

- If your primary focus is mass-producing durable drivetrain components: Carburizing in a horizontal batch furnace is the industry standard for creating wear-resistant gears and bearings cost-effectively.

- If your primary focus is maximum hardness and a pristine surface finish: A horizontal vacuum furnace with high-pressure gas quenching is the superior choice for critical engine parts.

- If your primary focus is preparing metal for stamping or machining: The annealing capabilities of a horizontal furnace are essential for relieving internal stresses and improving formability.

Ultimately, the strategic application of horizontal furnaces is fundamental to manufacturing the safe, reliable, and high-performance vehicles we depend on.

Summary Table:

| Process | Purpose | Key Automotive Applications |

|---|---|---|

| Carburizing | Case hardening for wear resistance | Gears, bearings, shafts |

| Annealing | Stress relief and softening | Components for stamping, machining |

| Hardening with Gas Quenching | Achieving high hardness and strength | High-performance engine parts |

Upgrade your automotive manufacturing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique experimental needs, enhancing durability and efficiency in mass production. Contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition