While traditionally found in dental laboratories, a dental ceramic furnace can absolutely be used in a clinical setting. The decision hinges less on technical possibility and more on strategic fit. Its use in a clinic moves the practice toward a model of in-house fabrication, which comes with distinct benefits and significant operational responsibilities.

The core issue isn't whether a furnace can be in a clinic, but whether the benefits of in-house control and speed outweigh the complexities of cost, training, and maintenance. It is a strategic shift from outsourcing a specialized task to owning it entirely.

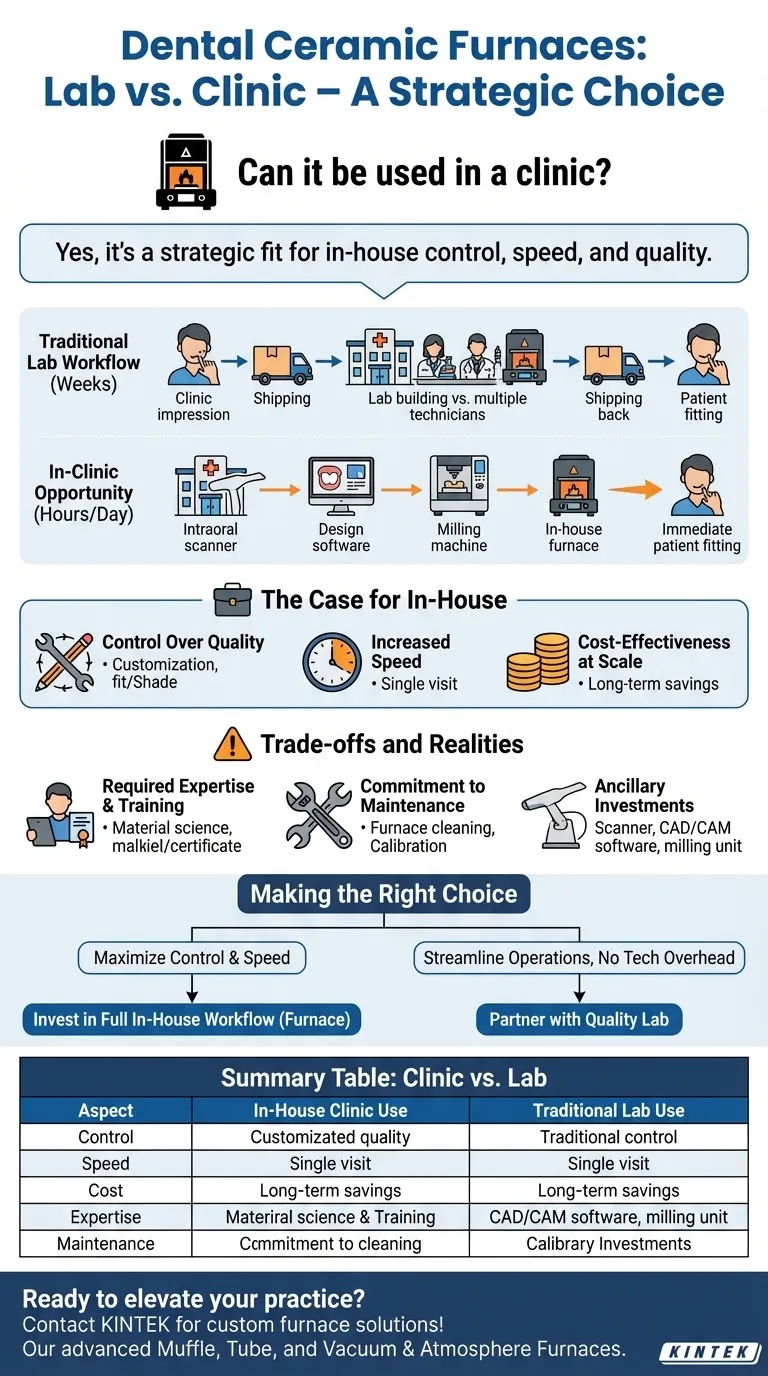

The Role of the Furnace: Lab vs. Clinic

Dental ceramic furnaces are precision instruments designed for one critical purpose: transforming ceramic materials into strong, aesthetic, and perfectly fitting dental restorations. This process is essential for creating crowns, bridges, and veneers.

The Traditional Laboratory Workflow

Traditionally, this work happens in a dedicated dental laboratory. The clinic takes impressions and sends the case to a lab, which employs technicians with specialized skills to fabricate the restoration.

These labs are built around high-volume, specialized production. Technicians are experts in handling various ceramic materials and programming the precise heating and cooling cycles required for each one.

The In-Clinic Opportunity

Placing a furnace in the dental clinic brings this fabrication process in-house. This is often part of a complete "chairside" digital dentistry workflow, where a patient can potentially receive their final restoration in a single visit.

This model gives the dentist direct oversight of the final product, from digital design to final glazing and placement.

The Case for an In-House Furnace

Adopting an in-house furnace offers compelling advantages that can fundamentally change a practice's efficiency and service offerings.

Gaining Control Over Quality

By managing the entire process, you have ultimate control over the final restoration's fit, shade, and contour. This allows for meticulous customization tailored perfectly to the individual patient without the back-and-forth communication with an external lab.

Increasing Speed and Patient Convenience

The most significant benefit is speed. Eliminating shipping time to and from a lab can reduce the turnaround for a crown from weeks to a single day or even hours. This is a powerful value proposition for patients.

Improving Cost-Effectiveness at Scale

While there is an initial investment, producing restorations in-house eliminates external lab fees. For practices with sufficient volume, this can lead to significant long-term cost savings and improved productivity.

Understanding the Trade-offs and Realities

Bringing a furnace into a clinical environment is not a simple plug-and-play decision. It requires a commitment to new processes and responsibilities.

The Required Expertise and Training

Operating a furnace is a technical skill. Different ceramic materials require specific firing programs, and improper handling can lead to failed restorations. Staff must be properly trained not just on the furnace, but on the entire material science workflow.

The Commitment to Maintenance

A furnace is a piece of high-performance equipment that demands regular upkeep to ensure accuracy and longevity. This includes routine cleaning of the firing chamber, calibration of temperature controls, and periodic inspection and replacement of components like thermocouples or heating elements.

The Ancillary Investments

The furnace itself is only one part of the equation. A full in-house workflow requires investments in digital scanning equipment (intraoral scanners), design software (CAD), and milling machines (CAM) to create the restoration that will be fired in the furnace.

Making the Right Choice for Your Practice

Ultimately, the decision to incorporate a dental ceramic furnace must align with your practice's specific goals and patient volume.

- If your primary focus is maximum control and single-visit restorations: Investing in a full in-house digital workflow, including a furnace, is a logical and powerful step.

- If your primary focus is streamlining clinical operations without adding technical overhead: Partnering with a high-quality, reliable dental laboratory remains the most efficient and practical path.

Aligning your technological investments with your operational strategy is the key to delivering the best possible care.

Summary Table:

| Aspect | In-House Clinic Use | Traditional Lab Use |

|---|---|---|

| Control | High control over fit, shade, and customization | Relies on external lab expertise |

| Speed | Single-visit restorations possible | Longer turnaround times (weeks) |

| Cost | Initial investment, long-term savings at scale | Ongoing lab fees per case |

| Expertise | Requires staff training on furnace and materials | Handled by specialized technicians |

| Maintenance | Regular upkeep needed for accuracy | Managed by the lab |

Ready to elevate your dental practice with in-house ceramic solutions? Contact us today to learn how KINTEK's advanced high-temperature furnaces, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, can be customized to fit your clinic's unique needs. Leveraging our exceptional R&D and in-house manufacturing, we help dental professionals achieve precise, efficient restorations with reliable support and deep customization capabilities.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations